ZnO nanobelt and preparation method thereof

A nanobelt and glass substrate technology, applied in the field of nanomaterials, can solve the problems of long hydrothermal growth cycle and complex formula of zinc oxide nanosheets, and achieve good application prospects, mature preparation equipment, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for ZnO nanobelts, comprising the following steps:

[0027] S1), cleaning the glass substrate, using ethanol and deionized water to ultrasonically clean the glass for 3 times, and drying it with an air gun;

[0028] S2), the preparation of the precursor thin film, transfer the cleaned glass substrate to the high vacuum coating equipment, and evenly place the ZnO powder with a purity of more than 99.9% on the tungsten boat, and then pump the air pressure to less than 5×10 -3 Pa; then slowly increase the evaporation current to 140A within 10 minutes, and evaporate for 10 minutes to obtain an amorphous ZnO precursor film on the glass substrate;

[0029] S3), high-temperature annealing, transfer the prepared precursor film to an annealing furnace, raise the temperature to 600°C at a rate of 10°C / min, and keep it warm for 60 minutes to obtain uniformly distributed ZnO nanobelts on the glass.

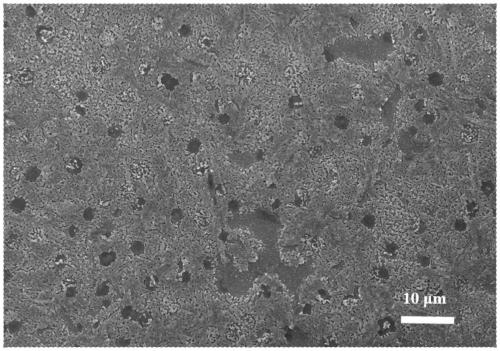

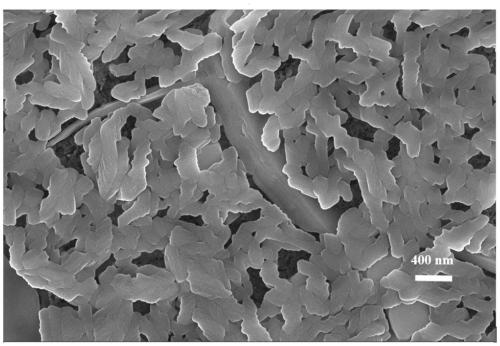

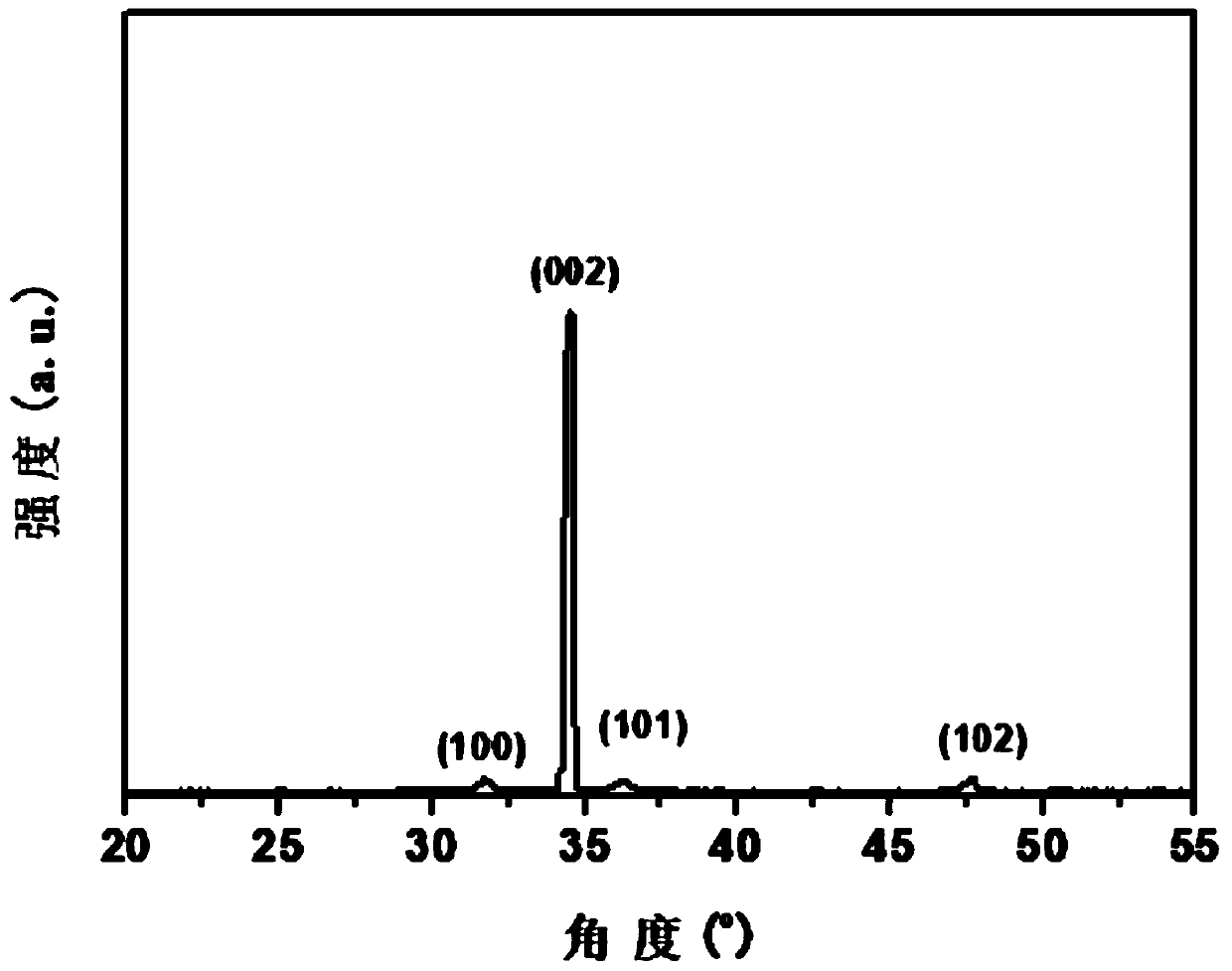

[0030] figure 1 with figure 2 Low power and high power sc...

Embodiment 2

[0034] A preparation method for ZnO nanobelts, comprising the following steps:

[0035] S1), cleaning the glass substrate, using ethanol and deionized water to ultrasonically clean the glass for 4 times, and drying it with an air gun;

