Method for improving yield of vitamin B12 based on regulation of ammonia nitrogen index

A vitamin and B12 technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as premature aging of bacteria, and achieve the effect of promoting bacterial growth, increasing fermentation units, and high-density fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

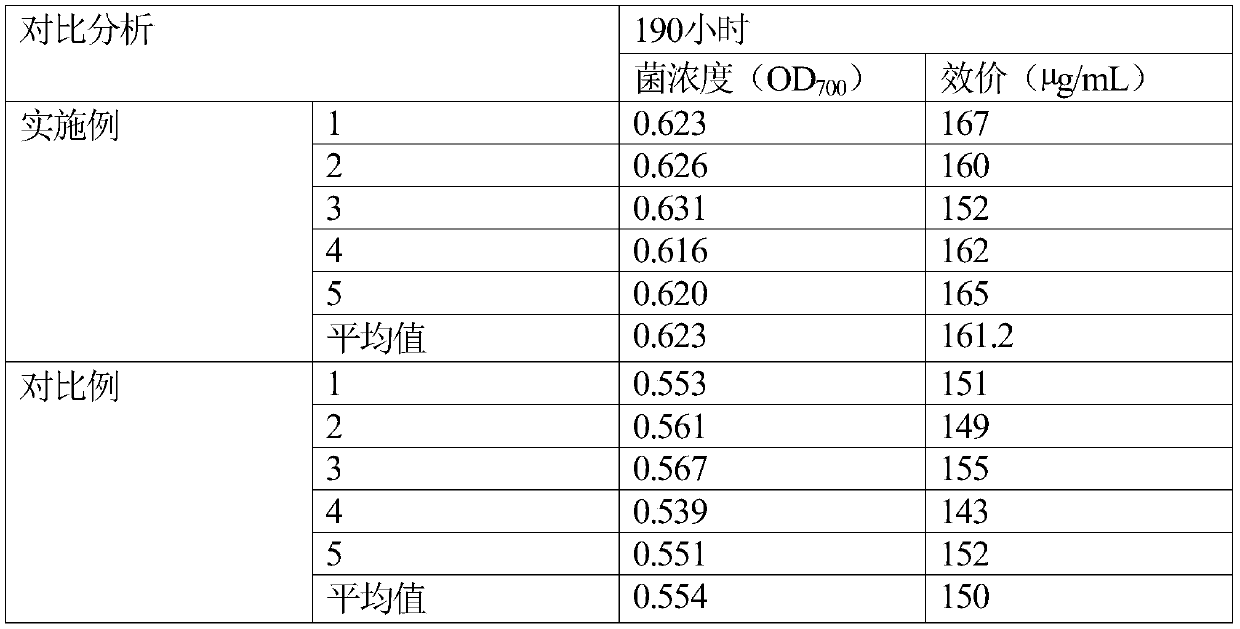

Examples

Embodiment 1

[0020] For the yeast extract juice addition experiment, the shake flask experiment was carried out:

[0021] Carry out seed culture in a 300mL shake flask, the filling volume is 50mL, and the seed medium is: maltose 53-55m with a concentration of 20%±2%. 3 / m 3 , corn syrup 25-27Kg / m 3 , betaine 3.7-3.9Kg / m 3 , magnesium oxide 300-320g / m 3 , Ammonium sulfate 920-940g / m 3 , diammonium hydrogen phosphate 2.4-2.6g / m 3 , cobalt chloride 25-27g / m 3 , precursor 7.6-7.8g / m 3 , zinc sulfate 24-26g / m 3 , calcium carbonate 3.0-3.2Kg / m 3 . The pH of the seed medium is 7.0, the temperature is 120°C-122°C, and the sterilization time is 30min. Insert 2mL of the bacterial suspension, and shake at 29°C and 250rpm until the optical density of the bacteria in the seed liquid (OD 700 ) reached more than 0.3, transplanted.

[0022] Carry out fermentation culture in a 300mL shake flask, the filling volume is 25mL, and the fermentation medium is 1.0-1.2m maltose with a concentration of 2...

Embodiment 2

[0027] at 5m 3 Add maltose 1.0-1.2m with a concentration of 20%±2% in the fermenter 3 / m 3 , corn syrup 0.05Kg / m 3 , Betaine 11-13Kg / m 3 , magnesium oxide 600-620g / m 3 , ammonium sulfate 1.1-1.3Kg / m 3 , diammonium hydrogen phosphate 600-620g / m 3 , cobalt chloride 90-92g / m 3 , precursor 65-67g / m 3 , zinc sulfate 24-26g / m 3 , urea 450-470g / m 3 , ferric chloride 0.6-0.7Kg / m 3 , calcium carbonate 1.1-1.3Kg / m 3 . Adjust the pH value of the fermentation medium to 7.00. After the batching is completed, steam sterilization is carried out. Sterilization conditions: pressure 0.10-0.13MPa, temperature 120°C-122°C, sterilization time 30min, after sterilization is completed, cool and pressurize with sterile air , awaiting transplantation.

[0028] The cultivated seed solution is transferred into the fermentation medium for cultivation, and the inoculation amount is controlled at 10%. Culture conditions: tank pressure 0.04-0.05MPa, tank temperature 30°C-33°C, air flow 15-20m ...

Embodiment 3

[0032] at 5m 3 Add maltose 1.0-1.2m with a concentration of 20%±2% in the fermenter 3 / m 3 , corn syrup 0.05Kg / m 3 , Betaine 11-13Kg / m 3 , magnesium oxide 600-620g / m 3 , ammonium sulfate 1.1-1.3Kg / m 3 , diammonium hydrogen phosphate 600-620g / m 3 , cobalt chloride 90-92g / m 3 , precursor 65-67g / m 3 , zinc sulfate 24-26g / m 3 , urea 450-470g / m 3 , ferric chloride 0.6-0.7Kg / m 3 , calcium carbonate 1.1-1.3Kg / m 3 . Adjust the pH value of the fermentation medium to 7.00. After the batching is completed, steam sterilization is carried out. Sterilization conditions: pressure 0.10-0.13MPa, temperature 120°C-122°C, sterilization time 30min, after sterilization is completed, cool and pressurize with sterile air , awaiting transplantation.

[0033] The cultivated seed solution is transferred into the fermentation medium for cultivation, and the inoculation amount is controlled at 10%. Culture conditions: tank pressure 0.04-0.05MPa, tank temperature 30°C-33°C, air flow 15-20m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com