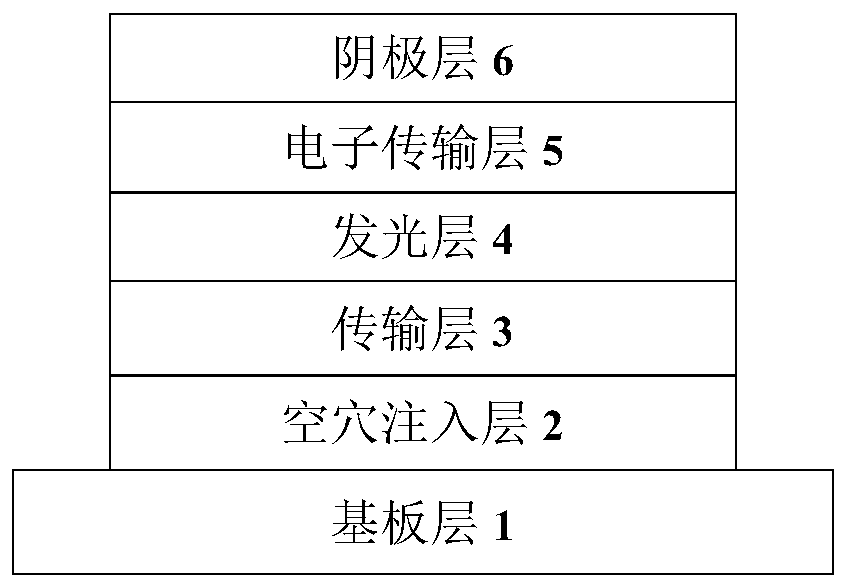

Thermal activated delayed fluorescence material, preparation method and electroluminescence device

A technology of heat-activated delayed and fluorescent materials, applied in the direction of luminescent materials, electric solid devices, chemical instruments and methods, etc., can solve the problems of lack of heavy metal Ir complexes, etc., and achieve high efficiency, high luminous efficiency, and increased luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