[0036] S2), the preparation of the precursor thin film, transfer the cleaned glass substrate to the high vacuum coating equipment, and evenly place the ZnO powder with a purity of more than 99.9% on the tungsten boat, and then pump the air pressure to less than 5×10 -3 Pa; then slowly increase the evaporation current to 100A within 8 minutes, and evaporate for 20 minutes to obtain an amorphous ZnO precursor film on the glass substrate;

[0037] S3), high-temperature annealing, transfer the prepared precursor film to an annealing furnace, raise the temperature to 500°C at a rate of 4°C / min, and keep it for 120 minutes to obtain uniformly distributed ZnO nanobelts on the glass.

Embodiment 3

[0039] A preparation method for ZnO nanobelts, comprising the following steps:

[0040] S1), cleaning the glass substrate, using ethanol and deionized water to ultrasonically clean the glass for 5 times, and drying it with an air gun;

[0041] S2), the preparation of the precursor thin film, transfer the cleaned glass substrate to the high vacuum coating equipment, and evenly place the ZnO powder with a purity of more than 99.9% on the tungsten boat, and then pump the air pressure to less than 5×10 -3 Pa; then slowly increase the evaporation current to 120A within 6 minutes, and evaporate for 15 minutes to obtain an amorphous ZnO precursor film on the glass substrate;

[0042] S3), high-temperature annealing, transfer the prepared precursor film to an annealing furnace, raise the temperature to 550°C at a rate of 7°C / min, and keep it for 100 minutes to obtain uniformly distributed ZnO nanobelts on the glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com