Fluorine indium glass ceramic containing erbium ion doped strontium fluoride and yttrium fluoride mixed crystals, and preparation method thereof

A glass ceramic and mixed crystal technology is applied in the field of fluorindium indium glass ceramic and its preparation, which can solve the problems of difficult manipulation, complicated preparation and limitation, and achieve the effects of high-efficiency fluorescence emission, convenient operation and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of raw materials: 32InF by mole percentage 3 -28BaF 2 -22ZnF 2 -12SrF 2 -6YF 3 -1ErF 3 Weigh 20g of batch material, and weigh 13.3g of ammonium bifluoride according to the mass ratio of batch material to ammonium bifluoride 1.5.

[0019] Mixing of raw materials: Mix and grind the batch material and ammonium bifluoride in a ball mill for 20 minutes to powder.

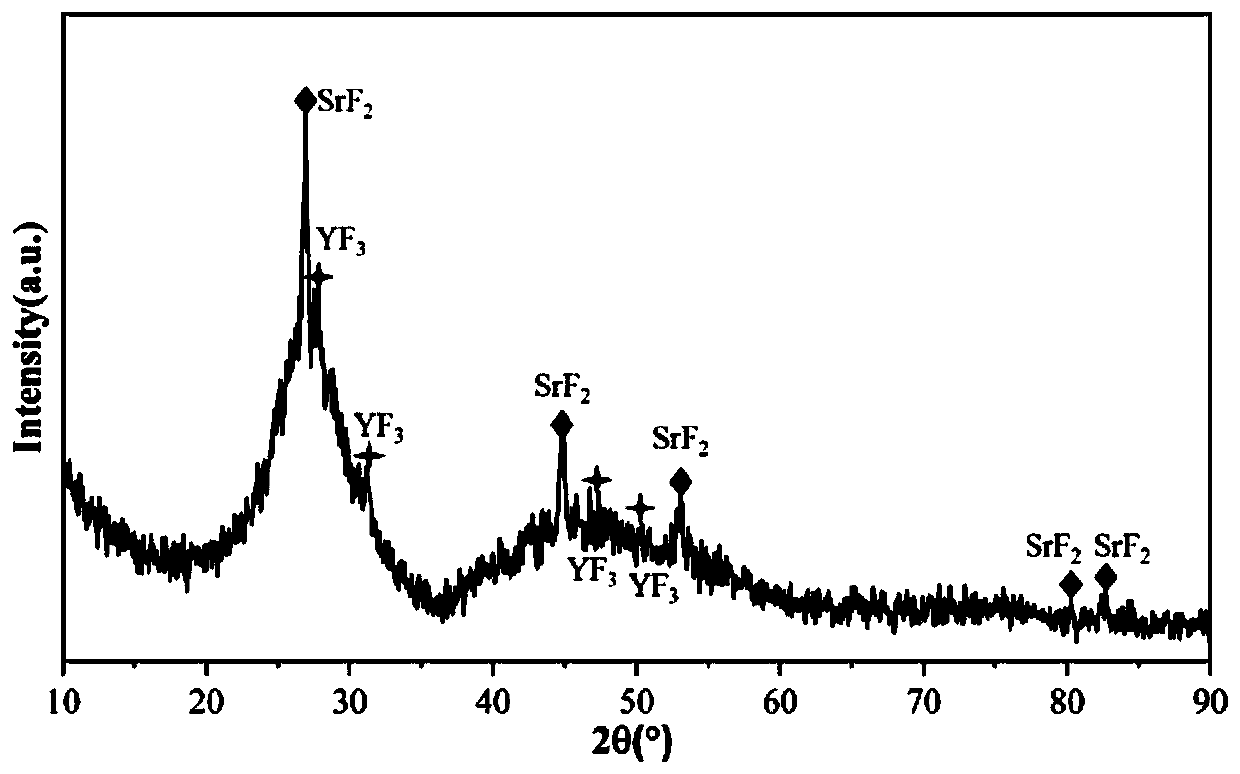

[0020] Melting and quenching: put the mixture in a platinum crucible, melt it at 800°C for 0.5 hours to obtain a molten liquid, cast the molten liquid in a square groove of a brass mold, and cover the groove with a brass abrasive strip , to obtain Er with uniform thickness 3 + :SrF 2 -YF 3 Mixed crystal transparent thin plate fluorine indium glass ceramics.

