A high-strength q500gje quenched and tempered state building structure steel plate and its manufacturing method

A manufacturing method and building structure technology, applied in the field of special steel metallurgy, can solve the problems of complex production process, uneven rolling structure, long rolling period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

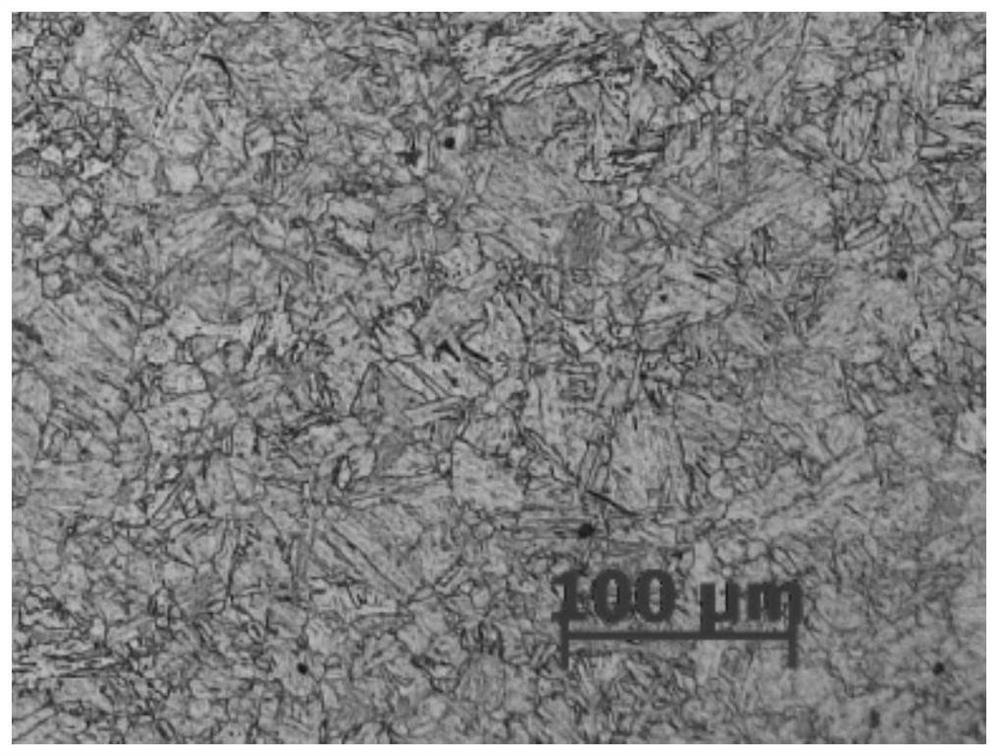

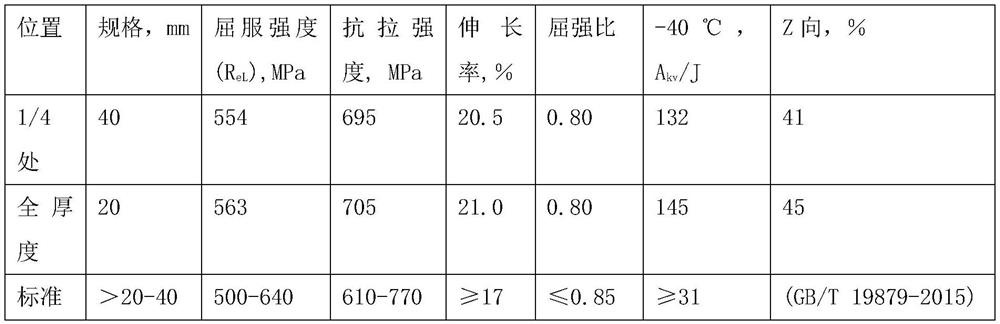

example 1

[0051] Example 1: A 370mm thick continuous casting billet was used to produce a rolled 40mm thick steel plate. The continuous casting slab is 370×2300×3200mm, and the rolled finished plate is 40×2600×L (length) mm. The blank is cold loaded into the heating furnace. The temperature of the preheating section of the heating furnace: 650-700℃, the temperature of the heating section: 1000-1050℃, the temperature of the second heating section: 1150-1200℃, the temperature of the soaking section: 1180-1220℃; Total time 220 minutes. After rough rolling, the thickness of the waiting temperature is 88mm; after warming, the starting temperature of the finishing mill is 820°C, rolling through the finishing mill, and the final rolling temperature is 810°C; it is leveled by a hot straightening machine; Roll off the production line at 335°C for slow cooling; after 37 hours of slow cooling, the appearance quality inspection of the steel plate is carried out; qualified plates are transferred to...

example 2

[0052] Example 2: Design and use 150mm thick continuous casting billet to produce and roll 20mm thick steel plate. The continuous casting slab used is 150×2400×3500 mm, and the rolled finished plate is 12×2800×L (length) mm. The billet is cold-loaded into the heating furnace, and the heating process is the same as the example 1. After rough rolling to a thickness of 65mm, it is sent to the finishing mill for rolling, and the final rolling temperature is 795°C; after rolling, the rolled piece is directly sent to the hot straightening machine for leveling; after hot rolling, cooling can be further controlled: the temperature of the steel plate after hot straightening Control at 480°C; quickly water-cool to 400°C at a cooling rate of 40°C / s, then send it to a cooling bed for natural cooling for 10 minutes, then slowly water-cool to 300±20°C, slow cooling at a cooling rate of 18 / °C / s, then off-line stack Slow cooling, stacking and slow cooling for more than 48 hours; then finishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com