Detection method for preventing printing mixing during SE battery production process

A technology of production process and detection method, applied in circuits, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve problems such as mixing, loss, and difficulty in observation, so as to achieve zero mixing in production lines and avoid losses. , to avoid the effect of a large number of mixed films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

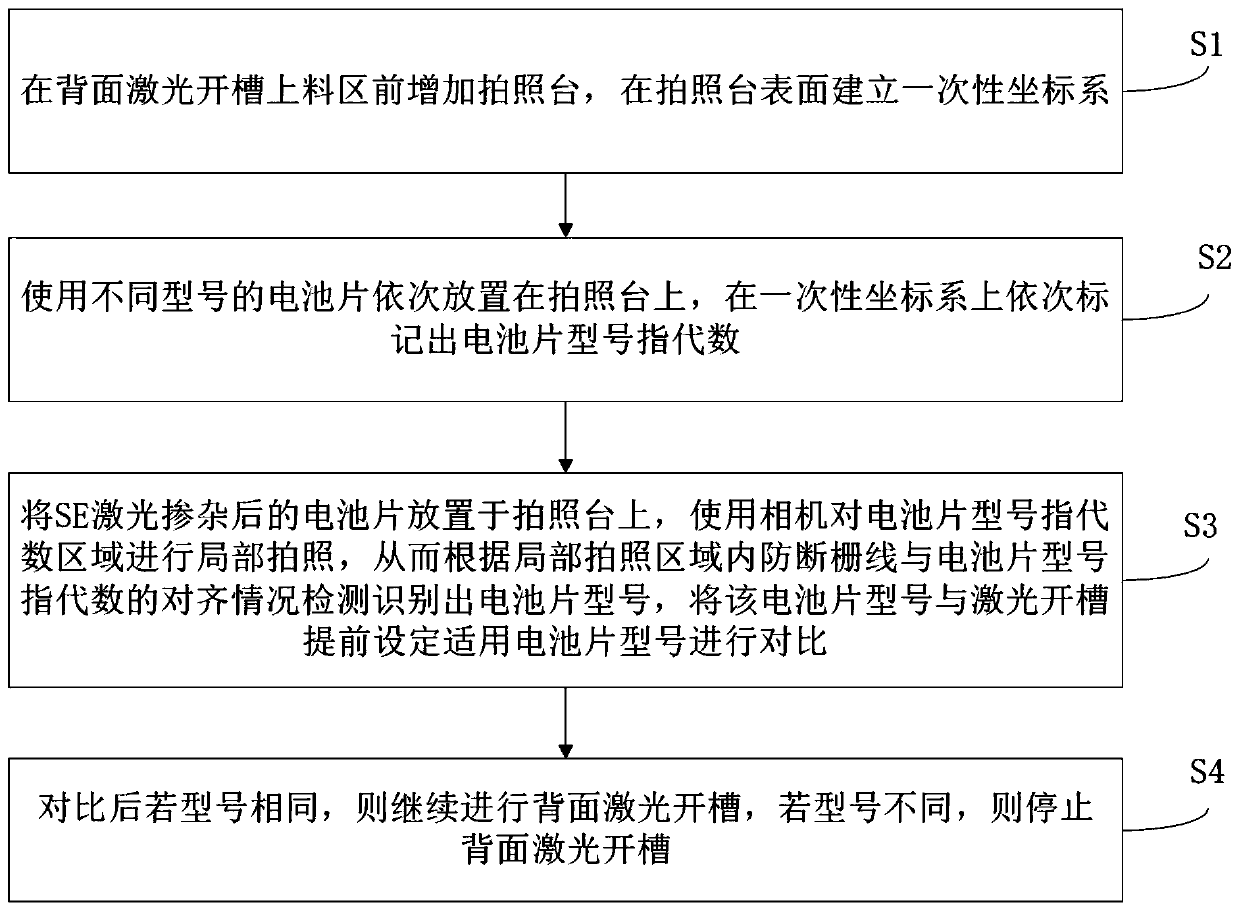

[0032] The production process steps of SE battery with model 4BB are as follows:

[0033] 1. Pre-cleaning and suede preparation of P-type silicon wafers;

[0034] 2. Preparation of P-N junction: use thermal diffusion to prepare phosphorus diffusion layer, adjust N 2 amount, oxygen flow rate, amount of phosphorus source, and diffusion temperature, to prepare the required high-resistance diffusion layer of 100-180Ω;