[0021] Cutting and polishing: cut and polish according to requirements to make regular blocks containing Er 3+ :SrF 2 -YF 3 Mixed crystal transparent fluorine indium glass ceramics.

Embodiment 2

[0023] Preparation of raw materials: 32InF by mole percentage 3 -28BaF 2 -22ZnF 2 -12.7SrF 2 -5.3YF 3 -1ErF 3 Weigh 20g of the batch material, and weigh 13.3g of ammonium bifluoride according to the weight ratio m being 1.5.

[0024] Mixing of raw materials: Mix and grind the batch material and ammonium bifluoride in a ball mill for 30 minutes to powder.

[0025] Melting and quenching: put the mixture in a platinum crucible, melt it at 800°C for 0.6 hours to obtain a molten liquid, cast the molten liquid into a square groove in a brass mold, and cover the groove with a brass abrasive strip , to obtain Er with uniform thickness 3 + :SrF 2 -YF 3 Mixed crystal transparent thin plate fluorine indium glass ceramics.

[0026] Cutting and polishing: cut and polish according to requirements to make regular blocks containing Er 3+ :SrF 2 -YF 3 Mixed crystal transparent fluorine indium glass ceramics.

Embodiment 3

[0028] Preparation of raw materials: 30InF by mole percentage 3 -28BaF 2 -22ZnF 2 -14.1SrF 2 -5.9YF 3 -1ErF 3 Weigh 20g of the batch material, and weigh 13.3g of ammonium bifluoride according to the weight ratio m being 1.5.

[0029] Mixing of raw materials: Mix and grind the batch material and ammonium bifluoride in a ball mill for 40 minutes to powder.

[0030] Melting and quenching: the mixture is placed in a platinum crucible, melted at 810°C for 0.4 hours to obtain molten glass, which is cast in a square groove of a brass mold, and covered with a brass abrasive strip on the groove, Obtain Er-containing 3+ :SrF 2 -YF 3 Mixed crystal transparent thin plate fluorine indium glass ceramics.

[0031] Cutting and polishing: cut and polish according to requirements to make regular blocks containing Er 3+ :SrF 2 -YF 3 Mixed crystal transparent fluorine indium glass ceramics.

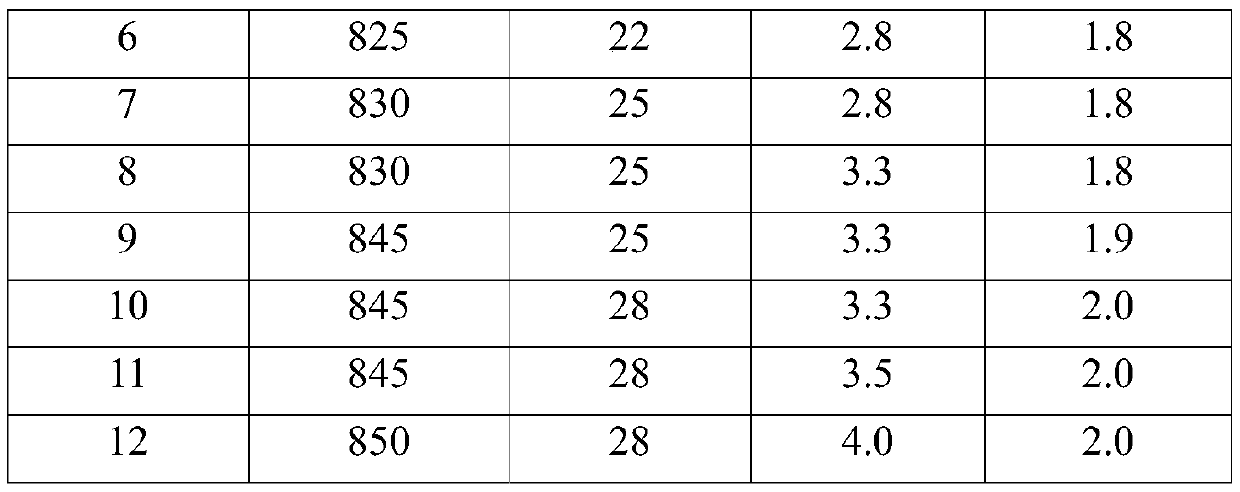

[0032] The rest of the implementation parameters are shown in the table below:

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com