Production Technology of Large Unit Weight Extra Thick Chromium Molybdenum Steel Plate

A production process and large single-weight technology, applied in the field of metallurgy, can solve the problems of single-weight steel plate, blank or steel plate judgment, and fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

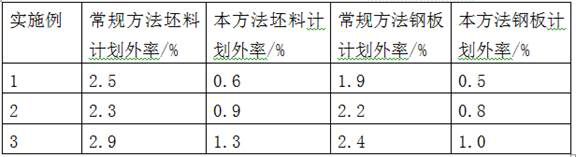

Embodiment 1

[0014] Embodiment 1: The production process of this large single-weight and extra-thick chromium-molybdenum steel plate is as follows.

[0015] The steel grade is SA387Gr22CL2, the forging ingot is heated to 1250°C and forged into a forging billet with a weight of 95t. The forged billet is put into the furnace at 25°C and slowly raised to 180°C for 4 hours at a heating rate of 30°C / h, followed by heating at a rate of 50°C / h to 400°C for 10 hours, and then released from the furnace. Heating after coming out of the furnace, the heating temperature is 1310°C, the soaking temperature is 1300°C, and the holding time is 10h. Then rolling is carried out at a rolling start temperature of 1100° C., and rolled into a steel plate with a thickness of 420 mm and a weight of 62 t. After testing, there are no defects such as cracks and cracks in the blanks and finished steel plates, and the surface quality is good.

Embodiment 2

[0016] Embodiment 2: The production process of this large single-weight and extra-thick chromium-molybdenum steel plate is as follows.

[0017] For steel type 10CrMo9-10, the forging ingot is heated to 1250°C and forged into a forging billet with a weight of 100t. The forged billet is put into the furnace at 75°C and slowly raised to 190°C for 4.5 hours at a heating rate of 29°C / h, followed by heating at a rate of 49°C / h to 430°C for 11 hours, and then released from the furnace. Heating after coming out of the furnace, the heating temperature is 1300°C, the soaking temperature is 1280°C, and the holding time is 11h. Rolling is then carried out at a rolling start temperature of 1080°C to form a steel plate with a thickness of 450mm and a weight of 65t. After testing, there are no defects such as cracks and cracks in the blanks and finished steel plates, and the surface quality is good.

Embodiment 3

[0018] Embodiment 3: The production process of the large single-weight and extra-thick chromium-molybdenum steel plate is as follows.

[0019] For the steel type 10CrMo910, the forging ingot is heated to 1250°C and forged into a forging billet with a weight of 107t. The forged billet is put into the furnace at 100°C and slowly raised to 200°C for 5 hours at a heating rate of 28°C / h, followed by heating at a rate of 48°C / h to 450°C for 12 hours, and then released from the furnace. Heating after coming out of the furnace, the heating temperature is 1330°C, the soaking temperature is 1290°C, and the holding time is 12h. Then rolling is carried out at a rolling start temperature of 1140° C., and rolled into a steel plate with a thickness of 500 mm and a weight of 70 t. After testing, there are no defects such as cracks and cracks in the blanks and finished steel plates, and the surface quality is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com