A pressureless automatic jacking device and method

A jacking device and automatic technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, servo motors, etc., can solve the problems of high price of hydraulic working medium and difficult recycling of hydraulic working medium, and achieve recycling. and reuse, low environmental impact, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention is divided into a jacking mode, an unloading mode, a circulation mode and a regeneration mode during actual work.

[0034] Jacking mode:

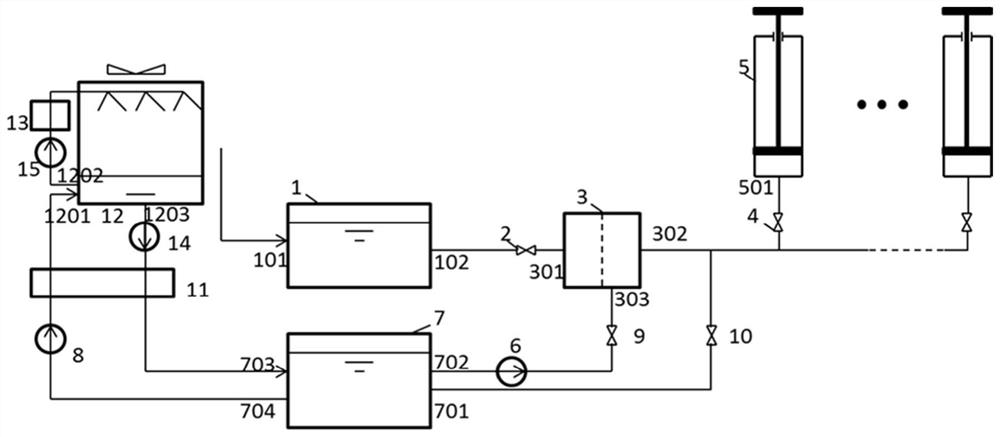

[0035] Open the pure water valve 2 and the liquid inlet valve 4 of all hydraulic cylinders that need to be lifted, and close the circulation pump outlet valve 9, the return valve 10 and other hydraulic cylinders that do not need to be lifted.

[0036] Put the heavy object on the jacking mechanism of the hydraulic cylinder 5, and under the action of the osmotic pressure of the hydraulic working medium in the forward osmosis tank 3, the water in the pure water tank 1 automatically enters the aqueous solution side through the forward osmosis membrane in the forward osmosis tank 3, At the same time, the pressure of the aqueous solution side of the forward osmosis tank and the connected hydraulic cylinder is increased. When the pressure is increased enough to lift the weight loaded by the jacking mechanism of the hyd...

Embodiment 2

[0045] The only difference between embodiment 2 and embodiment 1 is that the regenerator is removed, the regeneration mode is slightly different from embodiment 1, and the rest of the modes are the same.

[0046] regeneration mode

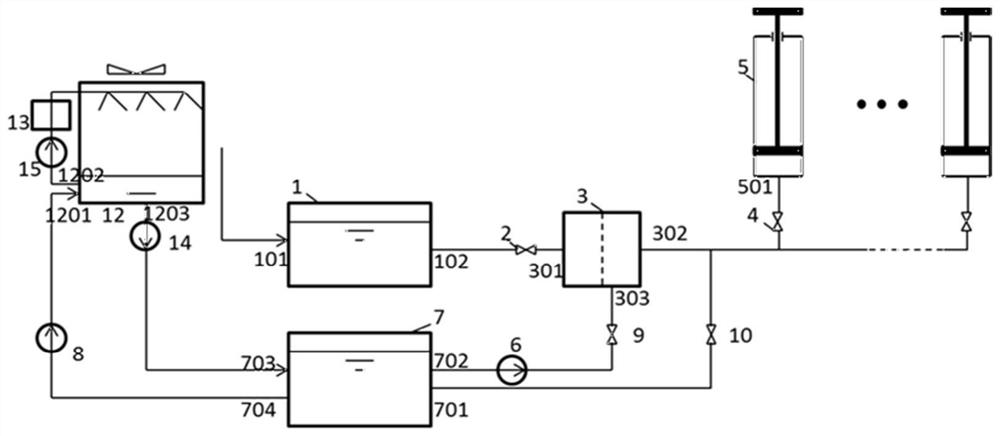

[0047] As the jacking mode and the unloading mode are repeated, the concentration of the aqueous solution in the solution tank gradually becomes thinner, and when the concentration is lower than the limit value, it enters the regeneration mode.

[0048] At this time, the aqueous solution flows out from the dilute solution outlet 704 of the solution tank 7, and after being pressurized by the dilute solution pump 8, enters the bottom of the regeneration tower 12 from the dilute solution inlet 1201 of the regeneration tower for storage. The solution in the regeneration tower 12 flows out from the circulating liquid outlet 1202, pressurized by the regeneration tower circulation pump 15, enters the heating channel of the heater 13, absorbs the heat prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com