Preparation method of strongly-fragrant and total-nutrition soybean milk powder and application

A nutritious bean, strong aroma technology, applied in applications, dairy products, milk substitutes, etc., can solve problems such as resource waste and environmental pollution, and achieve the effects of easy operation, simple equipment, and strong aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

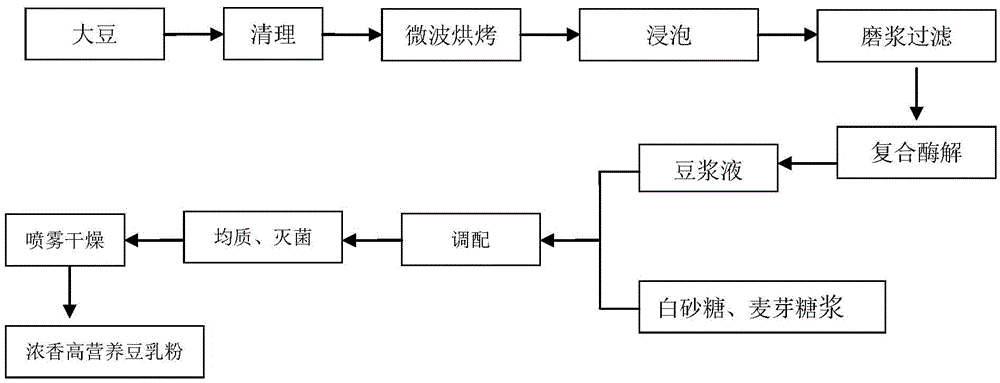

[0034] A preparation method of Luzhou-flavored full-nutrition soymilk powder, the method comprising the following steps: (1) After the soybeans are selected and removed, they are preliminarily crushed to 10-15 petals, and placed in a microwave roasting machine for microwave roasting treatment , the microwave output power is 7-12kW, and the baking time is 5-12min; (2) after the soybeans are peeled by microwave roasting, soak the beans with a NaHCO3 aqueous solution with a concentration of 0.5%-1.0% for 12h-16h, and then grind them Add 8 times of boiling water to the pulp machine to refine the pulp, and boil the soybean milk at 91°C-95°C for 10 minutes to obtain a mixture of pulp and residue. The residue part obtained by filtering and separating is subjected to compound enzymatic hydrolysis treatment. The conditions of the compound enzymatic hydrolysis are firstly the compound enzymatic hydrolysis pH of neutral cellulase and low-temperature amylase is 6.0-8.0, the enzymatic hydro...

Embodiment 1

[0039] After the soybeans are selected and removed, they are preliminarily crushed to 10-15 petals, and placed in a microwave oven for microwave baking treatment. The microwave output power is 9kW, and the baking time is 8 minutes; 0.5% NaHCO 3 Soak the soybeans in an aqueous solution for 12 hours, then use a refiner to add 8 times of boiling water to refine the soybean milk, and boil the soybean milk at 92°C for 10 minutes to obtain a mixture of pulp and residue. The residue part obtained by filtration and separation is subjected to compound enzymatic hydrolysis treatment, in which neutral cellulase and low-temperature amylase compound enzymatic hydrolysis pH 6.5, enzymatic hydrolysis temperature 45°C, neutral cellulase addition amount 300U / mL, low-temperature amylase addition Amount of 80U / mL, enzymolysis time 1.5h, then enzymatic hydrolysis of flavor proteolysis pH 7.0, enzyme addition 120U / mL, enzymolysis time 0.5h, enzymolysis temperature 45°C; ℃ inactivate enzyme treatm...

Embodiment 2

[0041] After the soybeans are selected and removed, they are initially crushed to 10-15 petals, and placed in a microwave oven for microwave baking treatment. The microwave output power is 7kW, and the baking time is 12 minutes; 0.5% NaHCO 3 Soak the beans in an aqueous solution for 16 hours, then use a refiner to add 8 times of boiling water to refine the soybean milk, and boil the soybean milk at 95°C for 10 minutes to obtain a mixture of pulp and residue. The residue part obtained by filtration and separation is subjected to compound enzymatic hydrolysis treatment, in which neutral cellulase and low-temperature amylase compound enzymatic hydrolysis pH 6.0, enzymatic hydrolysis temperature 50°C, neutral cellulase addition amount 200U / mL, low-temperature amylase addition 100U / mL, enzymolysis time 1h, then enzymatic hydrolysis of flavor proteolysis pH 7.6, enzyme addition 100U / mL, enzymolysis time 1h, enzymolysis temperature 50℃; Redissolve in soybean milk after enzyme treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com