Rope-rod combined driving type rocking-turn mechanism for steel smelting furnace

A hybrid drive and steelmaking furnace technology, applied in the manufacture of converters, etc., can solve the problems of poor mixing performance of molten iron and alloy materials, large reversing tilting impact torque, poor ability to remove impurities, etc., to achieve compact structure, reduce The impact torque of tilting and reversing, the effect of large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

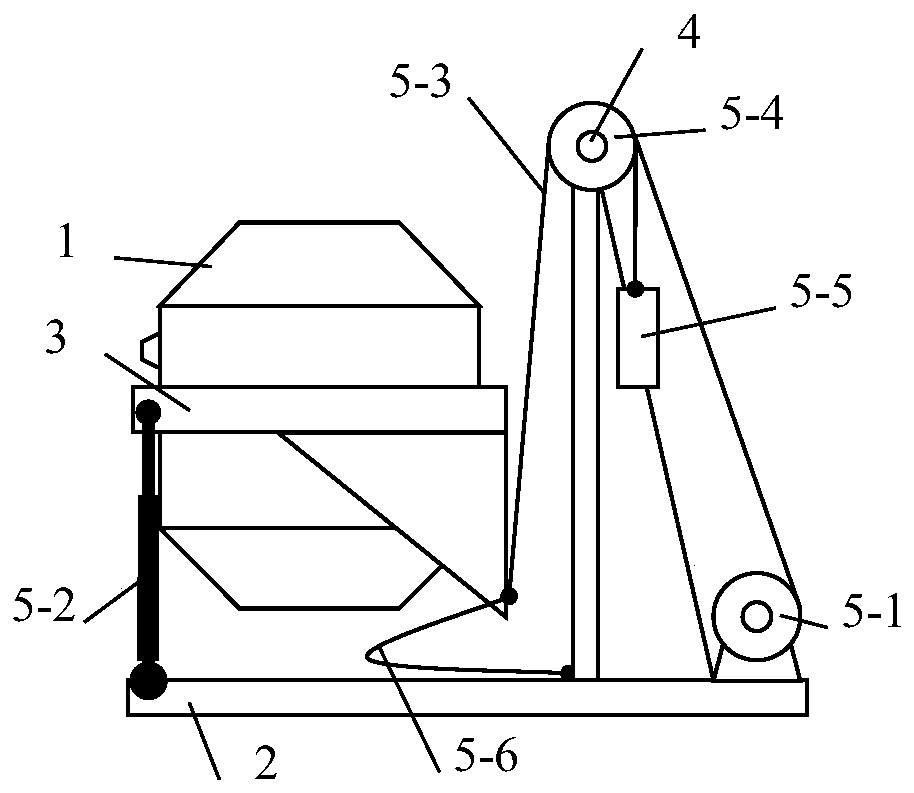

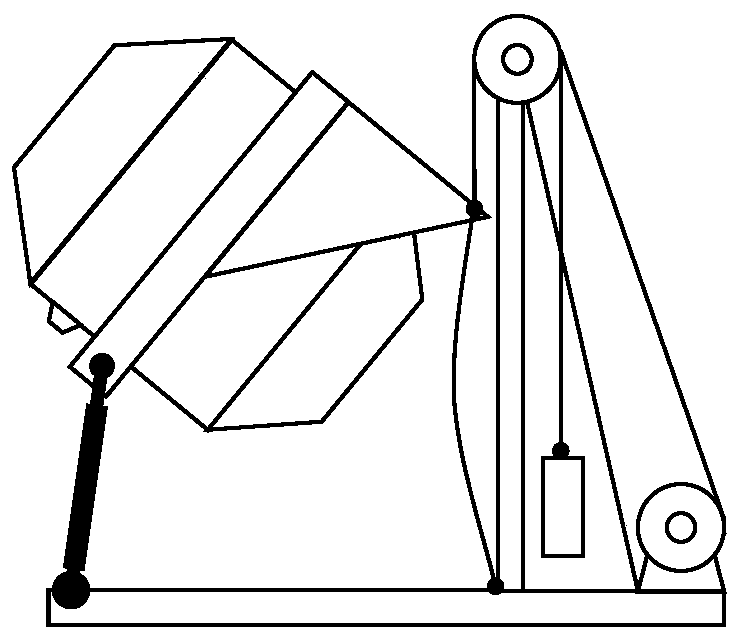

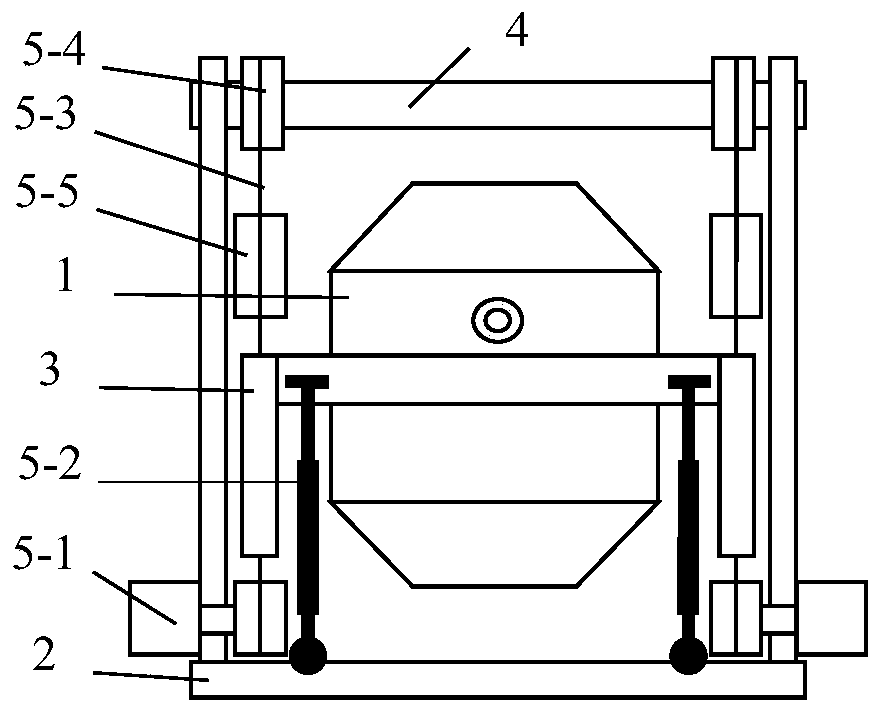

[0027] Further, as Figure 1-3 As shown, the present invention provides a rocking mechanism for a steelmaking furnace driven by a rope-and-rod hybrid drive, including a machine base 2, a moving table 3, a horizontal shaft 4, and two sets of identical rope-and-rod hybrid driving devices; the moving table 3 is provided with a central through hole , the left through hole and the lower right inclined plate tangent to the circumference of the large through hole, the steelmaking furnace 1 is fixedly connected with the central through hole of the moving table 3, and the steel tapping hole of the steelmaking furnace 1 is located at the left through hole side of the moving table 3; The base 2 is a bracket composed of a rectangular horizontal plate and two mutually parallel vertical plates. There are two symmetrical hinge seats on the horizontal plate. The upper and lower ends of the two vertical plates are provided with parallel through holes. The two ends of 4 are fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com