Micro force sensor integrated with sensitive membrane and force transmission guiding rod and processing method thereof

A technology of micro force sensor and force transmission guide rod, which is applied in the field of sensors, can solve the problems of reducing force transmission sensitivity, cumbersome installation, and difficulty, and achieve the effects of simplifying the preparation process and installation process, improving measurement accuracy, and eliminating installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

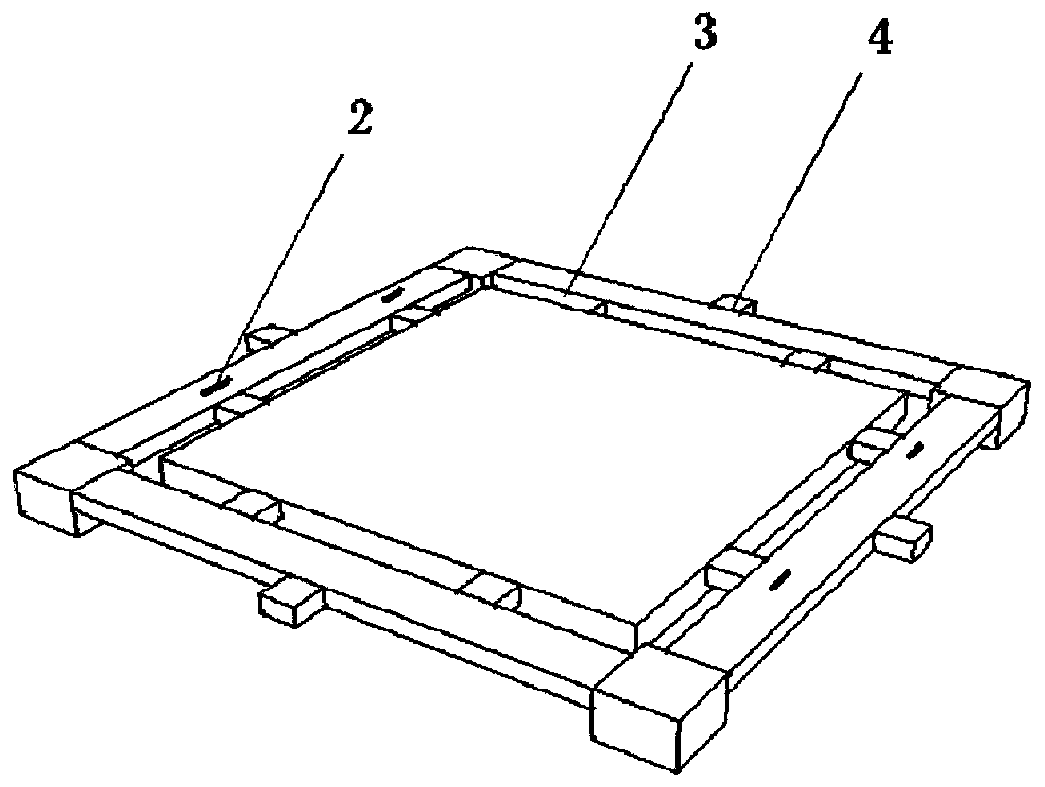

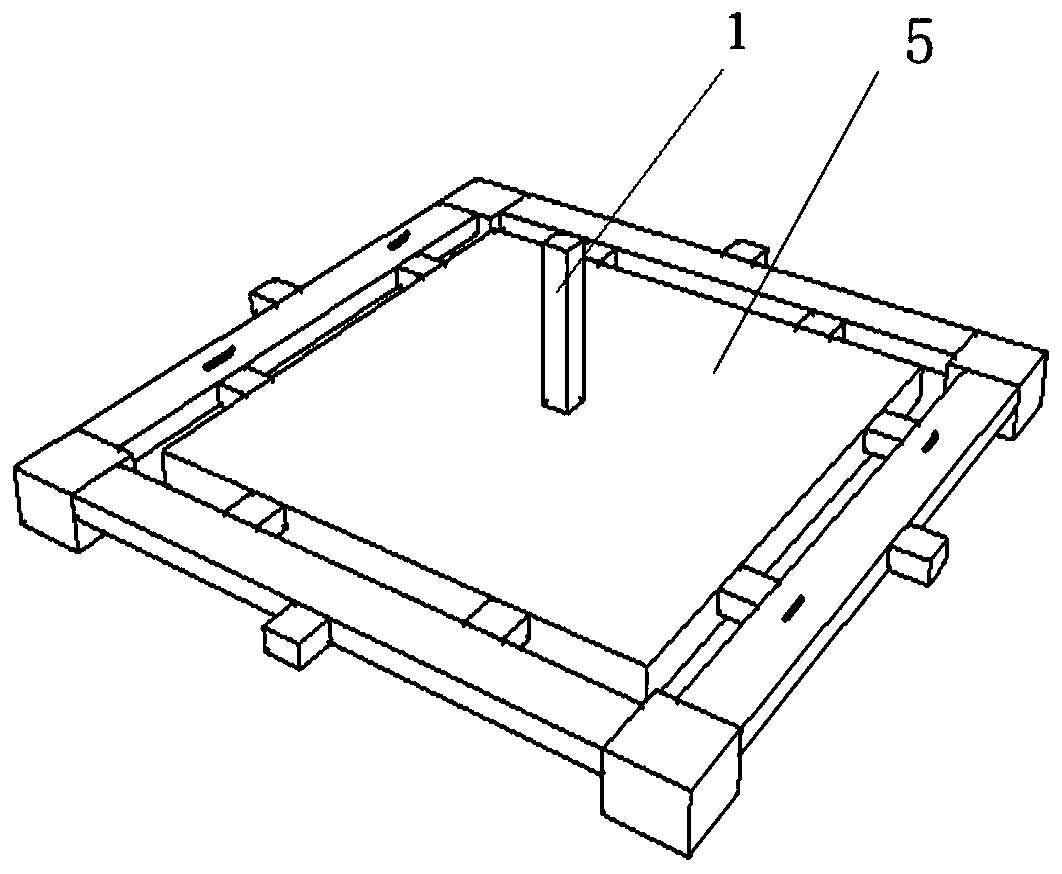

[0033] This embodiment provides a micro force sensor integrated with a sensitive membrane and a force transmission guide rod, including a fixedly connected sensitive membrane and a force transmission guide rod 1 . Such as figure 1 As shown, the sensitive film includes a central plate 5, a cantilever beam connected around the central plate 5, and a piezoresistor 2 arranged on the cantilever beam 4, and metal leads connect the piezoresistors to each other to form a Wheatstone bridge; among them, such as figure 1 As shown, the cantilever beam 4 includes four load beams 41 parallel to the edge of the center plate 5 and a connecting beam 42 connected between the load beams 41 and the center plate 5; each load beam 41 is connected to the center plate through two connecting beams 42 5 connections, each of the four load beams 41 is provided with two piezoresistors 2, so there are eight piezoresistors 2 in this embodiment; the load beams 41 are provided with contact holes matching the...