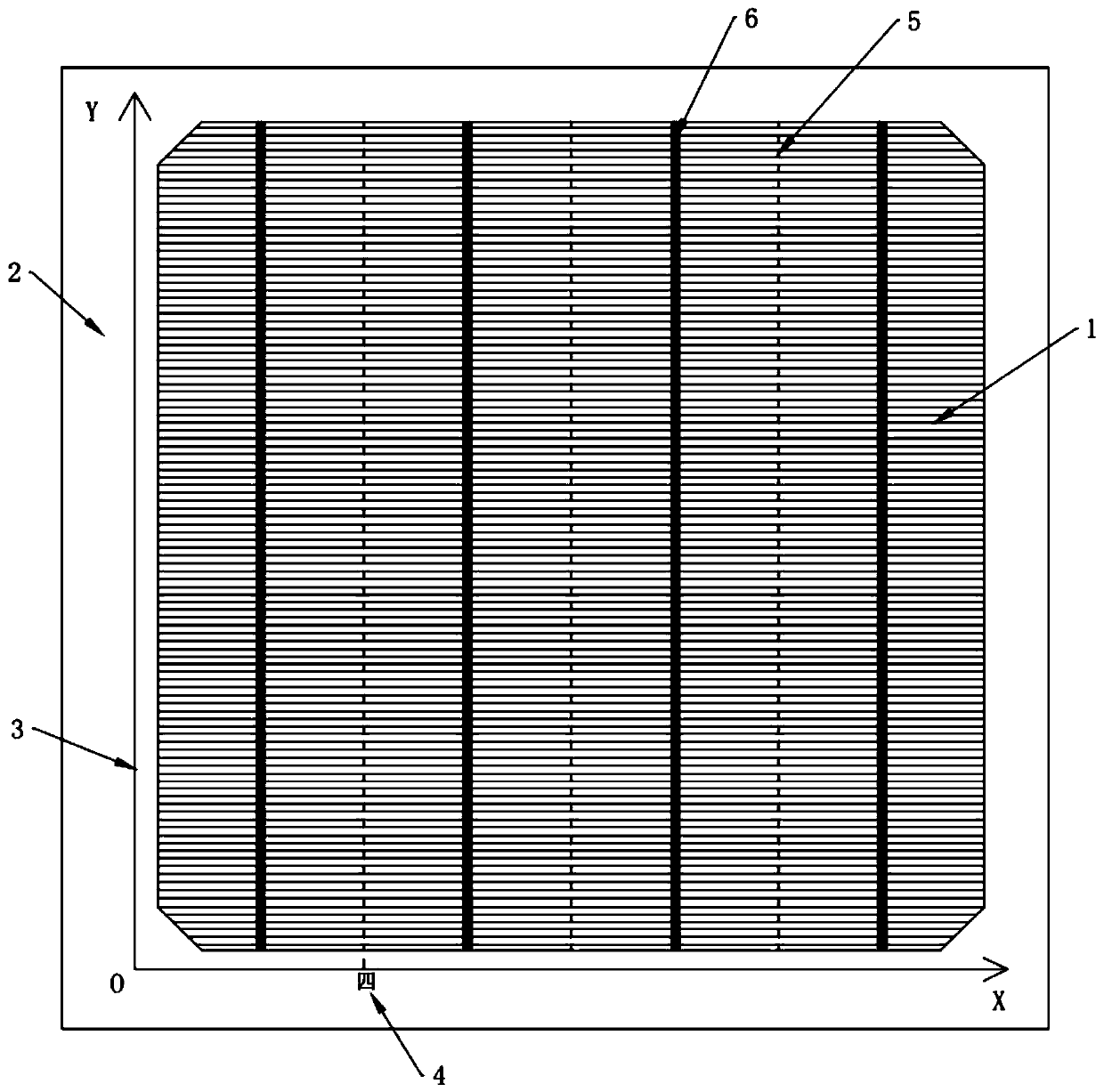

[0035] 3. SE laser doping: doping three anti-break grid lines 5 on the surface of the cell 1;

[0036] 4. Prepared by back etching to remove PSG, annealing, aluminum oxide passivation film and front and back SiNx layers;

