Polysiloxane modified polyurethane-epoxy resin polymer material, preparation method thereof and use thereof

A technology of epoxy resin and polysiloxane, which is applied in the field of polysiloxane modified polyurethane-epoxy resin polymer material and its preparation and application, can solve the surface energy, surface hydrophobicity and weather resistance of polymer materials The performance can not be fully satisfied, etc., to achieve the effect of highlighting surface hydrophobicity, good film-forming property, low surface tension and surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

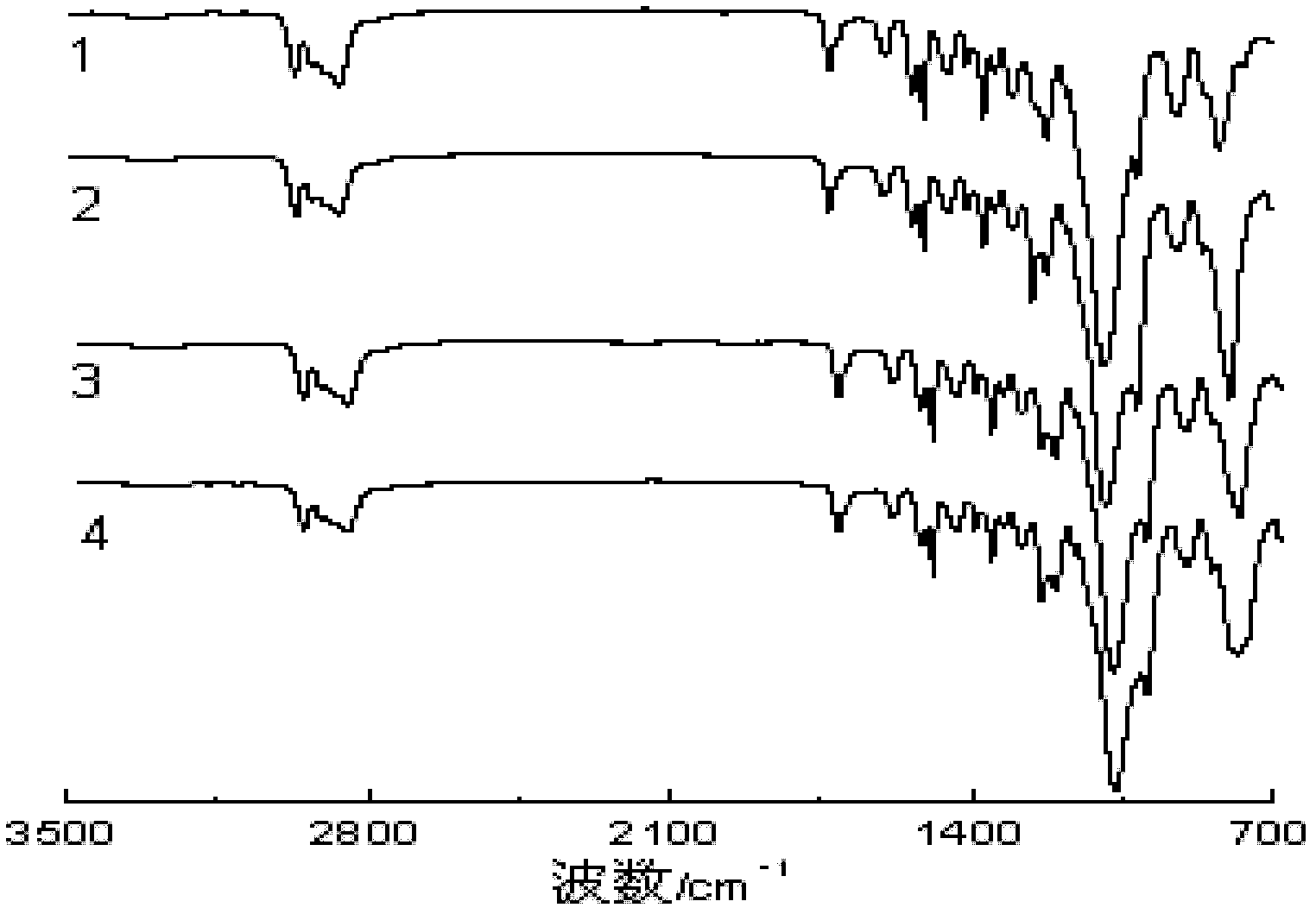

Embodiment 1

[0029] The raw materials are dried until the moisture content is below 0.01%. Add polyether N330 with a molecular weight of 4800 and toluene-2,4-diisocyanate (TDI) into a three-necked flask, add bisphenol A epoxy resin E-44 and stir evenly. After rising to 80°C for 3 hours, add 10.64 grams of liquid linear hydroxyl-terminated polysiloxane with a molecular weight of 50,000, and then raise the temperature to 100°C for 1 hour to obtain a polysiloxane-polyurethane-epoxy resin prepolymer; cool down to After 40°C, add 0.01% dibutyltin dilaurate and 0.2% ethanolamine ethyl acetate solution, stir evenly, quickly pour the viscous polymer into the prepared mold, and take it out after curing at room temperature for 24 hours. Bisphenol A type epoxy resin accounts for 5% of polyurethane-epoxy resin polymer system mass percentage content when feeding; Terminated hydroxyl polysiloxane accounts for polysiloxane-polyurethane-epoxy resin prepolymer mass percentage content 5%; the total molar ra...

Embodiment 2

[0031] Dry the raw materials until the moisture content is below 0.01%, add polyether 2000 with a molecular weight of 2000, diphenylmethane-4,4'-diisocyanate (MDI) into a three-necked flask, add bisphenol A epoxy resin E-51 and stir Evenly, heat up to 60°C for 6 hours, add 15.45 grams of trapezoidal hydroxyl-terminated polysiloxane with a molecular weight of 1,000-100,000, and raise the temperature to 80°C for 3 hours to obtain polysiloxane-polyurethane-epoxy resin Prepolymer: After cooling down to 40°C, add 2% stannous octoate and 5% diethanolamine in 2-butanone solution, stir evenly, quickly pour the viscous polymer into the prepared mold, and cure at room temperature for 24 Unmould after hours. When feeding, bisphenol A epoxy resin accounts for 25% of polyurethane-epoxy resin polymer system mass percentage content; Terminated hydroxyl polysiloxane accounts for polysiloxane-polyurethane-epoxy resin prepolymer mass percentage content of 20%; the total molar ratio of isocyana...

Embodiment 3

[0033]Dry the raw materials until the moisture content is below 0.01%, add polyether N330 with a molecular weight of 4800, diphenylmethane-4,4'-diisocyanate (MDI) into a three-necked flask, add bisphenol A epoxy resin E-51 and stir Evenly, heat up to 70°C for 5 hours, add 33.07 grams of liquid linear hydroxyl-terminated polysiloxane with a molecular weight of 50,000, and raise the temperature to 80°C to continue the reaction for 1.5 hours, then raise the temperature to 90°C for 1 hour to obtain polysiloxane Oxyalkylene-polyurethane-epoxy resin prepolymer; after cooling down to 40°C, add 1% dibutyltin dilaurate and 2% ethyl acetate solution of diethanolamine, stir well, and quickly pour the viscous polymer into In the prepared mold, it was cured at room temperature for 24 hours and then removed from the mold. When feeding, bisphenol A epoxy resin accounts for 50% of polyurethane-epoxy resin polymer system mass percentage content; Terminated hydroxyl polysiloxane accounts for po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com