Composite herbicide

A compound herbicide, a certain amount of technology, applied in the direction of herbicides, algicides, biocides, biocides, etc., can solve the problems of unavoidable direct contact, human health damage, etc., and achieve low degradation efficiency and accelerated degradation , the effect of rapid weeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The specific preparation process of the degradable polymer is as follows: Weigh 3.02kg of trimethylolpropane triglycidyl ether into 30mL of acetone, stir and mix evenly, add 1.47kg of glutamic acid to it, heat up to 50-60°C and stir to react 2-3h, and then filtered, washed and dried to obtain a degradable polymer.

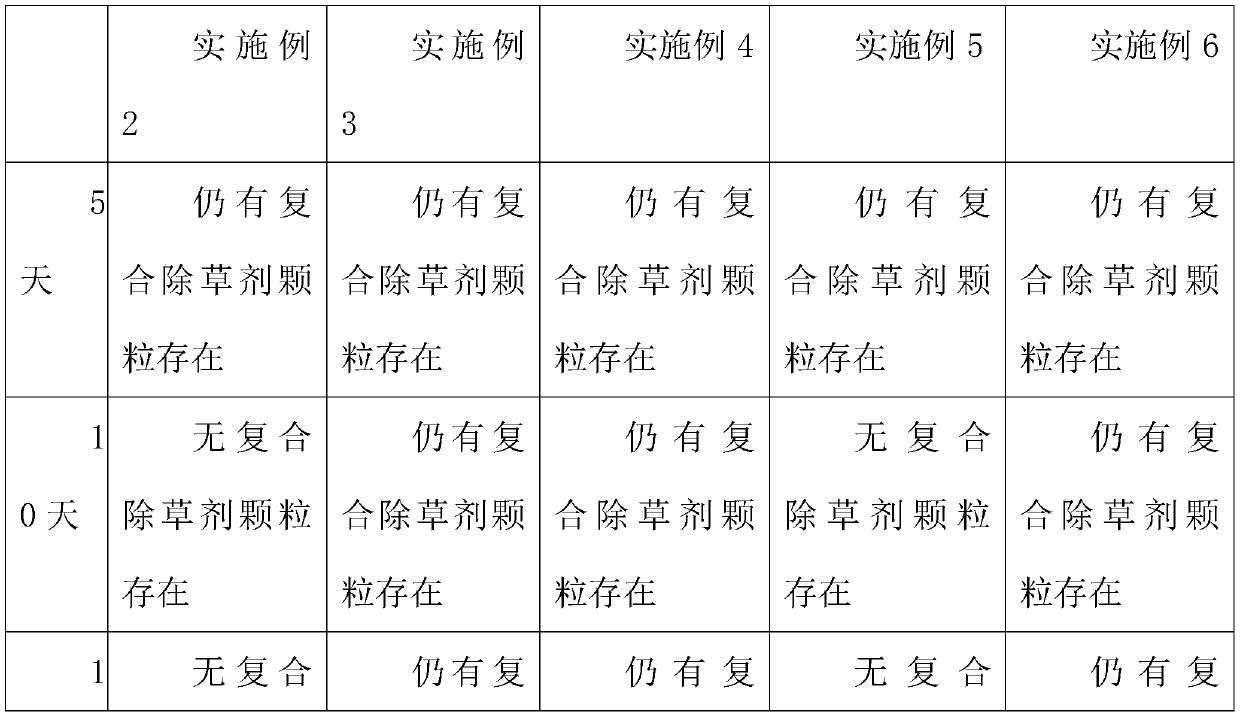

Embodiment 2

[0019] A compound herbicide, the specific preparation process is as follows:

[0020] In the first step, 1 kg of cornstarch was weighed and added to 20 L of acetic acid solution with pH=5-5.5, after mixing and stirring evenly, 22 g of α-amylase was added thereto, stirred and reacted for 8-9 hours at room temperature, and then the pH of the reaction solution was adjusted to 10, Continue to stir and react for 5-10 minutes, filter and wash the product to neutrality and dry to obtain microporous starch;

[0021] In the second step, add 1kg of the microporous starch prepared in the first step into 5L of thionyl chloride solution, ultrasonically disperse for 30-40min, then add the dispersion into the reaction kettle, raise the temperature to 70-80°C and stir for 6-7h, Then filter, wash and dry to obtain the chlorinated starch base;

[0022] In the third step, add 1kg of the chlorinated starch base prepared in the second step into 10L of ether, and disperse ultrasonically for 30-40 ...

Embodiment 3

[0026]A compound herbicide, the specific preparation process is as follows:

[0027] In the first step, 1 kg of cornstarch was weighed and added to 20 L of acetic acid solution with pH=5-5.5, after mixing and stirring evenly, 22 g of α-amylase was added thereto, stirred and reacted for 8-9 hours at room temperature, and then the pH of the reaction solution was adjusted to 10, Continue to stir and react for 5-10 minutes, filter and wash the product to neutrality and dry to obtain microporous starch;

[0028] In the second step, add 1kg of the microporous starch prepared in the first step into 5L of thionyl chloride solution, ultrasonically disperse for 30-40min, then add the dispersion into the reaction kettle, raise the temperature to 70-80°C and stir for 6-7h, Then filter, wash and dry to obtain the chlorinated starch base;

[0029] In the third step, add 1kg of the chlorinated starch base prepared in the second step into 10L of ether, and disperse ultrasonically for 30-40 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com