Airflow-assisted device for improving the quality of EDM composite perforation

A technology of processing quality and EDM, which is applied in the field of devices to improve the processing quality of EDM-electrolysis composite perforation, can solve problems such as large taper, processing stray corrosion, and poor precision of small holes, so as to inhibit electrolytic reaction and reduce small holes Taper, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

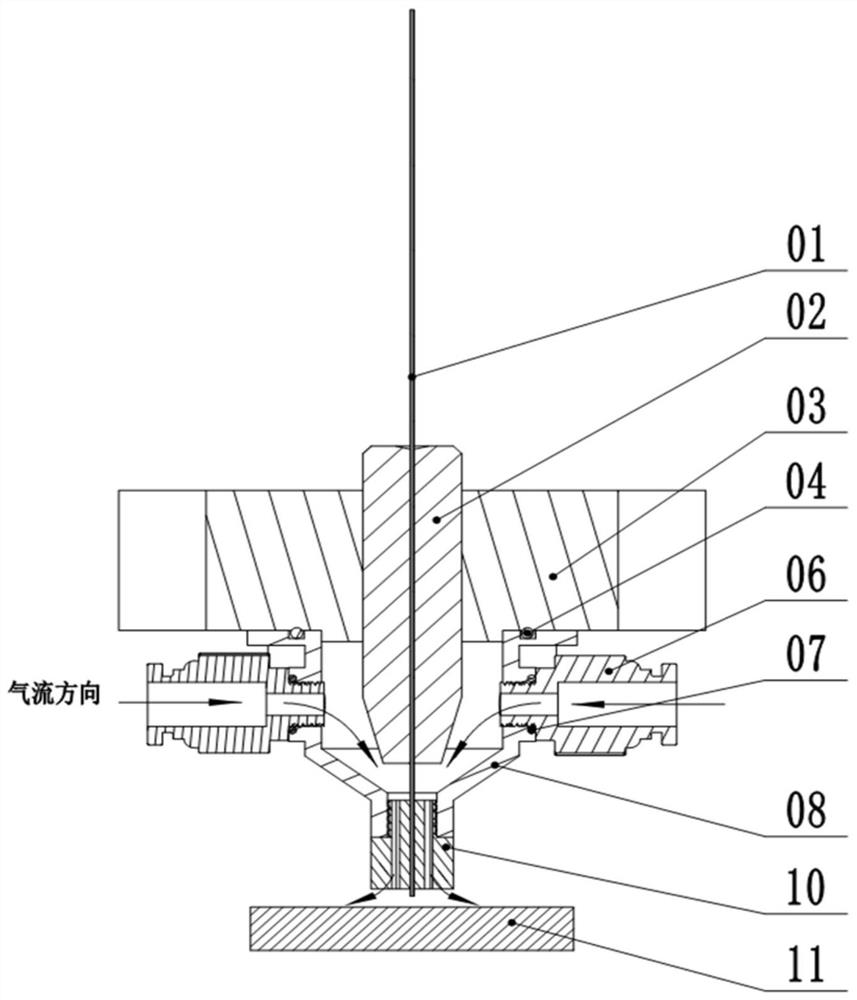

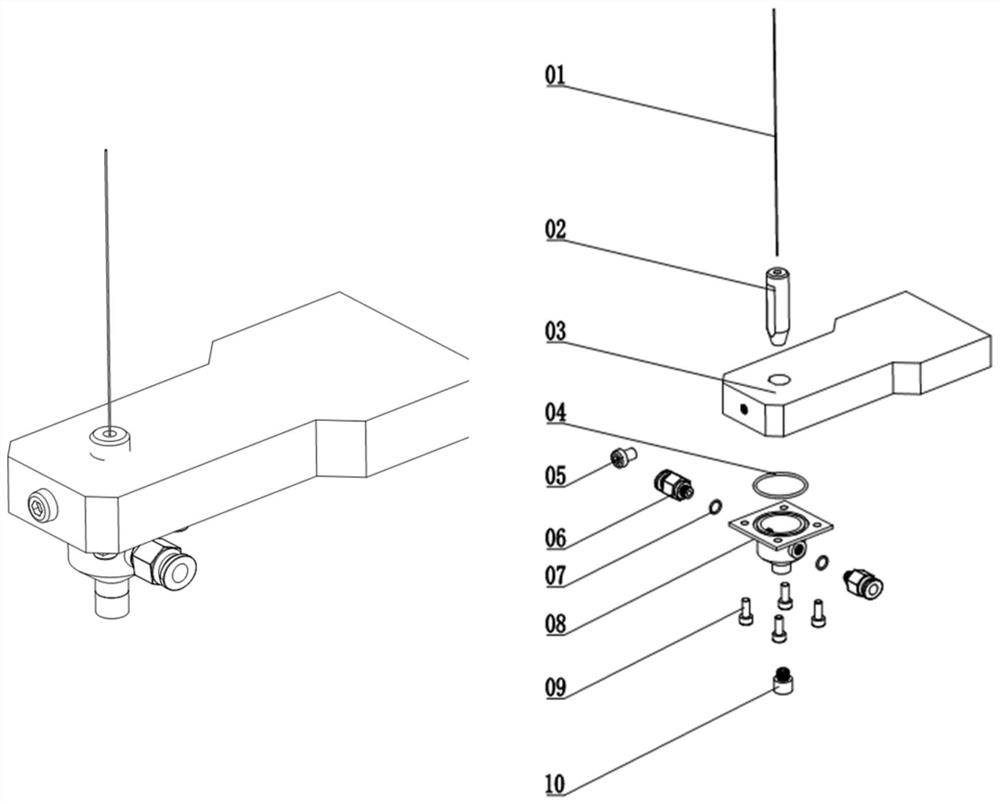

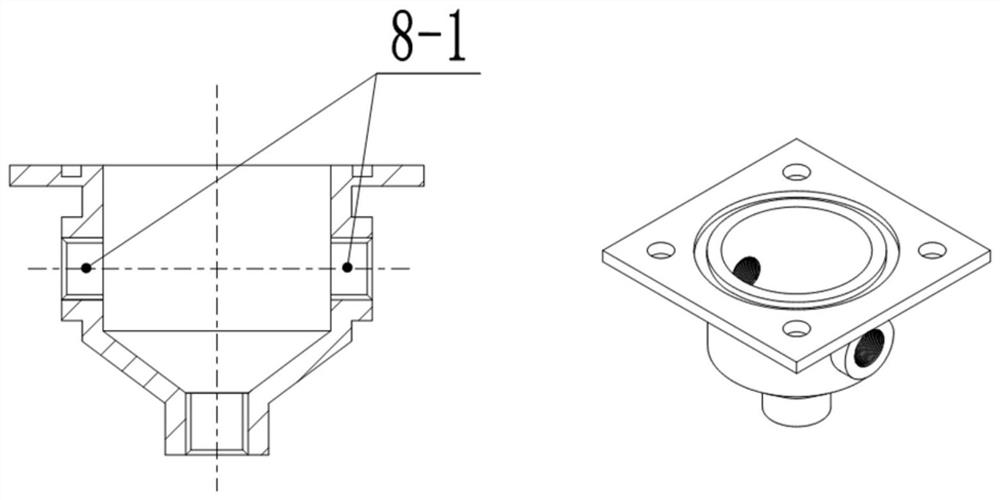

[0039] figure 1 Shown is a schematic diagram of the device for improving the quality of EDM-electrolytic perforation with airflow assistance of the present invention. The overall device includes a tube electrode 01, a guide 02, a machine tool slider 03, a sealing ring 04, a set screw 05, an air inlet plug 06, an automatic Tap the screw 07, the intake shell 08 and the flow divider 10. Among them: special-shaped holes are processed on the slide block of the machine tool, and the guide is installed in the special-shaped holes and fixed by set screws. The air intake shell and sealing ring are installed under the machine slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com