Calcium phosphate cement containing decalcified bone matrix, and preparation method and applications thereof

A technology of calcium phosphate bone cement and decalcified bone matrix, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve problems such as limited supply, need for secondary surgery, immune rejection, etc., and achieve good osteogenesis, Meet clinical needs and improve the effect of degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A calcium phosphate bone cement containing demineralized bone matrix (DBM), prepared by the following method:

[0027] (1) Weigh 64g of citric acid and 1.5g of sodium alginate, add the above two raw materials into 10ml of deionized water, dissolve to obtain a liquid phase, and store at room temperature for later use;

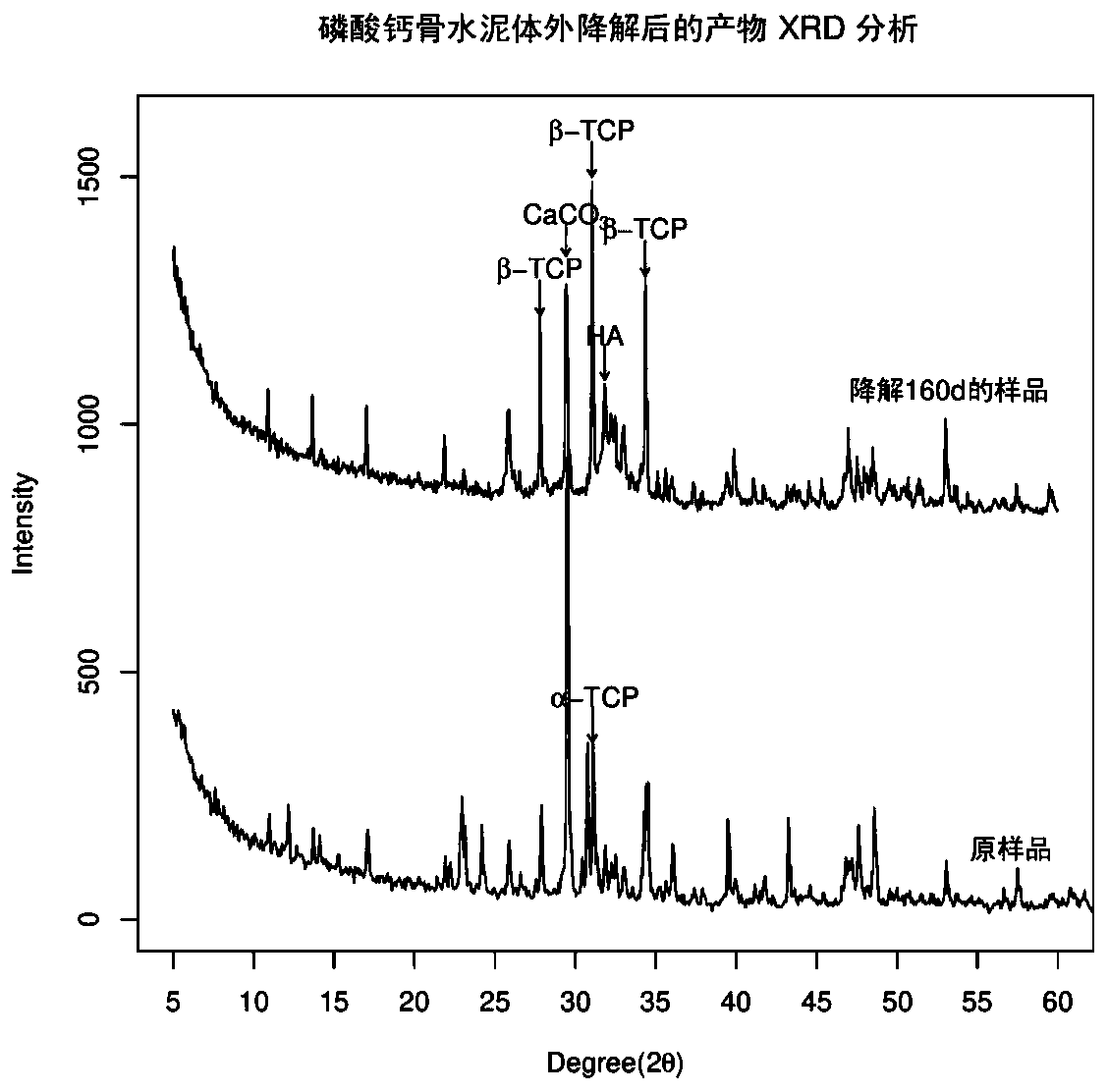

[0028] (2) Micron spherical heavy calcium carbonate, α-tricalcium phosphate (α-TCP), β-tricalcium phosphate (β-TCP), anhydrous calcium hydrogen phosphate (DCPA), hydroxyapatite (HA ), and micron flake DBM in a small mortar according to the mass ratio of 3:3:3:3:1:0.1, and then accurately measure the liquid phase according to the solid-liquid ratio of 1:0.4, and add the liquid phase to The solid phase powder was mixed quickly and evenly, and then filled into a mold with a length, width, and height of 1 cm, and solidified under the conditions of 37 ° C and 95% humidity to obtain a calcium phosphate bone cement containing DBM.

