Adjustable support

A friction wheel and stud technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of inconvenient adjustment of gears, limited adjustability of brackets, and small practical range, and can extend the range of use and use. Wide and directional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

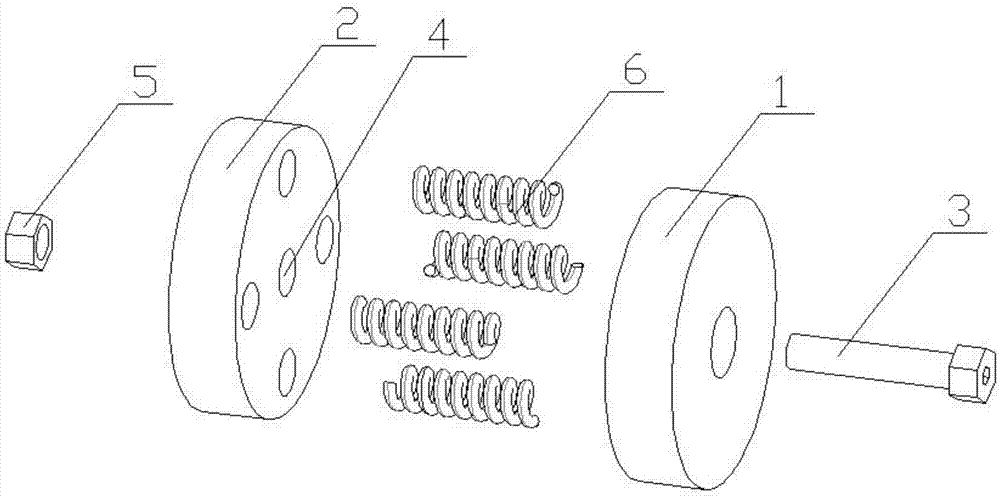

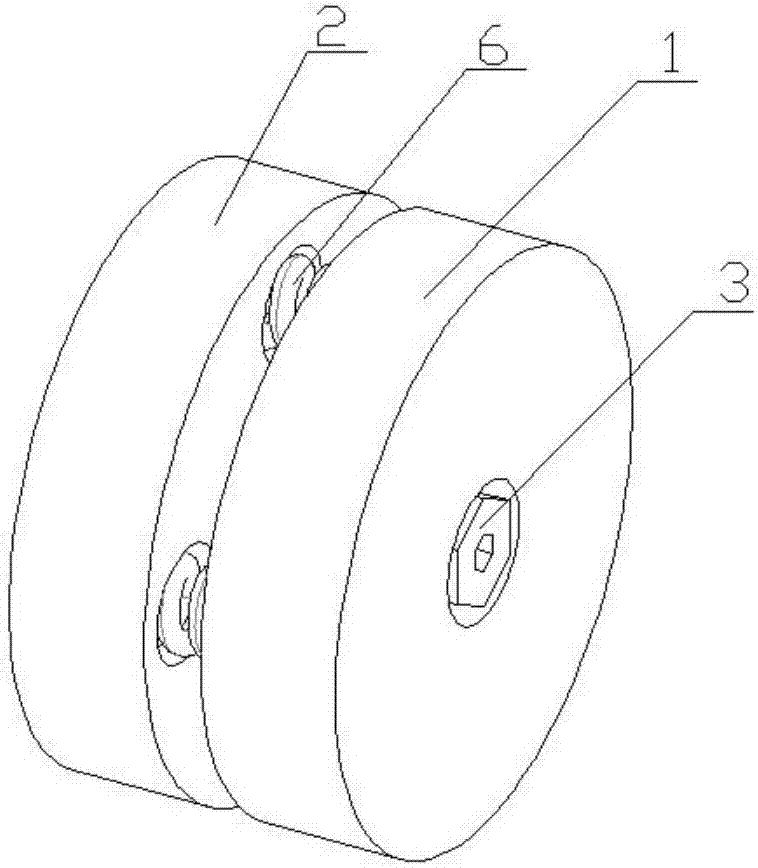

[0028] An adjustable bracket includes a first friction wheel 1 and a second friction wheel 2, a stud 3 is provided at the center of the first friction wheel 1, and a stud 3 is provided at the center of the second friction wheel 2, which is connected to the screw. The through hole 4 matched with the column 3, the screw end of the stud 3 passes through the through hole 4 and adjusts the distance between the first friction wheel 1 and the second friction wheel 2 through the nut 5, the first friction wheel Four springs 6 are evenly distributed around the stud 3 between the top 1 and the second friction wheel 2; the stud 3 is a bolt structure.

Embodiment 2

[0030] An adjustable bracket, the only difference from Embodiment 1 is: the two ends of the spring 6 are provided with threaded discs, and the surface between the first friction wheel 1 and the second friction wheel 2 is provided with the thread The threaded hole matched with the plate is convenient for the disassembly and installation of the spring 6, and improves the scope of use of the adjustable bracket.

Embodiment 3

[0032] An adjustable bracket, the only difference from Embodiment 1 is: the two ends of the spring 6 are provided with connectors, the ends of the connectors are provided with bosses, the first friction wheel 1, the second friction wheel The surface between 2 is provided with the groove that cooperates with described boss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com