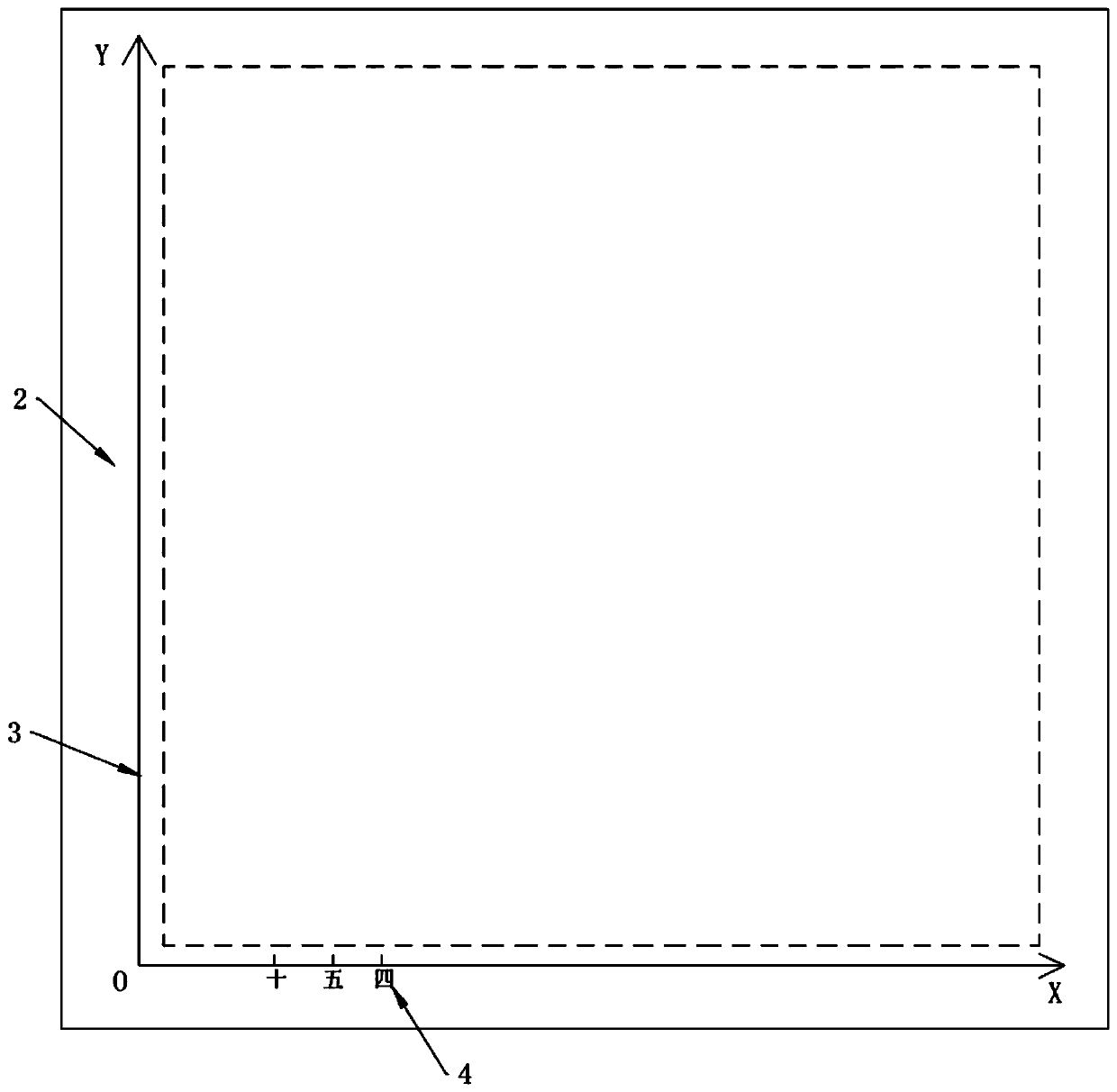

[0037] 5. Photo inspection steps: S1. Add a photo booth 2 before the laser slotting and loading area on the back, as attached to the manual figure 1 As shown, a dotted frame area with the same size as the cell 1 is set in advance on the photo stage 2 to place the cell 1, and a one-time coordinate system 3 is established on the surface of the p...

Embodiment 2

[0045] The production process steps of SE battery model 5BB are as follows:

[0046] 1. Pre-cleaning and suede preparation of P-type silicon wafers;

[0047] 2. Preparation of P-N junction: use thermal diffusion to prepare phosphorus diffusion layer, adjust N 2 amount, oxygen flow rate, amount of phosphorus source, and diffusion temperature, to prepare the required high-resistance diffusion layer of 100-180Ω;

[0048] 3. SE laser doping: doping four anti-break grid lines 5 on the surface of the cell 1;

[0049] 4. Prepared by back etching to remove PSG, annealing, aluminum oxide passivation film and front and back SiNx layers;

[0050] 5. Photo inspection steps: S1. Add a photo booth 2 before the laser slotting and loading area on the back, as attached to the manual figure 1 As shown, a dotted frame area with the same size as the cell 1 is set in advance on the photo stage 2 to place the cell 1, and a one-time coordinate system 3 is established on the surface of the photo s...

Embodiment 3

[0058] The steps of the production process of the SE battery whose model is a shingled module are as follows:

[0059] 1. Pre-cleaning and suede preparation of P-type silicon wafers;

[0060] 2. Preparation of P-N junction: use thermal diffusion to prepare phosphorus diffusion layer, adjust N 2 amount, oxygen flow rate, amount of phosphorus source, and diffusion temperature, to prepare the required high-resistance diffusion layer of 100-180Ω;

[0061] 3. SE laser doping: Doping ten anti-break grid lines 5 on the surface of the cell 1;

[0062] 4. Prepared by back etching to remove PSG, annealing, aluminum oxide passivation film and front and back SiNx layers;

[0063] 5. Photo inspection steps: S1. Add a photo booth 2 before the laser slotting and loading area on the back, as attached to the manual figure 1 As shown, a dotted frame area with the same size as the cell 1 is set in advance on the photo stage 2 to place the cell 1, and a one-time coordinate system 3 is establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com