Embodiment 2

[0030] A calcium phosphate bone cement containing demineralized bone matrix (DBM), prepared by the following method:

[0031] (1) Weigh 64g citric acid, 1.5g chitosan, add above-mentioned two kinds of raw materials into 10ml deionized water, dissolve, obtain liquid phase, store at room temperature for subsequent use;

[0032] (2) Micron spherical heavy calcium carbonate, α-tricalcium phosphate (α-TCP), β-tricalcium phosphate (β-TCP), anhydrous calcium hydrogen phosphate (DCPA), hydroxyapatite (HA ), and micron-scale flake DBM in a small mortar according to the mass ratio of 3:3:3:3:1:0.5, and then accurately measure the liquid phase according to the solid-liquid ratio of 1:0.5, and add the liquid phase to the solid The phase powder was mixed quickly and evenly, and then filled into a mold with a length, width and height of 1 cm, and solidified under the conditions of 37 ° C and 95% humidity to obtain calcium phosphate bone cement containing DBM.

Embodiment 3

[0034] A calcium phosphate bone cement containing demineralized bone matrix (DBM), prepared by the following method:

[0035] (1) Weigh 32g citric acid, 2.0g chitosan, add above-mentioned two kinds of raw materials into 10ml deionized water, dissolve, obtain liquid phase, store for subsequent use at room temperature;

[0036] (2) Micron spherical light calcium carbonate, α-tricalcium phosphate (α-TCP), β-tricalcium phosphate (β-TCP), anhydrous calcium hydrogen phosphate (DCPA), hydroxyapatite (HA ), and millimeter-scale flake DBM in a small mortar according to the mass ratio of 3:3:3:3:1:2.0, and then accurately measure the liquid phase according to the solid-liquid ratio of 1:0.6, and add the liquid phase to the solid The phase powder was mixed quickly and evenly, and then filled into a mold with a length, width and height of 1 cm, and solidified under the conditions of 37 ° C and 95% humidity to obtain calcium phosphate bone cement containing DBM.

