3D printing ceramic nano powder and preparation method thereof

A 3D printing and nano-powder technology, applied in the field of 3D printing materials, can solve the problems of poor compatibility between inorganic particles and polymer bodies, low curing shrinkage of mechanical properties, etc., and achieve low curing shrinkage, high mechanical properties, performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

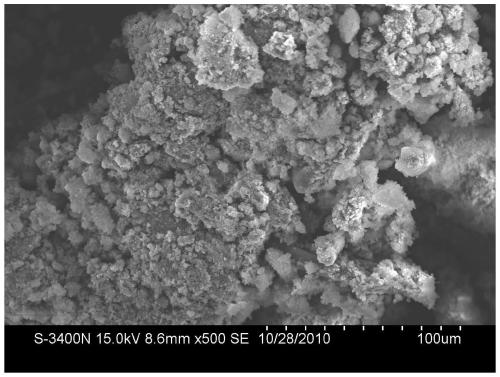

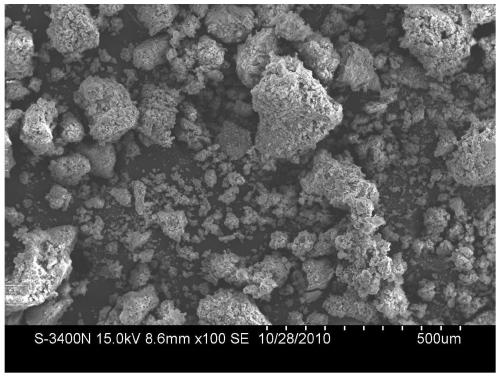

Image

Examples

Embodiment 1

[0024] The 3D printing ceramic nanopowder of present embodiment, raw material comprises following components: sodium silicate solution and photothermal initiator, and the mixed solution of trimethylolpropane triacrylate and acrylic acid; The quality of described sodium silicate solution The concentration is 1%; the quality of the photothermal initiator is 0.3% of the quality of the sodium silicate solution, and the mass content of trimethylolpropane triacrylate in the mixed solution of trimethylolpropane triacrylate and acrylic acid 50%.

[0025] The photothermal initiator is a mixture of 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxy cyclohexyl phenyl ketone and 2, The mass ratio of 4,6-trimethylbenzoyl-diphenylphosphine oxide is 1:1.

[0026] The preparation method of the 3D printing ceramic nanopowder of this embodiment is:

[0027] Step 1. Add sodium silicate to deionized water, heat and stir to dissolve the sodium silicat...

Embodiment 2

[0033] The 3D printing ceramic nanopowder of present embodiment, raw material comprises following components: sodium silicate solution and photothermal initiator, and the mixed solution of trimethylolpropane triacrylate and acrylic acid; The quality of described sodium silicate solution The concentration is 25%; the quality of the photothermal initiator is 0.5% of the quality of the sodium silicate solution, and the mass content of trimethylolpropane triacrylate in the mixed solution of trimethylolpropane triacrylate and acrylic acid was 33.3%.

[0034] The photothermal initiator is a mixture of 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxy cyclohexyl phenyl ketone and 2, The mass ratio of 4,6-trimethylbenzoyl-diphenylphosphine oxide is 1:0.05.

[0035] The preparation method of the 3D printing ceramic nanopowder of this embodiment is:

[0036] Step 1. Add sodium silicate to deionized water, heat and stir to dissolve the sodi...

Embodiment 3

[0042] The 3D printing ceramic nanopowder of present embodiment, raw material comprises following components: sodium silicate solution and photothermal initiator, and the mixed solution of trimethylolpropane triacrylate and acrylic acid; The quality of described sodium silicate solution The concentration is 50%; the quality of the photothermal initiator is 5% of the quality of the sodium silicate solution, and the mass content of trimethylolpropane triacrylate in the mixed solution of trimethylolpropane triacrylate and acrylic acid 25%.

[0043] The photothermal initiator is a mixture of 1-hydroxycyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxy cyclohexyl phenyl ketone and 2, The mass ratio of 4,6-trimethylbenzoyl-diphenylphosphine oxide is 1:3.

[0044] The preparation method of the 3D printing ceramic nanopowder of this embodiment is:

[0045] Step 1. Add sodium silicate to deionized water, heat and stir to dissolve the sodium silicate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com