Organically modified nanometer zirconium phosphate coated ammonium polyphosphate and preparation method thereof

A technology of nano-zirconium phosphate and ammonium polyphosphate, which is applied in the field of flame retardants, can solve the problems of poor performance of composite materials, poor stability, poor compatibility and weather resistance, and increased particle size of APP, so as to achieve safe and non-toxic raw materials. Toxicity, easy industrial production, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

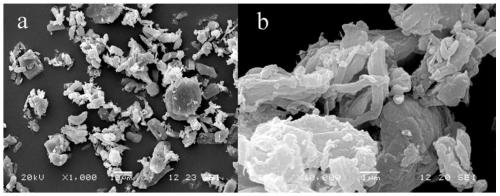

Image

Examples

Embodiment 1

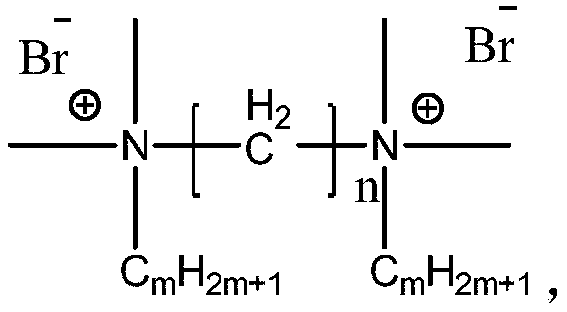

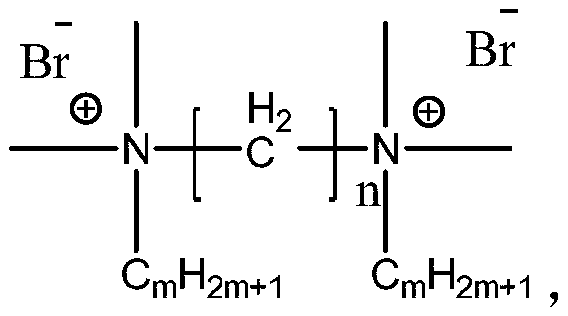

[0027] 25g layered zirconium phosphate, 2.5g G 4,12 Place in a 500mL three-neck flask, add 200mL of ethanol, and stir the resulting mixture ultrasonically at 30°C for 5 hours, filter and wash with ethanol twice, 50mL each time, to obtain modified zirconium phosphate for later use.

[0028] Put 25g of modified zirconium phosphate and 150mL of acetonitrile in a 500mL single-necked flask, stir ultrasonically at room temperature for half an hour to fully disperse, then add 10g of KH-550 to the flask, raise the temperature to 90°C and stir for 24 hours to obtain modified zirconium phosphate Dispersions.

[0029] Add 100g of ammonium polyphosphate to the above dispersion, stir and react at 90°C for 20 hours, cool to room temperature and filter after the reaction, and dry the filter cake at 70°C for 5 hours to obtain organically modified nano-zirconium phosphate-coated ammonium polyphosphate.

Embodiment 2

[0031] 10g layered zirconium phosphate, 1.5g G 2,14Place in a 500mL three-neck flask, add 200mL of ethanol, and stir the resulting mixture ultrasonically at 35°C for 6 hours, filter and wash with ethanol twice, 50mL each time, to obtain modified zirconium phosphate for later use.

[0032] Put 10g of modified zirconium phosphate and 200mL of dioxane in a 500mL single-necked flask, stir ultrasonically at room temperature for 1 hour to fully disperse, then add 8g of KH-540 to the flask, raise the temperature to 100°C and stir for 24 hours to obtain the modified zirconium phosphate dispersion.

[0033] Add 80g of ammonium polyphosphate to the above dispersion, stir and react at 100°C for 18 hours, cool to room temperature and filter after the reaction, and dry the filter cake at 80°C for 6 hours to obtain organically modified nano-zirconium phosphate-coated ammonium polyphosphate.

Embodiment 3

[0035] 25g layered zirconium phosphate, 2.5g G 5,14 Place in a 500mL three-neck flask, add 250mL of ethanol, and stir the resulting mixture ultrasonically at 30°C for 8 hours, filter and wash with ethanol three times, 50mL each time, to obtain modified zirconium phosphate for use.

[0036] Put 20g of modified zirconium phosphate and 200mL of acetonitrile in a 500mL single-necked flask, stir ultrasonically at room temperature for 1 hour to fully disperse, then add 10g of KH-902 to the flask, raise the temperature to 90°C and stir for 20 hours to obtain modified zirconium phosphate Dispersions.

[0037] Add 100g of ammonium polyphosphate to the above dispersion, stir and react at 90°C for 20 hours, cool to room temperature and filter after the reaction, and dry the filter cake at 70°C for 5 hours to obtain organically modified nano-zirconium phosphate-coated ammonium polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com