Aluminum foil winding device

A winding device, aluminum foil technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve problems such as aluminum foil roll breakage

Inactive Publication Date: 2019-09-06

六安堰山自动化设备销售有限公司

View PDF14 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the problem in the prior art that the aluminum foil roll needs to be rewound or discarded after it is broken, the purpose of the present invention is to provide an aluminum foil winding device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

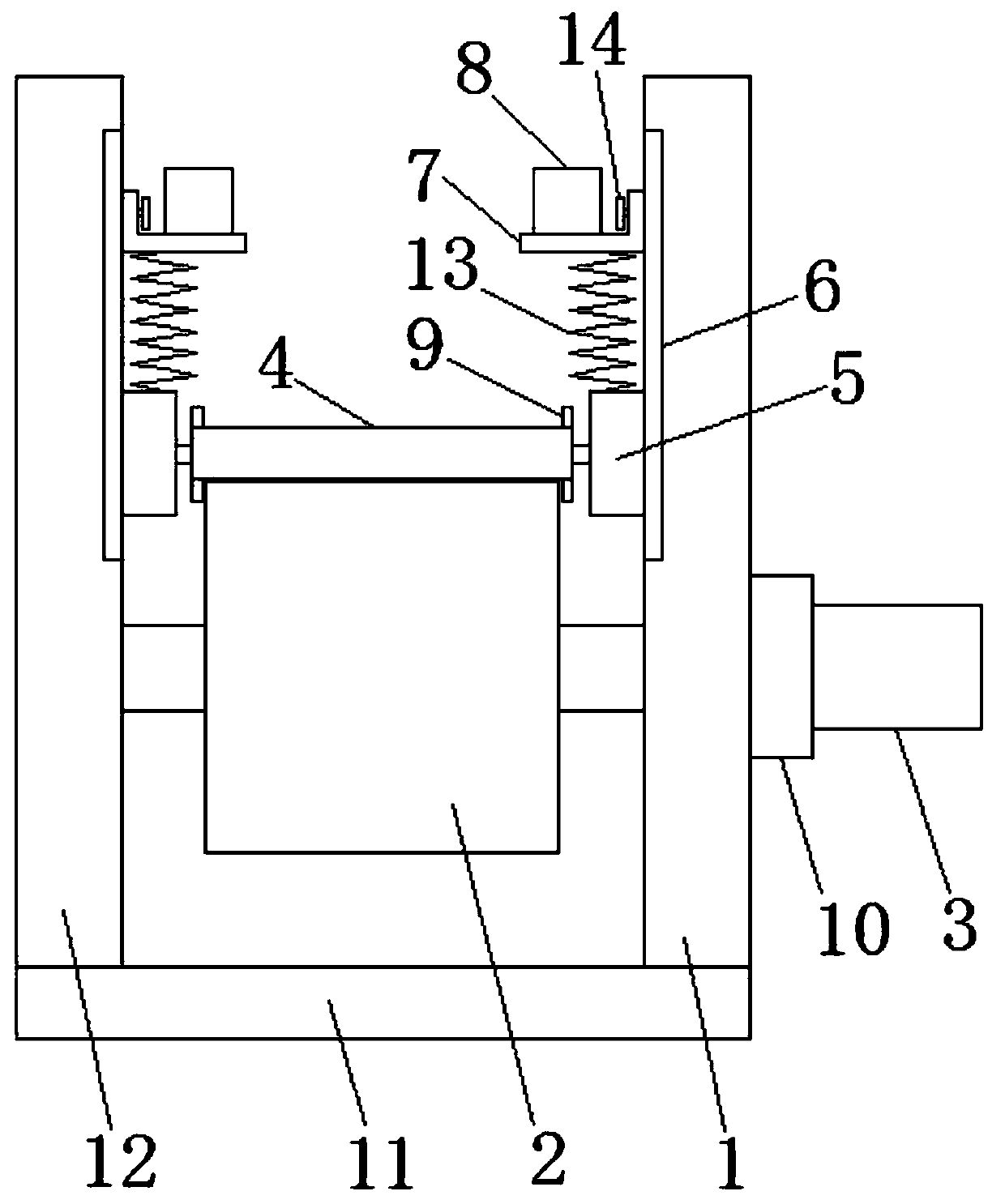

[0023] The difference from the first embodiment is that in this embodiment, the sliding table 7 is provided with locking screws 14 for locking the sliding table 7 on the frame 1 . The setting of the locking screw 14 makes the counterweight 8 on the slide table 7 not transmit its gravity to the pressure roller 4 when needed, but only relies on the dead weight of the pressure roller 4 or its spring 13 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an aluminum foil winding device, and belongs to the field of aluminum foil processing. The aluminum foil winding device comprises a rack, a winding drum rotationally connectedto the rack, and a winding motor fixedly arranged on the rack; the winding motor is connected with the winding drum through a torsion limiter; a compression roller is arranged above the winding drum,the compression roller is rotationally connected to a sliding seat, and a sliding rail matched with the sliding seat is arranged on the rack; a sliding table is installed on the portion, above the sliding seat, of the sliding rail, and a balancing weight is arranged on the sliding table; and a spring is connected between the sliding table and the sliding seat. According to the aluminum foil winding device, aluminum foil can be prevented from being broken due to overlarge winding tension, the phenomenon that the aluminum foil is loosened due to breakage caused by other factors can be avoided, and the aluminum foil is prevented from being re-wound and even scrapped.

Description

technical field [0001] The invention relates to the field of aluminum foil processing equipment, in particular to an aluminum foil winding device. Background technique [0002] In the rolling production process of aluminum foil, the aluminum foil needs to be wound on a reel. During the winding process, if the winding tension is too large, or if there are too many flaws in the aluminum foil and cracks appear, the aluminum foil roll may break. At this time, the aluminum foil on the winding drum will appear loose, ranging from It is made up by rewinding, and the whole roll of aluminum foil is scrapped. Contents of the invention [0003] Aiming at the problem in the prior art that an aluminum foil roll needs to be rewound or scrapped due to breakage, the purpose of the present invention is to provide an aluminum foil winding device. [0004] To achieve the above object, the technical solution of the present invention is: [0005] An aluminum foil winding device, comprising ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H18/10B65H18/26B65H23/195

CPCB65H18/10B65H18/26B65H23/1955B65H2701/1133B65H2701/1732

Inventor 李少杰蒋克项

Owner 六安堰山自动化设备销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com