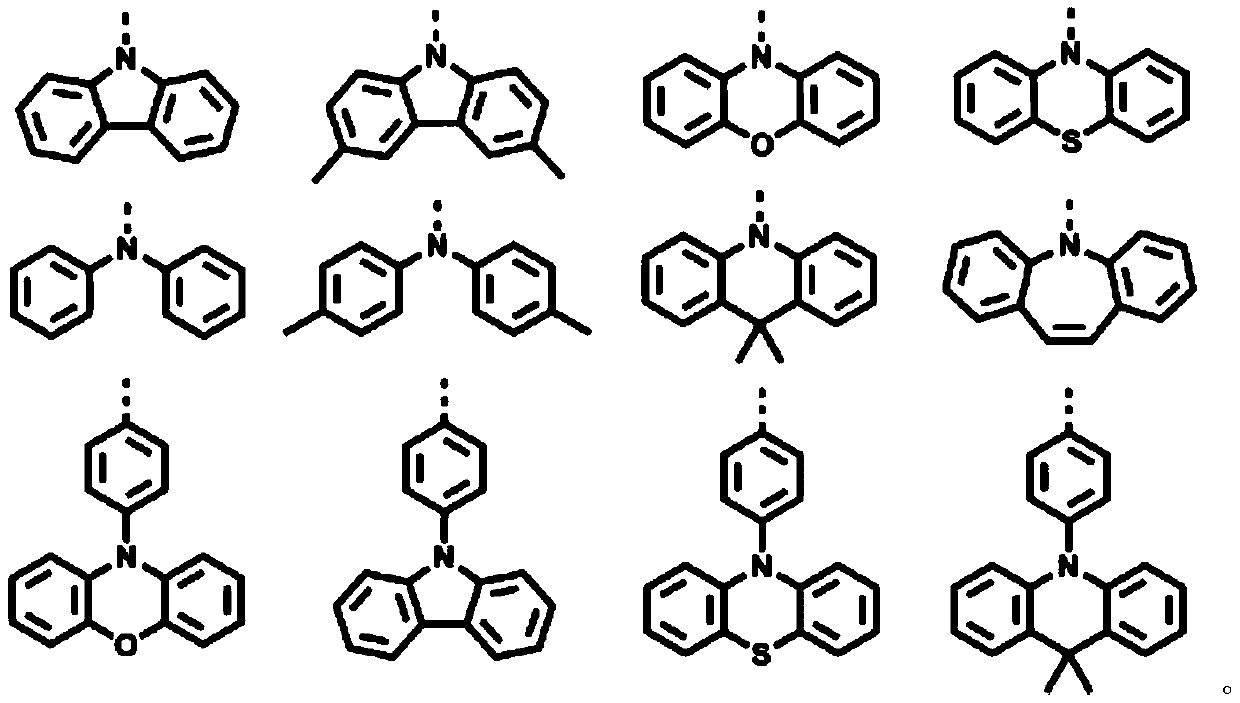

[0046] Synthetic fluorescent material compound 1, the synthetic route is as follows:

[0047]

[0048] Synthetic steps:

[0049] Add raw material 1 to a 100mL two-necked bottle (proportioning 4.00g, molar weight 5mmol), carbazole (proportioning 1.00g, molar weight 6mmol), palladium acetate (Pd(OAc) 2 ) (proportion 45mg, molar weight 0.2mmol) and tri-tert-butylphosphine tetrafluoroborate ((t-Bu) 3 HPBF 4 ) (proportioning 0.17g, molar weight 0.6mmol), then, in the glove box, add NaOt-Bu (proportioning 0.58g, molar weight 6mmol), inject 50mL of toluene that dehydrates and deoxygenates in advance under an argon atmosphere, React at 120°C for 24 hours. Cool to room temperature, pour the reaction solution into 200mL ice water, extract three times with dichloromethane, combine the organic phases, spin into silica gel, and separate and purify by column chromatography (dichloromethane:n-hexane, v:v, 1:3), to obtain Light blue powder 2.6g, yield 59%. After mass spectrometry ...

Embodiment 2

[0051] Synthetic fluorescent material compound 2, the synthetic route is as follows:

[0052]

[0053] Synthetic steps:

[0054] Add raw material 1 to a 100mL two-necked bottle (Proportioning 4.00g, molar weight 5mmol), diphenylamine (1.01g, 6mmol), palladium acetate (Pd(OAc) 2 ) (proportioning 45mg, molar weight 0.2mmol) and tri-tert-butylphosphine tetrafluoroborate ((t-Bu) 3 HPBF 4 ) (proportioning 0.17g, molar weight 0.6mmol), then, in the glove box, add NaOt-Bu (proportioning 0.58g, molar weight 6mmol), inject 50mL of toluene that dehydrated and deoxygenated in advance under an argon atmosphere, React at 120°C for 24 hours. Cool to room temperature, pour the reaction solution into 200mL ice water, extract three times with dichloromethane, combine the organic phases, spin into silica gel, and separate and purify by column chromatography (dichloromethane:n-hexane, v:v, 1:3) to obtain Light blue powder 2.2g, yield 50%. After mass spectrometry analysis, MS (EI) m / z...

Embodiment 3

[0056] Synthetic fluorescent material compound 3, the synthetic route is as follows:

[0057]

[0058] Add raw material 1 to a 100mL two-necked bottle (proportion 4.00g, molar weight 5mmol), 9,9'-dimethylacridine (2.51g, 6mmol), palladium acetate (Pd(OAc) 2 ) (ratio 45mg, molar weight 0.2mmol) and tri-tert-butylphosphine tetrafluoroborate ((t-Bu) 3 HPBF 4 ) (proportioning 0.17g, molar weight 0.6mmol), then, in the glove box, add NaOt-Bu (proportioning 0.58g, molar weight 6mmol), inject 50mL of toluene that dehydrates and deoxygenates in advance under an argon atmosphere, React at 120°C for 24 hours. Cool to room temperature, pour the reaction solution into 200mL ice water, extract three times with dichloromethane, combine the organic phases, spin into silica gel, and separate and purify by column chromatography (dichloromethane:n-hexane, v:v, 1:3) to obtain Light blue powder 2.9g, yield 63%. After mass spectrometry analysis, MS (EI) m / z: 928.28.

[0059] Theoretica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com