Chestnut paste essence and preparation method thereof

A technology of chestnut paste and chestnut, which is applied in the directions of food ingredients as odor modifiers, food science, sugary food ingredients, etc., can solve the problems of complex operation process, no literature reports chestnut flavor essence preparation, chestnut paste essence preparation and the like, and achieves The effect of short time, low temperature, good aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

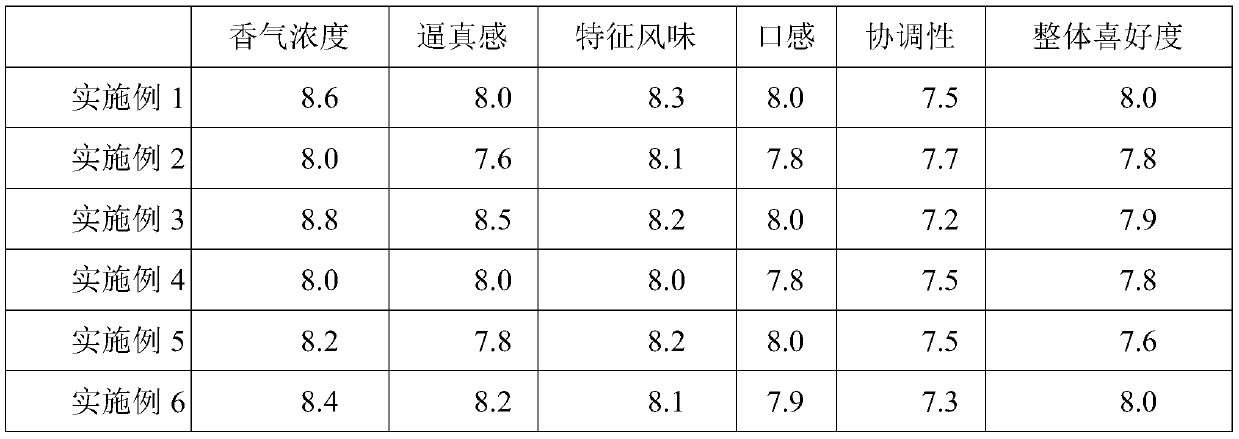

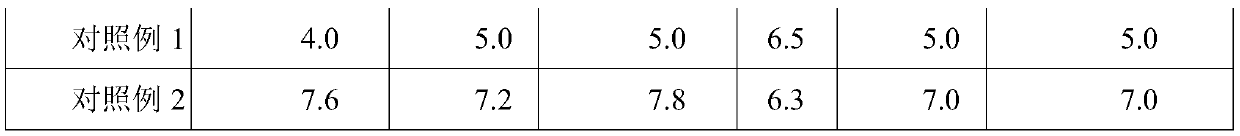

Examples

preparation example Construction

[0028] A preparation method of chestnut paste essence as above, comprises the following steps:

[0029] 1) Take each raw material according to the above;

[0030] 2) Proline, arginine, serine, aspartic acid, monosodium glutamate, furanone, sugar source, VB 1 Mix it with water evenly, put it into the reaction kettle, stir, and cool to obtain the chestnut hot reactant;

[0031] 3) adding chestnut powder, sucrose, edible salt, monosodium glutamate, salad oil, corn starch, xanthan gum and potassium sorbate to the chestnut heat reactant in step 2), stirring and gelatinizing, and cooling to obtain heat-reaction chestnut paste;

[0032] 4) Heat-reaction chestnut paste and chestnut base are evenly mixed to obtain chestnut paste essence.

[0033] Preferably, in step 2), the reaction is stirred at 96-105°C for 1-2.5 hours, and then cooled to 72-75°C.

[0034] Preferably, step 3) stir and gelatinize at 80-90°C for 15-25 minutes, and then cool to 60-63°C.

Embodiment 1

[0036] A chestnut paste essence, the preparation steps are as follows:

[0037] (1) Counting according to parts by weight, weigh 0.5 part of proline, 0.7 part of arginine, 0.8 part of serine, 0.3 part of aspartic acid, 0.2 part of monosodium glutamate, 0.4 part of furanone, 3 parts of glucose, 1.5 part of fructose, 4 parts of sucrose, 0.5 part of xylose, vitamin B 1 (VB 1 ) 0.06 parts, water 65 parts, mixed uniformly, put into the reaction kettle, under the condition of reaction temperature of 98 ℃, reacted for 2.5 hours, cooled to 72 ℃, obtained chestnut heat reactant;

[0038] (2) Count according to parts by weight, weigh 80 parts of chestnut heat reactant prepared in step (1), 12 parts of chestnut powder, 1 part of sucrose, 2 parts of salt, 1 part of monosodium glutamate, 1 part of salad oil, 2 parts of cornstarch , 0.1 part of xanthan gum, 0.1 part of potassium sorbate, after mixing evenly, raise the temperature to 90°C, stir and keep it warm for 20 minutes, then cool do...

Embodiment 2

[0041] A chestnut paste essence, the preparation steps are as follows:

[0042] (1) Count according to parts by weight, weigh 0.8 part of proline, 0.5 part of arginine, 0.6 part of serine, 0.2 part of aspartic acid, 0.4 part of monosodium glutamate, 0.2 part of furanone, 2 parts of glucose, 1 part of fructose, 4 parts sucrose, VB 1 0.1 part, 70 parts of water, mixed evenly, put into the reaction kettle, reacted for 1.5 hours at the reaction temperature of 102°C, cooled to 72°C, and obtained the hot chestnut reactant;

[0043] (2) counting according to parts by weight, take by weighing 75 parts of chestnut heat reactant prepared in step (1), then take by weighing 5 parts of chestnut powder, 2 parts of sucrose, 1.5 parts of salt, 0.6 part of monosodium glutamate, 1.5 parts of salad oil, 4 parts of cornstarch, 0.2 part of xanthan gum, and 0.06 part of potassium sorbate. After mixing the weighed raw materials evenly, heat up to 85°C, stir and keep warm for 25 minutes, and cool do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com