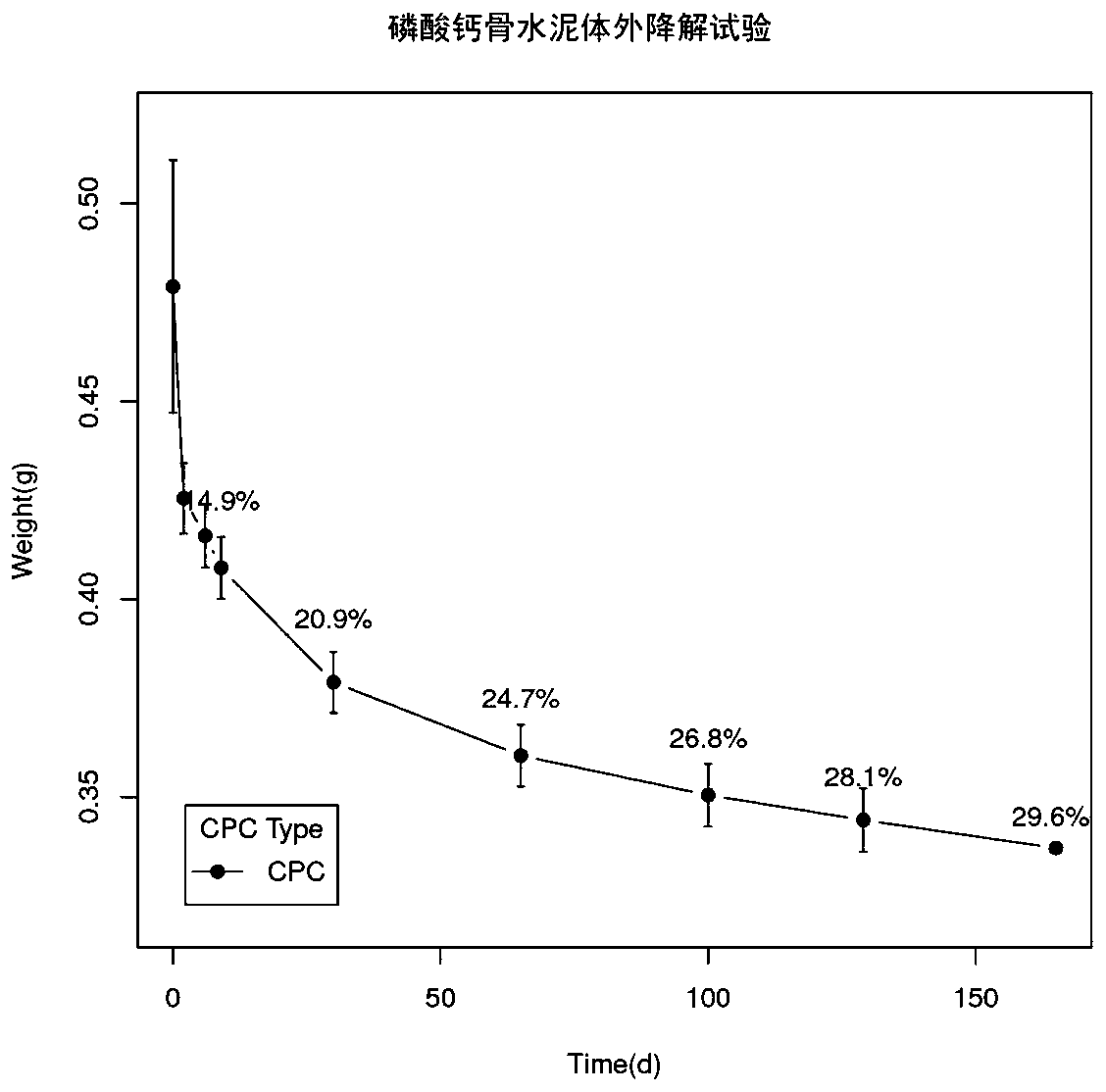

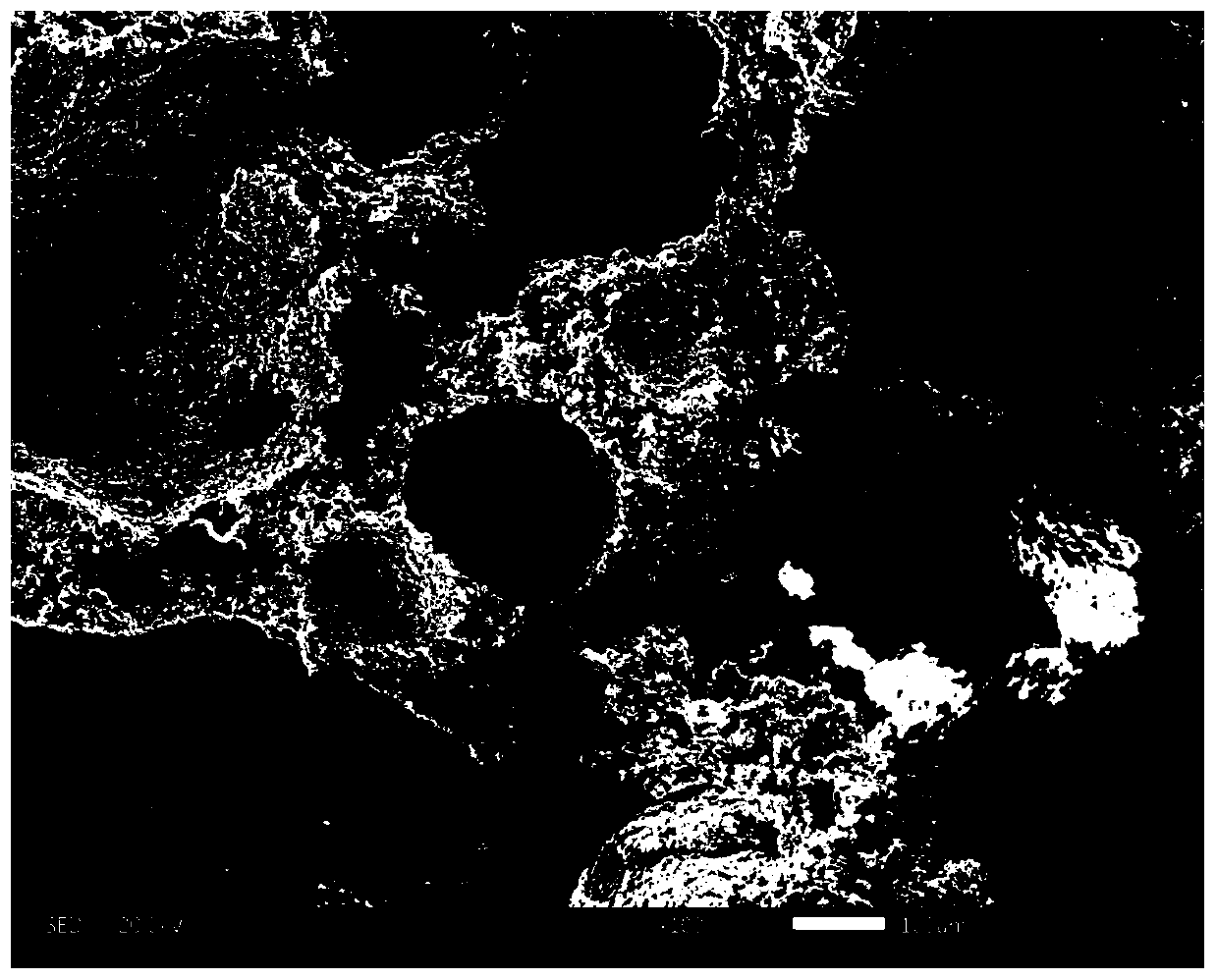

[0037] The obtained DBM-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com