Integral combined tooth gear forging process with punching performed before combined tooth forming

A technology of gear forging and combining teeth, applied in the field of integral combined tooth gear forging technology, can solve the problems of large forming load and low die life, and achieve the effects of reducing forming load, improving service life and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

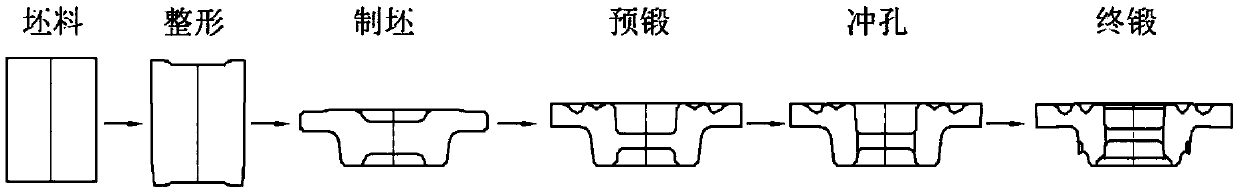

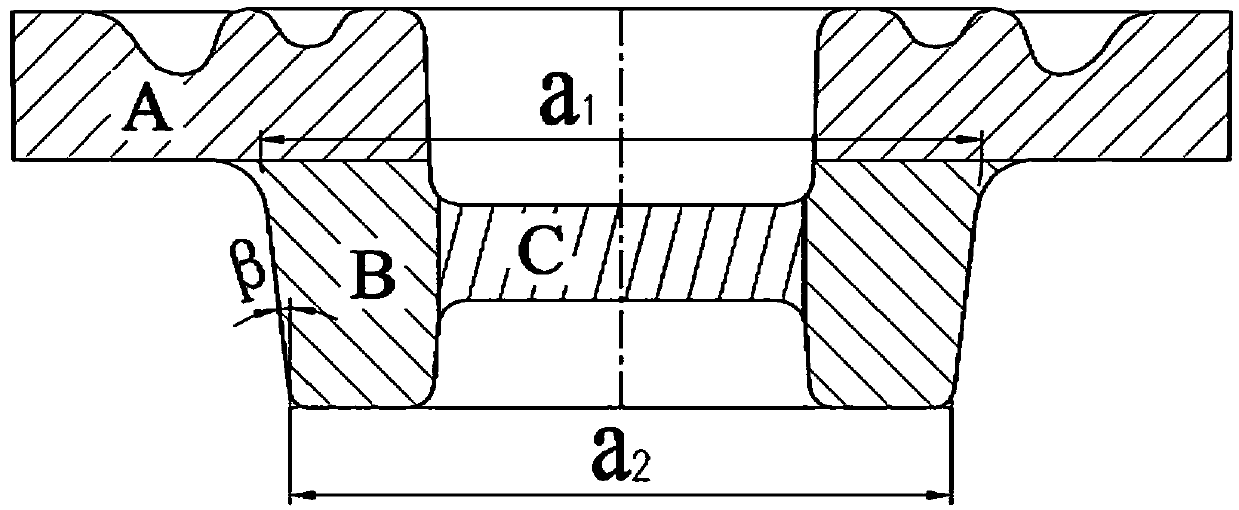

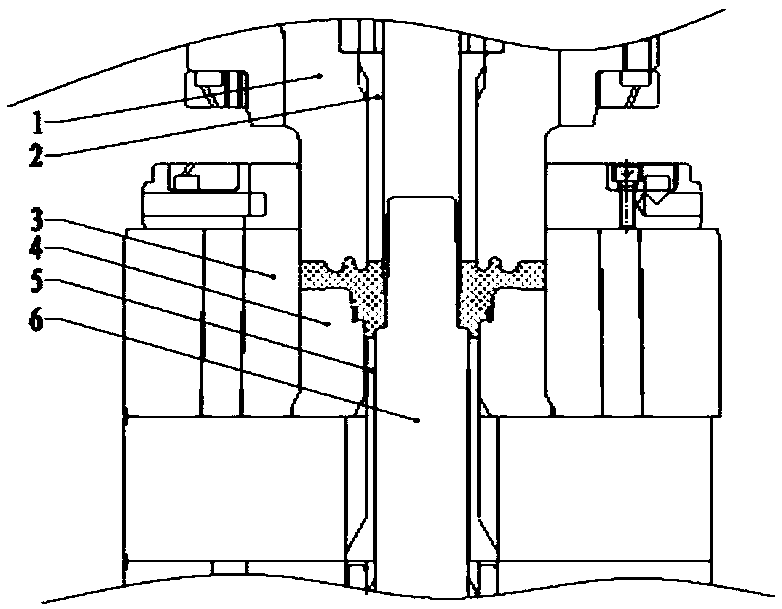

[0018] Such as figure 1 As shown, this embodiment takes the reverse gear driven gear in a certain automobile transmission as an example (the major diameter of the combined tooth is trail for Describe the forging process of the integral combined tooth gear that punches first and then forms the combined tooth.

[0019] This embodiment includes the following steps:

[0020] Cutting: According to the requirements of the reverse gear driven gear forging weight 1.832kg, select a cylindrical bar with a diameter of 60mm, calculate the length of the blank to be 82.54mm, use a circular saw for cutting, and control the cutting tolerance between 0-15g between;

[0021] Shot blasting: Use a drum type shot blasting machine with a steel shot diameter of 1.5mm to blast the blank, and the shot blasting time is set to 20 minutes;

[0022] Heating: Use a three-stage intermediate frequency heating furnace to heat the bar after shot blasting, and the heating temperature range is 1000±20°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com