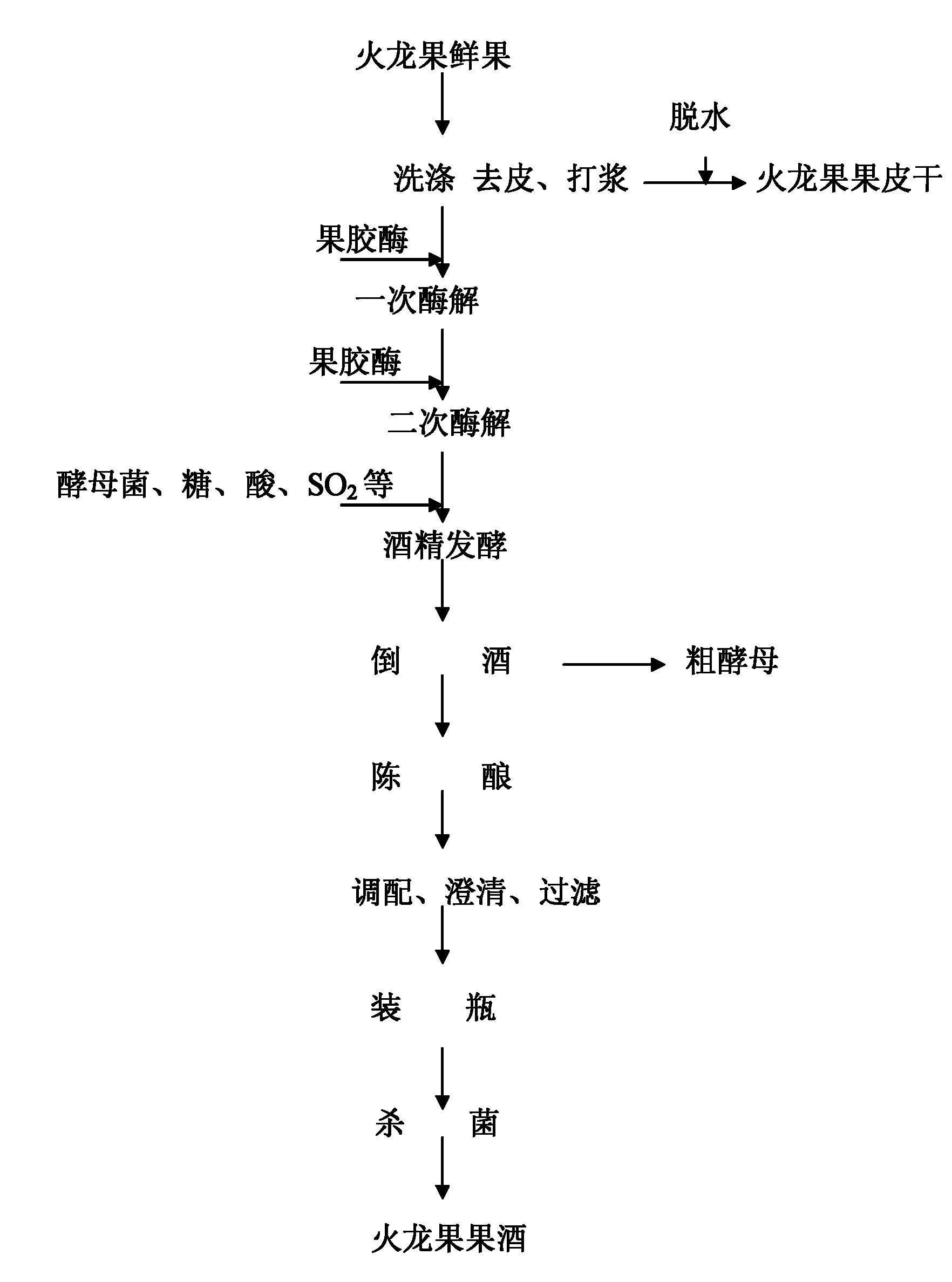

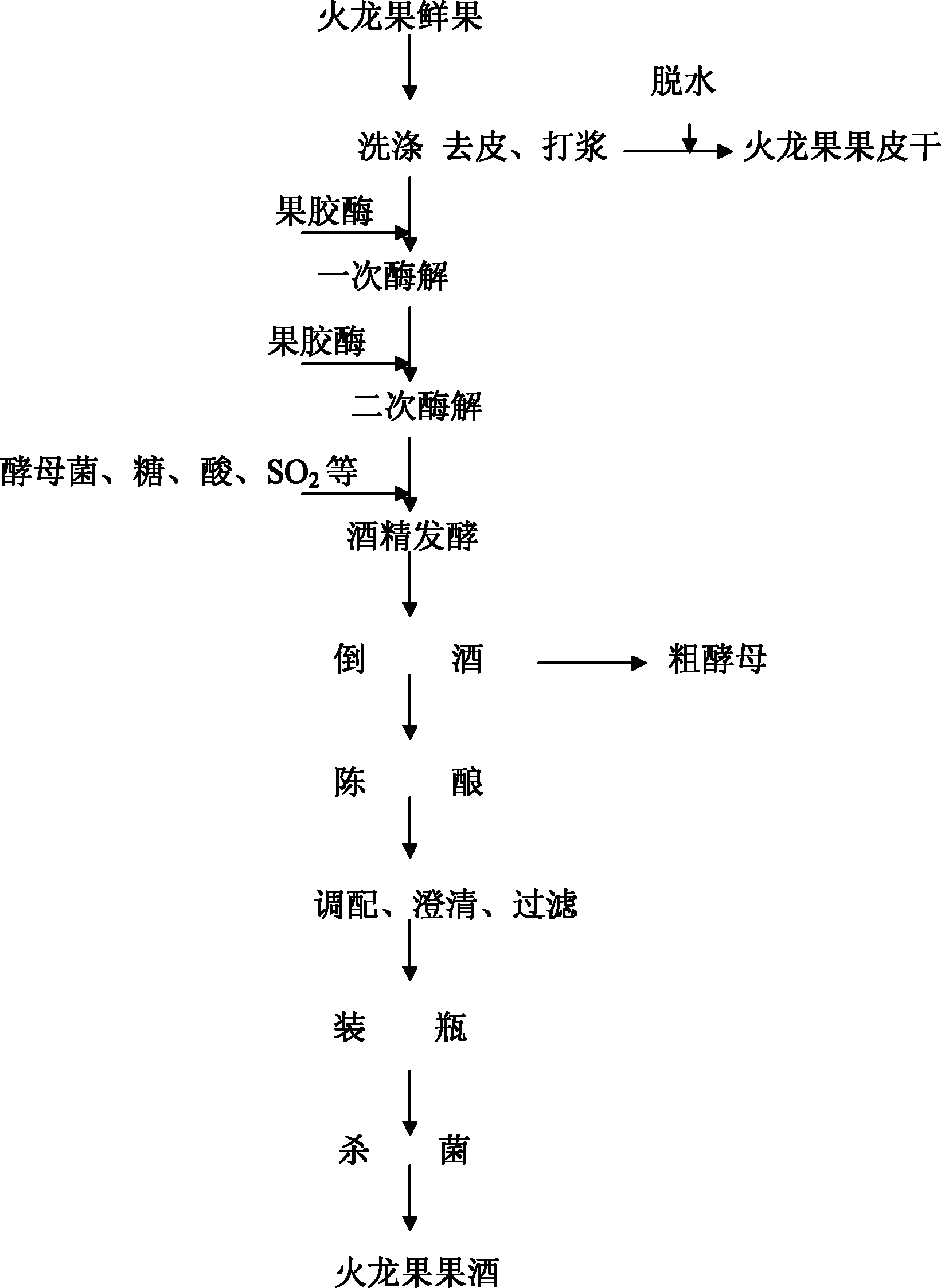

Residue-free production method of dragon fruit wine

A production method and technology for dragon fruit wine, applied in the field of fruit wine brewing, can solve the problems of difficult alcoholic fermentation, difficult utilization of pomace, waste of raw materials, etc., and achieve the effects of unique taste, improved resource utilization, and clear and transparent wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, carry out according to the following steps:

[0023] Select 100kg of ripe fresh white flesh dragon fruit raw material, wash it with water, peel it with a stainless steel knife, put the pulp into a crusher to make dragon fruit pulp; add 10g of pectinase, stir well and place it at room temperature for 0.5h; After collecting the clear and transparent dragon fruit juice on the upper layer, add 10g of pectinase (Pectinex XXL type pectinase from Novozymes) to the remaining pulp, and after stirring, enzymolyze it at room temperature until there is no pulp ( about 0.5h); combine the two enzymatic hydrolysis solutions, and pass through SO with a concentration of 60mg / L 2 Stir evenly, then add sucrose to adjust to fruit juice soluble solids concentration of 18g / 100g, add citric acid to adjust the pH value of fruit juice to 3.0, add 3ml / 100ml vigorously growing fruit wine wine mother (wine high activity produced by Angel Yeast Co., Ltd. Dried yeast is obtained by ge...

Embodiment 2

[0025] Embodiment 2, carry out according to the following steps:

