Rapid bed-moving system for large-area butterfly orchid seedlings

A large-area, orchid technology, applied in the field of agricultural machinery, can solve the problems of low work efficiency, large labor, low labor efficiency, etc., and achieve the effect of improving production efficiency and quality, improving work efficiency, and improving the degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

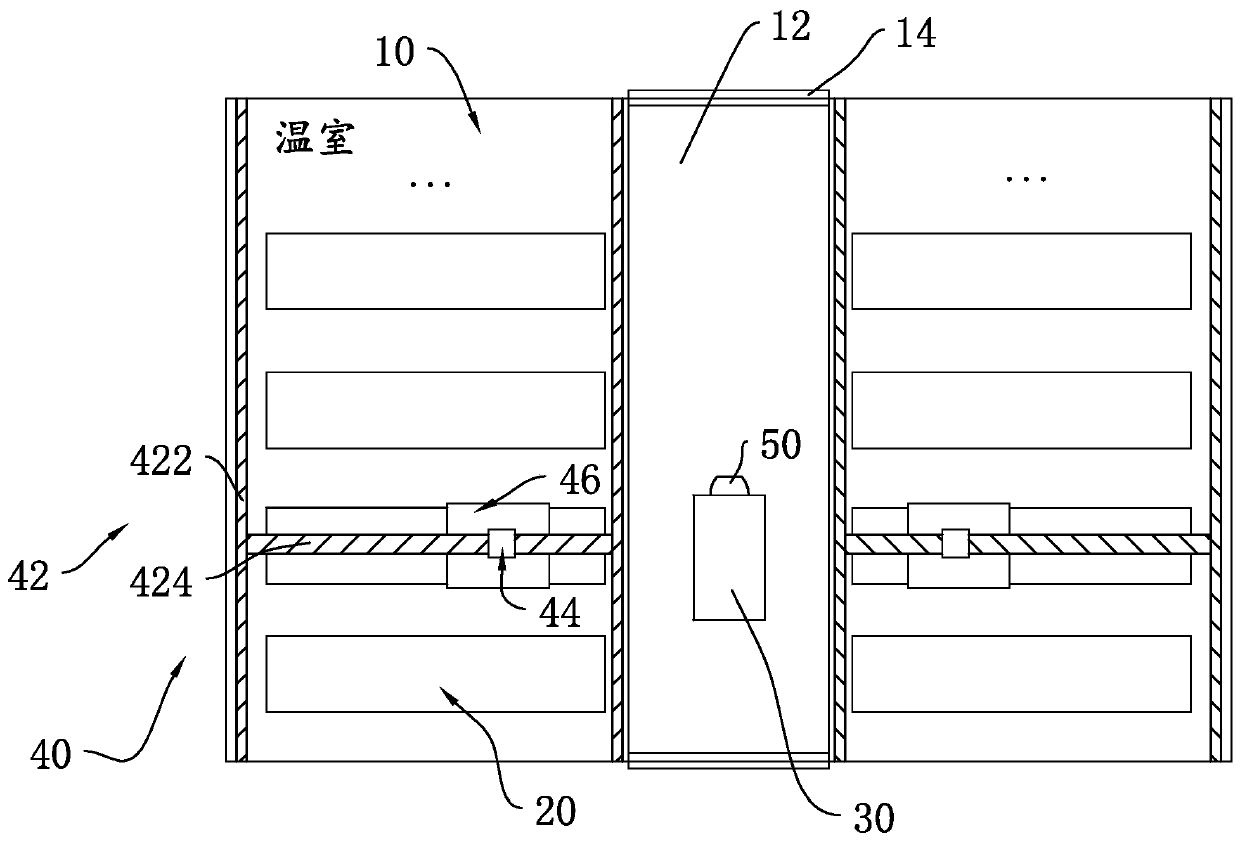

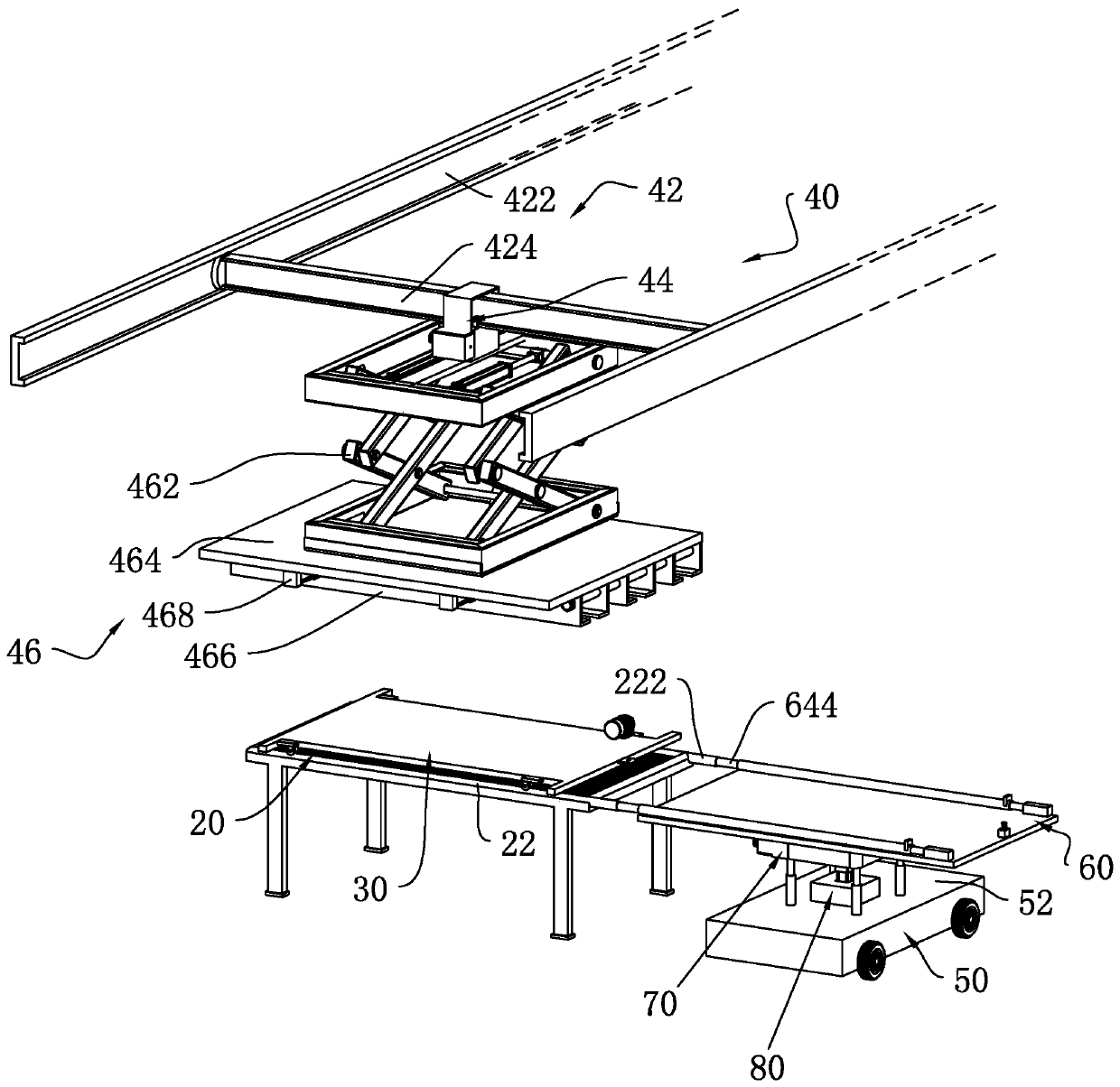

[0059] refer to figure 1 and figure 2 is a large-area phalaenopsis seedling rapid bed transfer system disclosed by the present invention, which mainly realizes the rapid transfer of large-area phalaenopsis seedlings between different seedbeds 20 in the same greenhouse 10 and seedbeds 20 in different greenhouses 10. transfer.