Embodiment 2

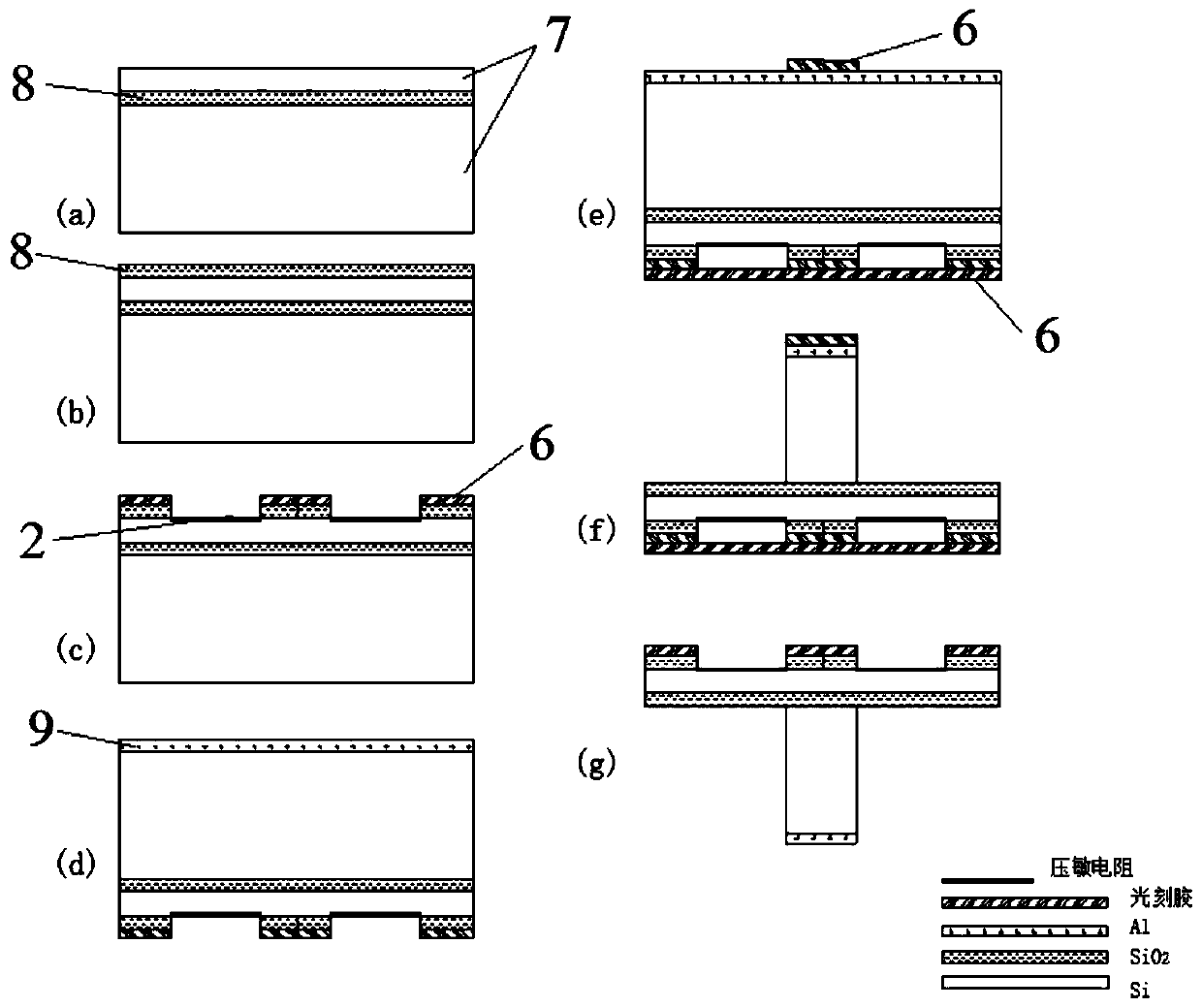

[0039] This embodiment provides a method for manufacturing the micro force sensor with the structure of Embodiment 1, the processing process is as follows image 3 As shown, the method includes the following steps:

[0040] 1. Processing of varistor 2

[0041] Select a 1mm thick SOI silicon wafer, clean and dry it. The silicon wafer includes a front monocrystalline silicon with a thickness of 30 μm, a silicon dioxide buried layer and a 950 μm rear monocrystalline silicon, in which the monocrystalline silicon is all N type monocrystalline silicon, such as image 3 (a) Si 7-SiO shown 2 The structure of 8-Si 7 is cleaned and dried; a 0.3um silicon dioxide film is formed on the front single crystal silicon of the SOI silicon wafer by thermal oxidation, such as image 3 SiO shown in (b) 2 8 structure; use the varistor plate to photoetch the varistor area on the silicon dioxide film, remove the silicon dioxide film in the varistor area on the silicon dioxide film, and expose t...

Embodiment 3

[0048] This embodiment is a micro-force sensor integrated with a sensitive film and a force transmission guide rod. Its main structure is the same as that of Embodiment 1, except that the force transmission guide rod is a cylindrical structure.

[0049] The specification parameters of the SOI silicon wafer used in the preparation process are: the thickness of the SOI silicon wafer is 0.5 mm, the thickness of the front monocrystalline silicon is 30 μm, and the thickness of the rear monocrystalline silicon is 400 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com