Extra-high temperature liquid metallurgical slag waste heat recovery device and waste heat recovery system

A technology of waste heat recovery device and waste heat recovery system, which is applied in boiler cleaning device, preheating, liquid degassing, etc., can solve the problems of large shock frequency, large temperature change span and high temperature of heat exchange system, so as to improve the safety of use. , the effect of reducing the impact frequency and reducing the temperature span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

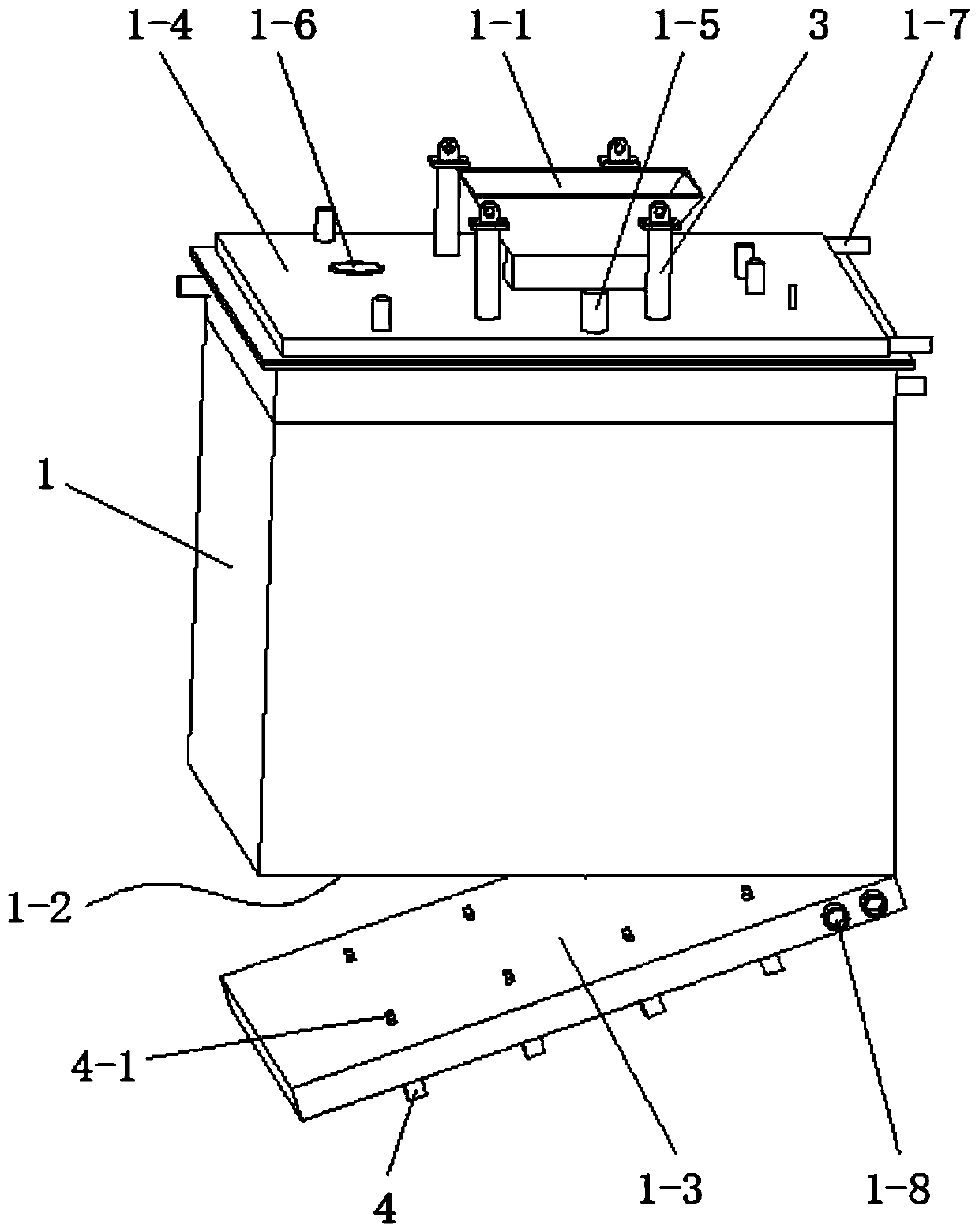

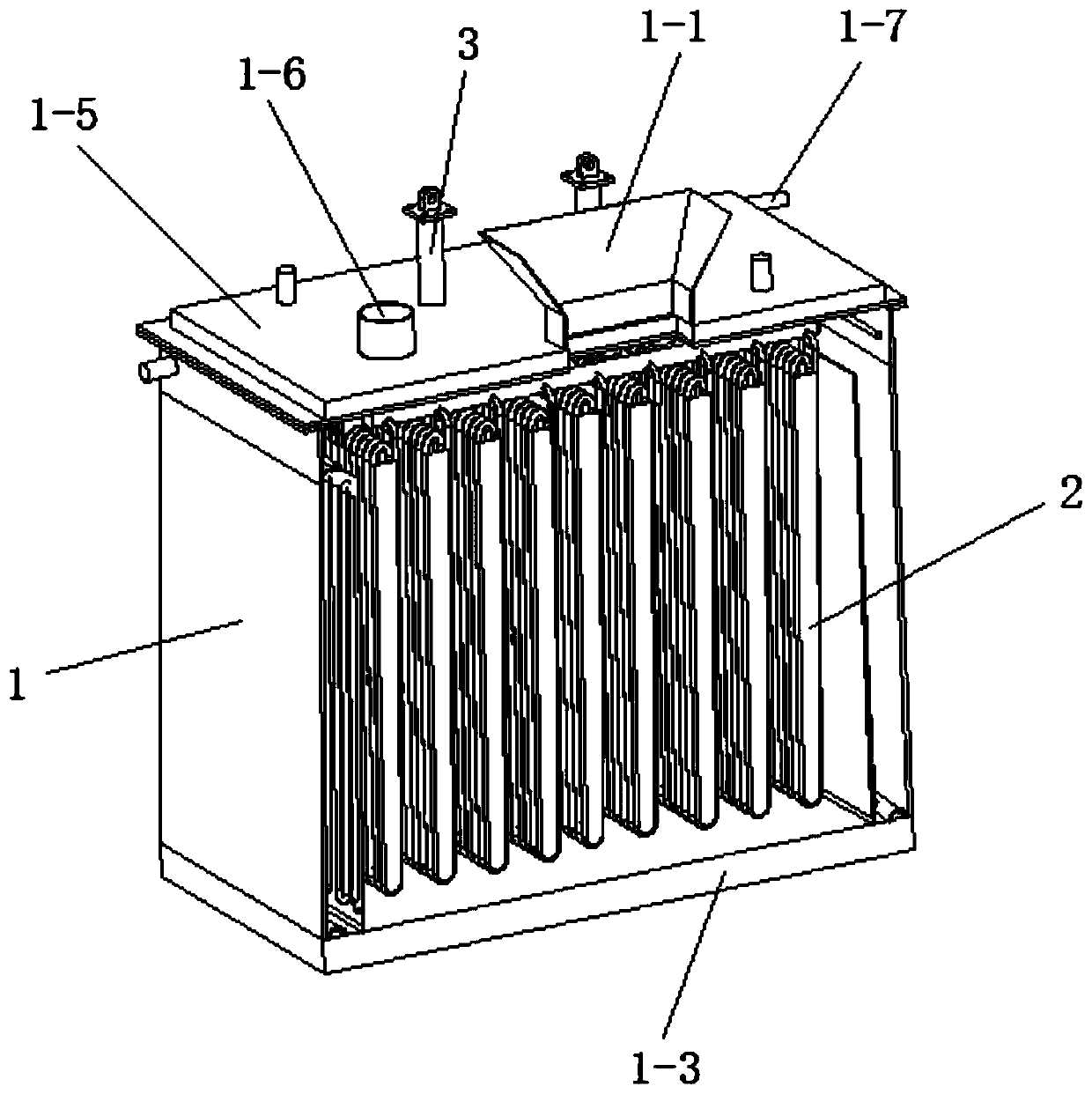

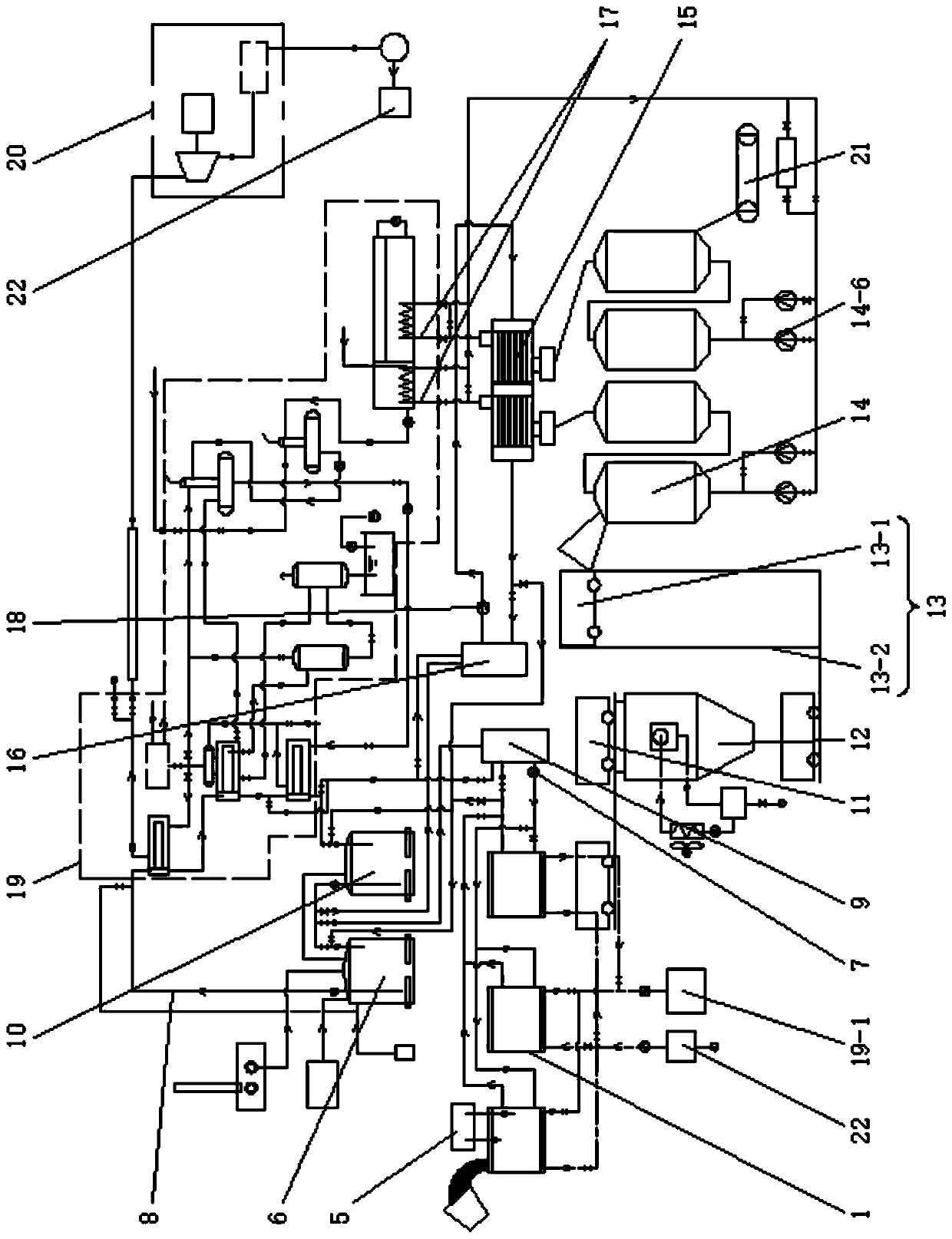

[0057] See Figure 1 to Figure 9 , the waste heat recovery device for ultra-high temperature liquid metallurgical slag in the present invention includes a heat exchange box 1; the heat exchange box 1 is provided with an inlet 1-1 for the ultra-high temperature liquid metallurgical slag to flow into the heat exchange box 1 ; The heat exchange box 1 is provided with a heat exchange assembly 2 for absorbing the heat of the ultra-heated high-temperature liquid metallurgical slag, and the heat exchange assembly 1 is also provided on the side walls around the heat exchange box 1 2. The bottom surface of the heat exchange box 1 is provided with a discharge port 1-2, and the discharge port 1-2 is provided with a quick-opening door 1-3 which can control the opening or closing of the discharge port 1-2;

[0058] The heat exchange box 1 is also provided with a jacking assembly; the jacking assembly includes a plurality of power jacks 3, and a first driving device that drives the power ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com