Heat-preservation fireproof integral plate and manufacturing method thereof

A manufacturing method and thermal insulation technology, which is applied in the field of building material manufacturing, can solve problems such as inconvenient use, and achieve the effect of large wall hanging force, high strength, and good load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

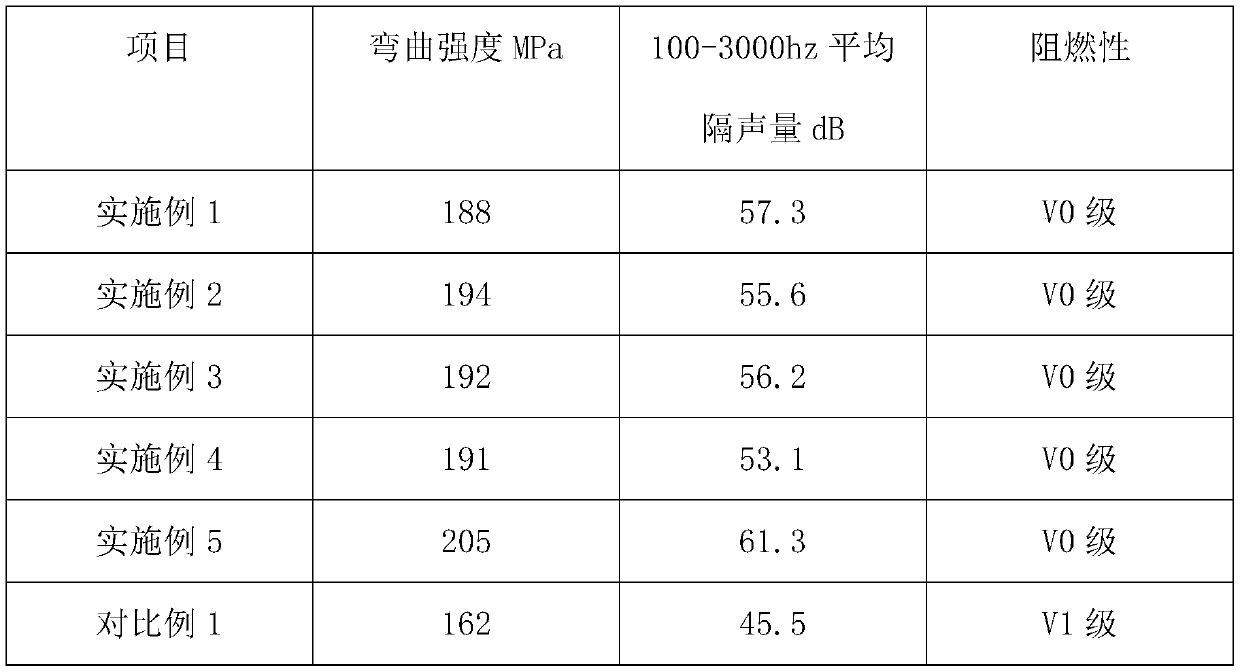

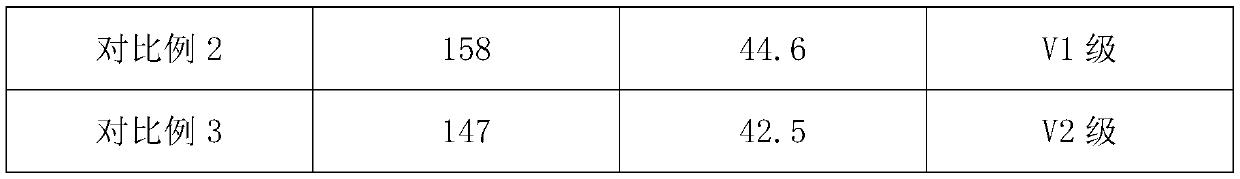

Examples

Embodiment 1

[0025] A thermal insulation and fireproof integrated board, comprising the following components: 100 parts of magnesium oxide, 10 parts of polyphenylene particles, 40 parts of magnesium oxysulfate, 8 parts of sodium gelling acid, 8 parts of sawdust, and 10 parts of fly ash.

[0026] The production process of the building board includes the following steps:

[0027] Step 1: adding water with a volume ratio of 1:4 to the gelled sodium, then stirring evenly to obtain the gelled sodium solution;

[0028] Step 2: Add magnesium oxide, polyphenylene particles, magnesium oxysulfate, sawdust, and fly ash into the mixer, then add water with a volume ratio of 1:1, stir and mix evenly, and obtain mixture A;

[0029] Step 3: adding sodium gelling acid solution to mixture A and stirring and mixing to obtain mixture B;

[0030] Step 4: The mixture B is evenly distributed on the assembly line by the distributor and cut, and then put into the curing rack for 24 hours;

[0031] Step 5: cuttin...

Embodiment 2

[0033] A thermal insulation and fire prevention integrated board, comprising the following components: 140 parts of magnesium oxide, 20 parts of polyphenylene particles, 80 parts of magnesium oxysulfide, 12 parts of sodium gelling acid, 12 parts of sawdust, and 20 parts of fly ash.

[0034] The production process of the building board includes the following steps:

[0035] Step 1: adding water with a volume ratio of 1:4 to the gelled sodium, then stirring evenly to obtain the gelled sodium solution;

[0036] Step 2: Add magnesium oxide, polyphenylene particles, magnesium oxysulfate, sawdust, and fly ash into the mixer, then add water with a volume ratio of 1:1, stir and mix evenly, and obtain mixture A;

[0037] Step 3: adding sodium gelling acid solution to mixture A and stirring and mixing to obtain mixture B;

[0038] Step 4: The mixture B is evenly distributed on the assembly line by the distributor and cut, and then put into the curing rack for 24 hours;

[0039] Step 5...

Embodiment 3

[0041] A thermal insulation and fire prevention integrated board, comprising the following components: 110 parts of magnesium oxide, 12 parts of polyphenylene particles, 50 parts of magnesium oxysulfide, 9 parts of sodium gelling acid, 9 parts of sawdust, and 12 parts of fly ash.

[0042] The production process of the building board includes the following steps:

[0043] Step 1: adding water with a volume ratio of 1:4 to the gelled sodium, then stirring evenly to obtain the gelled sodium solution;

[0044] Step 2: Add magnesium oxide, polyphenylene particles, magnesium oxysulfate, sawdust, and fly ash into the mixer, then add water with a volume ratio of 1:1, stir and mix evenly, and obtain mixture A;

[0045] Step 3: adding sodium gelling acid solution to mixture A and stirring and mixing to obtain mixture B;

[0046] Step 4: The mixture B is evenly distributed on the assembly line by the distributor and cut, and then put into the curing rack for 24 hours;

[0047] Step 5: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com