Method for extracting latex from pole-strength electric field

A strong electric field and latex technology, applied in the field of latex extraction with extremely strong electric field, can solve the problems of intensified corrosion of positive electrode materials, non-negligible electrolysis, and high acidification rate, and achieve the effect of reducing the use of flocculants, superior performance and complete retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Pass 1000g of concentrated natural rubber latex with a mass content of 60% of the dry glue into the extraction device with an extremely strong electric field from one side of the glue inlet. The pole distance between the two rollers is 0.3mm, the electric field strength is 1500000V / m, and the ratio of the strongest electric field strength to the weakest electric field strength is 50. The latex was extracted by an extremely strong electric field to obtain clarified liquid and rubber flakes. The latex was extracted until the residual rubber in the clarified liquid was less than or equal to 0.06g, dried in cold air and packaged to obtain 599.94g of finished rubber.

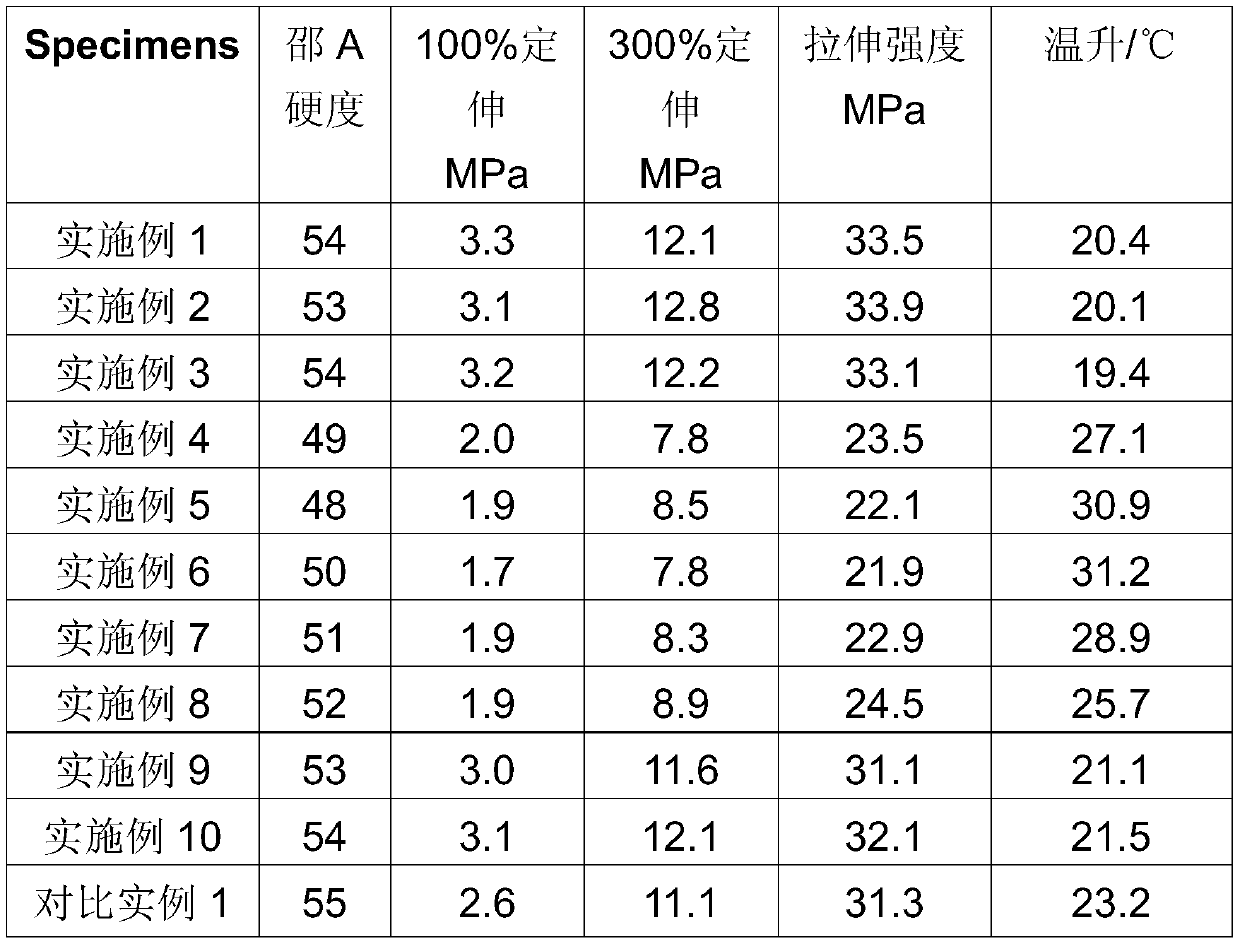

[0037] Take 100g of the above solid rubber, 5g of ZnO, 2g of stearic acid, 1g of anti-aging agent 1010NA, 30g of N330, 1.2g of accelerator CZ, 2g of sulfur, mix the rubber, measure the vulcanization curve and rubber processing performance after parking for 8 hours, vulcanize at 150°C, Measuring mechanical prope...

Embodiment 2

[0039] Pass 1000g of natural rubber latex with a dry glue mass content of 30% from one side of the glue inlet into the extraction device with an extremely strong electric field. The device is a two-conductive plate type device with an extremely strong electric field. Adjust the DC voltage 9V and adjust the two poles of the extremely strong electric field plate, so that the distance between one end of the negative electrode and the positive electrode is 0.3mm, the electric field strength is 30000V / m, and the ratio of the strongest electric field strength to the weakest electric field strength is 30. The latex was extracted by an extremely strong electric field to obtain clarified liquid and rubber flakes. The latex was extracted until the residual rubber in the clarified liquid was 0.03 g, dried with hot air, and packaged to obtain 249.97 g of finished rubber.

[0040] Take 100g of the above solid rubber, 5g of ZnO, 2g of stearic acid, 1g of anti-aging agent 1010NA, 30g of N330,...

Embodiment 3

[0042] Pass 3000g of latex rubber with a dry glue mass content of 5% into the extraction device with a very strong electric field from one side of the glue inlet. The distance between the two pole plates is 0.5mm, the electric field strength is 200000V / m, and the ratio of the strongest electric field strength to the weakest electric field strength is 20. The latex was extracted by an extremely strong electric field to obtain clarified liquid and rubber flakes. The latex was extracted until the residual rubber in the clarified liquid was 0.015 g. After washing, infrared drying, and packaging, 149.985 g of finished rubber was obtained.

[0043] Take 100g of the above solid rubber, 5g of ZnO, 2g of stearic acid, 1g of anti-aging agent 1010NA, 30g of N330, 1.2g of accelerator CZ, 2g of sulfur, mix the rubber, measure the vulcanization curve and rubber processing performance after parking for 8 hours, vulcanize at 150°C, Measuring mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com