[0026] Select 100kg of ripe fresh red pitaya raw materials, wash them with water, peel them with a stainless steel knife, put the pulp into a crusher to make pitaya pulp; add 200g of pectinase, stir well and place it at room temperature for 2 hours; collect After clear and transparent dragon fruit juice on the upper layer, add 200g of pectinase (Pectinex XXL from Novozymes) to the remaining pulp, and after stirring, enzymolyze at room temperature until there is no pulp (about 2 hours); Combine the two enzymatic hydrolysis solutions, add the equivalent concentration of 60mg / L SO 2 sodium bisulfite, stir evenly, then add sucrose to adjust the concentration of soluble solids in the fruit juice to 25g / 100g, add citric acid to adjust the pH value of the fruit juice to 4.0, add 5ml / 100ml vigorously growing fruit wine and wine to carry out alcoholic fermentation, and ferment to the degree of alcohol Stop fermentation...

Embodiment 3

[0028] Embodiment 3, carry out according to the following steps:

[0029] Select 100kg of ripe fresh yellow-fleshed dragon fruit raw materials, wash with water, peel the skin with a stainless steel knife, put the pulp into a crusher to make dragon fruit pulp; add 100g of pectinase, stir well and place it at room temperature for 1 hour; collect After clear and transparent dragon fruit juice on the upper layer, add 100g of pectinase (Pectinex XXL from Novozymes) to the remaining fruit pulp, and after stirring, enzymolyze at room temperature until there is no fruit pulp (about 1h); Combine the two enzymatic hydrolysis solutions, and pass through SO with a concentration of 200mg / L 2 Stir evenly, then add sucrose to adjust to fruit juice soluble solids concentration 22g / 100g, add citric acid to adjust the pH value of fruit juice to 3.5, add 4ml / 100ml vigorously growing fruit wine wine mother (wine high activity dry wine produced by Angel Yeast Co., Ltd. The yeast is obtained by kn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com