Method for preparing bismuth oxide-lanthanum molybdate composite electrolyte by sol-gel self-combustion method

A composite electrolyte and sol-gel technology, which is applied in the field of solid electrolyte material preparation, can solve problems such as small temperature range, and achieve the effect of improved conductivity and high composite degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

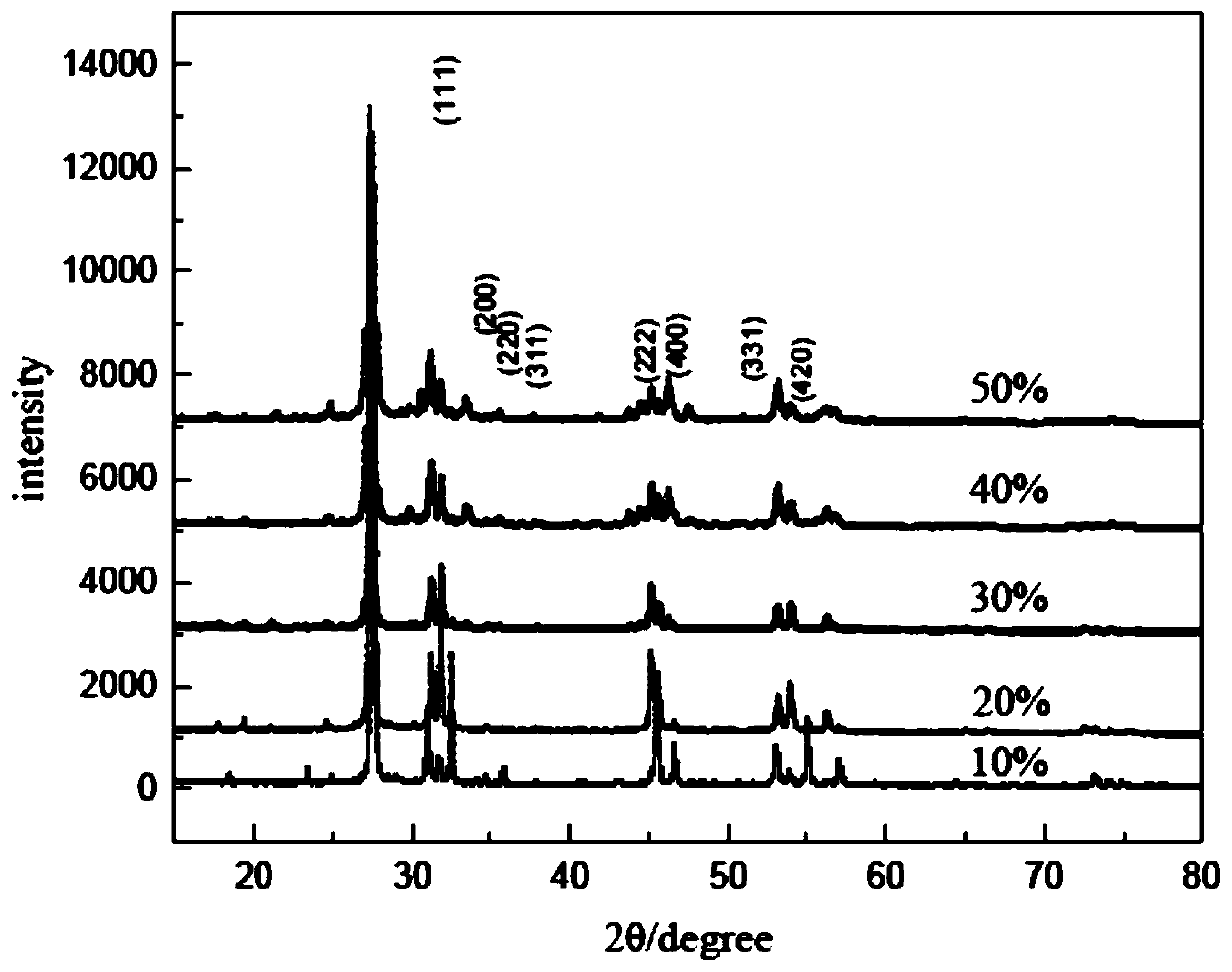

Image

Examples

Embodiment 1

[0030] A method for preparing a bismuth oxide-lanthanum molybdate composite electrolyte by a sol-gel self-combustion method, the steps are as follows:

[0031] ①、Sol-gel method to prepare lanthanum molybdate

[0032] First, 10 g of lanthanum nitrate and 5.6 g of ammonium molybdate were weighed and dissolved in 100 mL of water, and then 4 mL of ethylene glycol was added for acidification. Stir the solution evenly, put it into a beaker, then add a magnet and put it into a digital display magnetic stirrer, raise the temperature to 80 °C and start stirring, adjust the pH value to neutral with ammonia water during stirring, and then stir for 5h, After the water in the beaker has evaporated completely, the product needs to be put into an oven for drying. The temperature of the oven should be adjusted to above 80°C, and it needs to be dried for 6 hours to obtain lanthanum molybdate coarse powder.

[0033] ②, self-combustion method to purify lanthanum molybdate powder

[0034] After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com