Pressure-resistant structure of deep submersible

A technology of pressure-resistant structures and submersibles, which is applied in the direction of hulls, ship construction, ships, etc., can solve the problems of pressure-resistant structure strength damage, etc., and achieve the effect of simple force-bearing form, simple structure, and reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

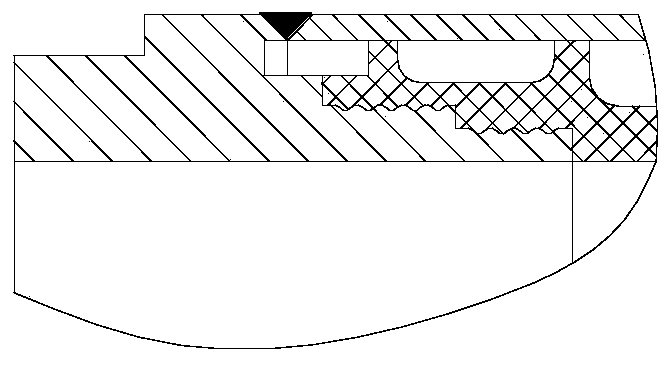

[0035] Such as figure 1 with figure 2 As shown, the pressure-resistant structure of the deep-depth submersible of the present invention includes a left flange 1, an inner shell 2, an outer shell 3, and a right flange 4.

[0036] The pressure-resistant structure of the deep submersible according to the present invention is a combined structure, and the inner shell 2 is wound on the basis of the left flange 1 and the right flange 4.

[0037] Preferably, the inner shell 2 is made of carbon fiber composite material.

[0038] The shell 3 is rolled of titanium alloy plate and welded by longitudinal welds. The shrinkage force of the welded shell 3 makes its inner wall closely fit the ring ribs of the inner shell 2. The shell 3 is then connected to the left flange 1 through the circumferential welds on both sides It is connected with the right flange 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com