Cationic surfactant and preparation method thereof

A surfactant and cation technology, applied in the field of preparation of indole quaternary ammonium salts, can solve the problems of reducing foam, biodegradability and poor water solubility of surfactant systems, and achieve good emulsification, simple steps and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

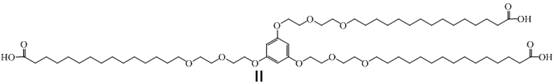

[0030] Synthesis of Indole Quaternary Ammonium Salt of Monodisperse Pentadecyl Three-Armed Polyethylene Glycol Ether

[0031] The synthesis process contains three steps: (1) Synthesis of three-arm dodecapolyethylene glycol p-toluenesulfonate 2) Synthesis of pentadecanoic acid three-arm dodecapolyethylene glycol; (3) Pentadecyl three Synthesis of Indole Quaternary Ammonium Salts of Armed Polyethylene Glycol Ethers.

[0032] (1) Synthesis of three-arm polyethylene glycol p-toluenesulfonate

[0033] 0 o Under C, in the dichloromethane (30ml) solution of three-arm dodecapolyethylene glycol (3mmol) and triethylamine (3mmol), slowly drop p-toluenesulfonyl chloride (10mmol), continue stirring at normal temperature for 12 Hour. The reaction was quenched by saturated sodium bicarbonate (100mL), then separated, and after the organic phase was concentrated under reduced pressure, the crude product was directly put into the next reaction.

[0034] (2) Synthesis of pentadecanoic acid t...

Embodiment 2

[0039] Synthesis of Indole Quaternary Ammonium Salt of Monodisperse Pentadecyl Three-Armed Tetracospolyethylene Glycol Ether

[0040] The synthetic process contains three steps: (1) synthesis of three-arm tetracos-polyethylene glycol to DMF sulfonate 2) synthesis of pentadecanoic acid three-arm tetracos-polyethylene glycol; (3) pentadecane Synthesis of indole quaternary ammonium salts of three-arm tetracospolyethylene glycol ethers.

[0041] (1) Synthesis of three-arm tetracos-polyethylene glycol p-toluenesulfonate

[0042] 0 o C, slowly add p-DMFsulfonyl chloride (10mmol) dropwise to the dichloromethane (30ml) solution of three-arm tetractracoethylene glycol (3mmol) and triethylamine (3mmol), and continue stirring at room temperature after the dropwise addition 12 hours. The reaction was quenched by saturated sodium bicarbonate (100mL), then separated, and after the organic phase was concentrated under reduced pressure, the crude product was directly put into the next reac...

Embodiment 3

[0048] Synthesis of Indole Quaternary Ammonium Salt of Monodisperse Pentadecyl Three-Armed Fourty-Octacopolyethylene Glycol Ether

[0049] The synthesis process contains three steps: (1) synthesis of three-arm forty-octacopolyethylene glycol to DMF sulfonate 2) synthesis of pentadecanoic acid three-arm forty-octacopolyethylene glycol; (3) pentadecyl three-arm forty-eight Synthesis of indole quaternary ammonium salts of polyethylene glycol ethers.

[0050] (1) Synthesis of three-arm forty-octacopolyethylene glycol p-toluenesulfonate

[0051] 0 oC, slowly drop p-toluenesulfonyl chloride (10mmol) in the dichloromethane (30ml) solution of three-arm 48 polyethylene glycol (3mmol) and triethylamine (3mmol), continue to stir at room temperature for 12 hours after the dropwise addition . The reaction was quenched by saturated sodium bicarbonate (100mL), then separated, and after the organic phase was concentrated under reduced pressure, the crude product was directly put into the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com