Forging method for improving alpha-beta two-phase titanium alloy forging blank structure uniformity

A technology of uniform structure and titanium alloy, applied in the field of titanium alloy processing, can solve the problems of increasing the forging times and deformation, small forging deformation, and decreasing the yield of forging blanks, so as to improve the uniformity of the structure and reduce the forging times. , reducing the effect of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

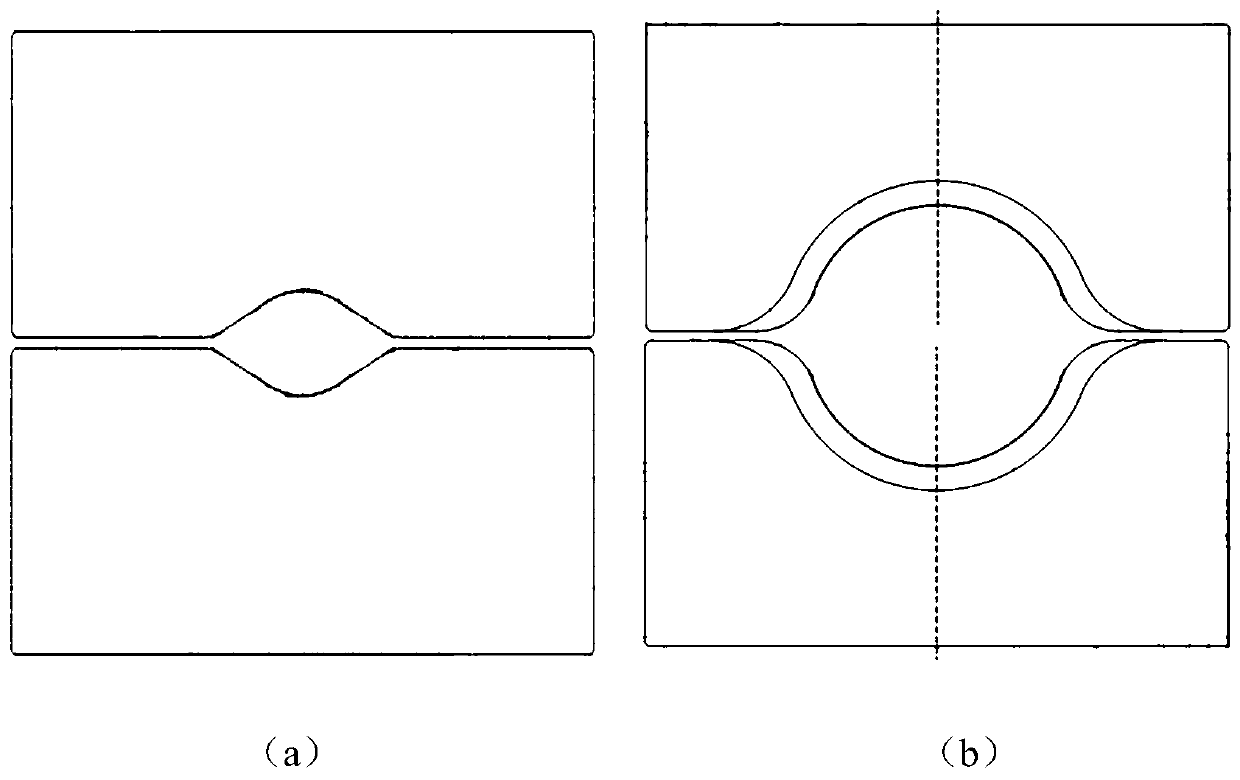

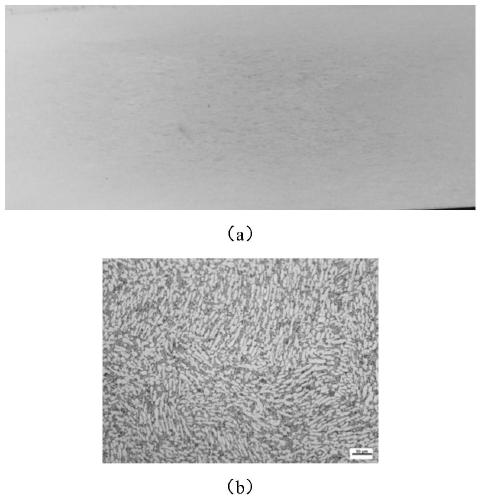

[0033] In this embodiment, the raw material is TC4 titanium alloy, and the phase transition point is 995° C. as measured by metallographic method. The original process of forging billets is the first type of forging process. The total number of fires is six fires. The first two fires are upsetting and drawing forging above the phase transition point temperature, and the last four fires are elongation forging below the phase transition temperature. The total deformation is 180%. The low-magnification structure of the billet is as figure 2 As shown in (a), the high-magnification microstructure of the forging billet is as follows figure 2 (b) shown. In this embodiment, a forging method is added between the third fire and the fourth fire in the conventional forging process of the first type of forging billet to homogenize the fire forging billet. This embodiment specifically includes the following steps:

[0034] Step 1. Select an appropriate size anvil according to the size ...

Embodiment 2

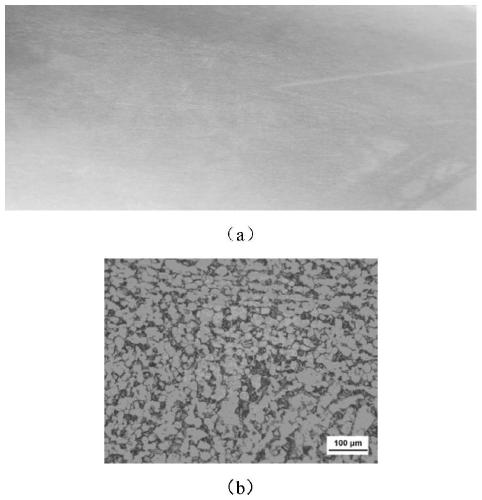

[0041]In this embodiment, the raw material is TC4 titanium alloy, and the phase transition point is 995° C. as measured by metallographic method. This embodiment is based on the existing second type of forging process. The original process of forging billets has eight fires in total, the first two fires are forging above the temperature of the phase transition point, and the third and fourth fires are continued below the phase transition point temperature. Upsetting and drawing forging are adopted, the fifth to eighth fires are elongated forging below the phase transition point temperature, the total deformation is 260%, and the high-magnification and low-magnification structures of the forging blank are as follows Figure 4 shown. In this embodiment, in the conventional forging process of the second type of forging billet, a forging method for increasing the uniformity of the structure of the two-fire gold forging billet is added. This embodiment specifically includes the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com