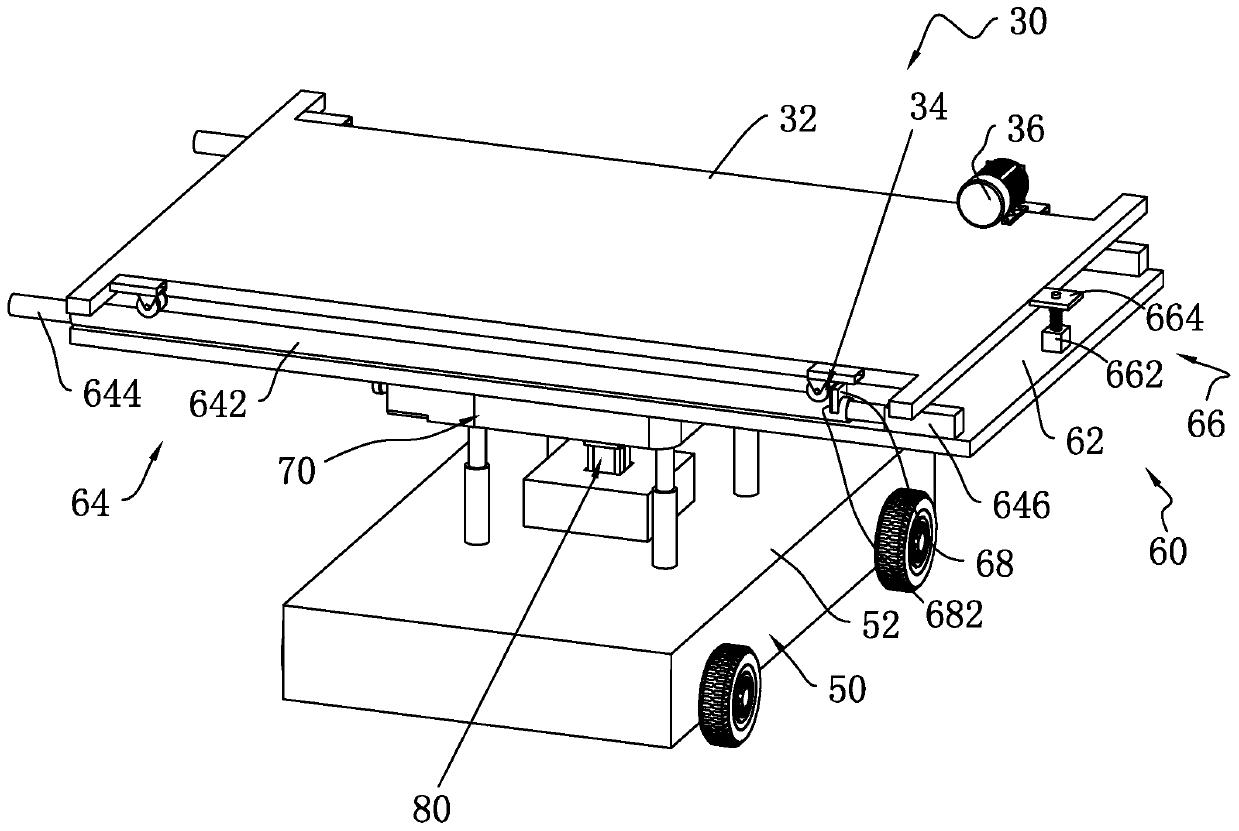

[0060] The system mainly includes a greenhouse 10, a seedbed 20, a seedling transplanting block 30, an aerial grabbing device 40, a movable vehicle 50, a positioning bracket 60, a horizontal rotation mechanism 70, and a vertical lifting mechanism 80.

[0061] main reference figure 1 , the layout of the seedbed 20 in the greenhouse 10 can adopt the traditional layout method, the middle of the greenhouse 10 is provided with a walking passage 12, and the two ends of the walking passage 12 correspond to the greenhouse door 14 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com