A method for improving the hardness of spherical calcium chloride produced by acid calcium method

A technology of calcium chloride and calcium acid, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of prolonged production cycle, rising production cost and equipment repair cost, etc. The effect of forming rate, reducing product cost and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical process of the present invention will be further described in detail in conjunction with specific applications below.

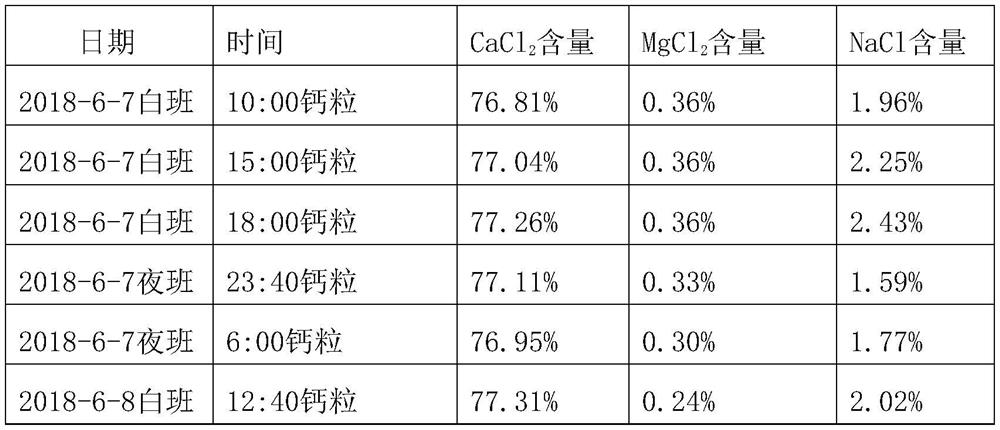

[0014] In the process of producing spherical calcium chloride in the existing conventional technology, it includes hydrochloric acid and limestone reacting to generate calcium chloride solution, namely calcium acid reaction process of calcium water, two-effect evaporation process, dust removal process, evaporation calcium production process and feeding into fluidized bed In the granulation process of forming spherical calcium chloride, the hardness and density of calcium chloride particles with higher purity are not high, and they are easy to pulverize, resulting in a low granulation rate of spherical calcium chloride in the final product. The first test and the actual verification of on-site production show that when more than 1.9% sodium chloride is added to the spherical calcium chloride, the hardness of the spherical calcium chloride p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com