Large span low electromagnetic loss planar membrane structure

A low-electromagnetic, planar film technology, applied in building components, building structures, building insulation materials, etc., can solve the problem that the projected area of steel structure skeleton is relatively large, the effective area of transparent electromagnetic is affected, and the performance of electromagnetic wave transmission cannot be satisfied. problems, to achieve the effect of improving wind load resistance, ensuring length and width dimensions, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

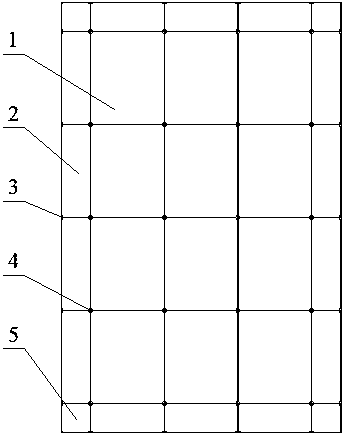

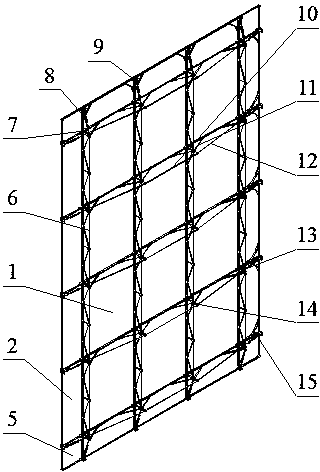

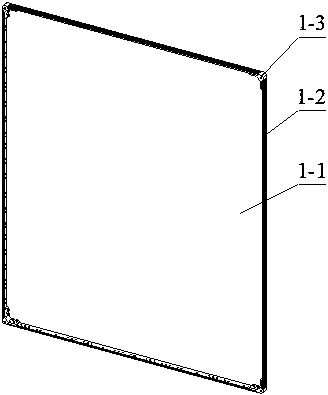

[0031] Such as Figure 1-6 Shown, a kind of large-span low electromagnetic loss planar membrane structure, it comprises membrane assembly, and described membrane assembly comprises middle membrane assembly 1, the edge membrane assembly 2 of edge portion and the corner membrane assembly 3 of corner portion, described The intermediate membrane assembly 1, the edge membrane assembly 2 and the corner membrane assembly 3 are all composed of a membrane material 1-1, a side bar 1-2, a corner connector 1-3 and a pressure film plate 1-4. The intermediate membrane After the membrane material 1-1 on the component 1, the edge membrane component 2 and the corner membrane component 3 is bent over 90 degrees around the edge rod 1-2, it is pressed and fixed by the pressure film plate 1-4 and the pressure film screw 1-5. In the groove on the side bar 1-2, the side bar 1-2 and the corner connector 1-3 are connected by bolts 1-6, and the adjacent middle membrane assembly 1, edge membrane assembl...

Embodiment 2

[0034] Such as Figure 1-6 Shown, a kind of large-span low electromagnetic loss planar membrane structure, it comprises membrane assembly, and described membrane assembly comprises middle membrane assembly 1, the edge membrane assembly 2 of edge portion and the corner membrane assembly 3 of corner portion, described The intermediate membrane assembly 1, the edge membrane assembly 2 and the corner membrane assembly 3 are all composed of a membrane material 1-1, a side bar 1-2, a corner connector 1-3 and a pressure film plate 1-4. The intermediate membrane After the membrane material 1-1 on the component 1, the edge membrane component 2 and the corner membrane component 3 is bent over 90 degrees around the edge rod 1-2, it is pressed and fixed by the pressure film plate 1-4 and the pressure film screw 1-5. In the groove on the side bar 1-2, the side bar 1-2 and the corner connector 1-3 are connected by bolts 1-6, and the adjacent middle membrane assembly 1, edge membrane assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com