Fabricated steel-concrete structure modular camp house building system

A steel-concrete structure and modularization technology, applied in the direction of construction and building structure, can solve the problems of not being able to assemble modular steel structure houses at the same time, low installation efficiency, poor stability, etc., so as to save the supporting process, The effect of reducing engineering cost and quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

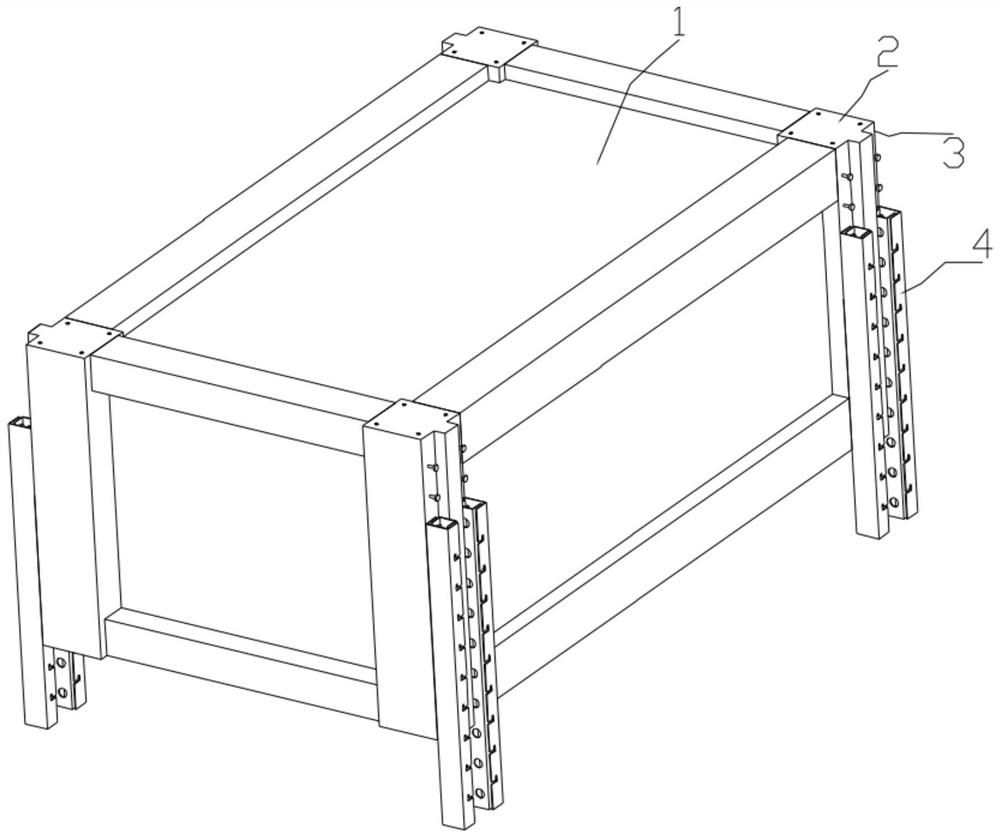

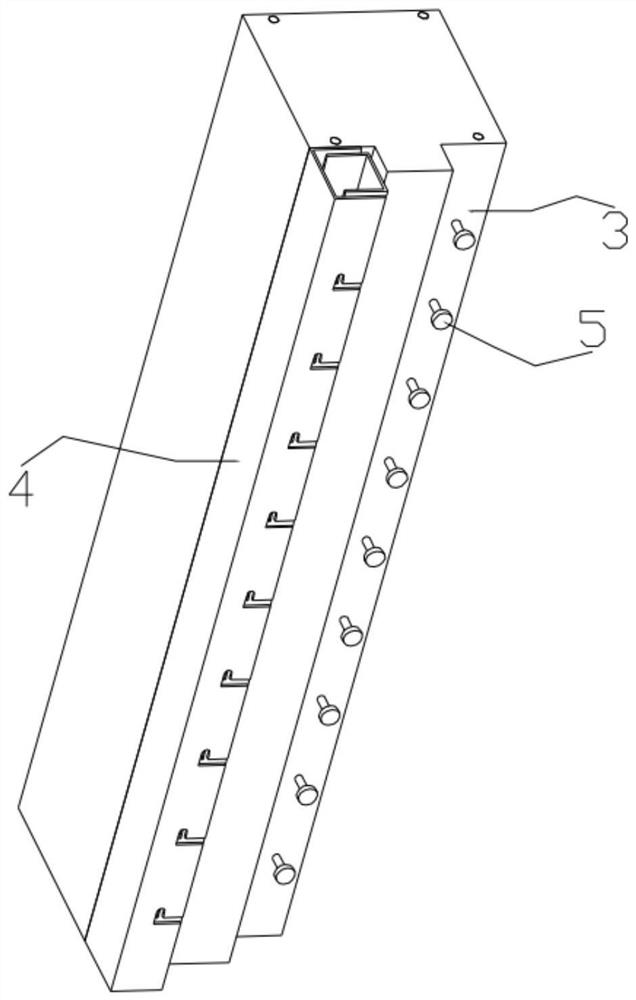

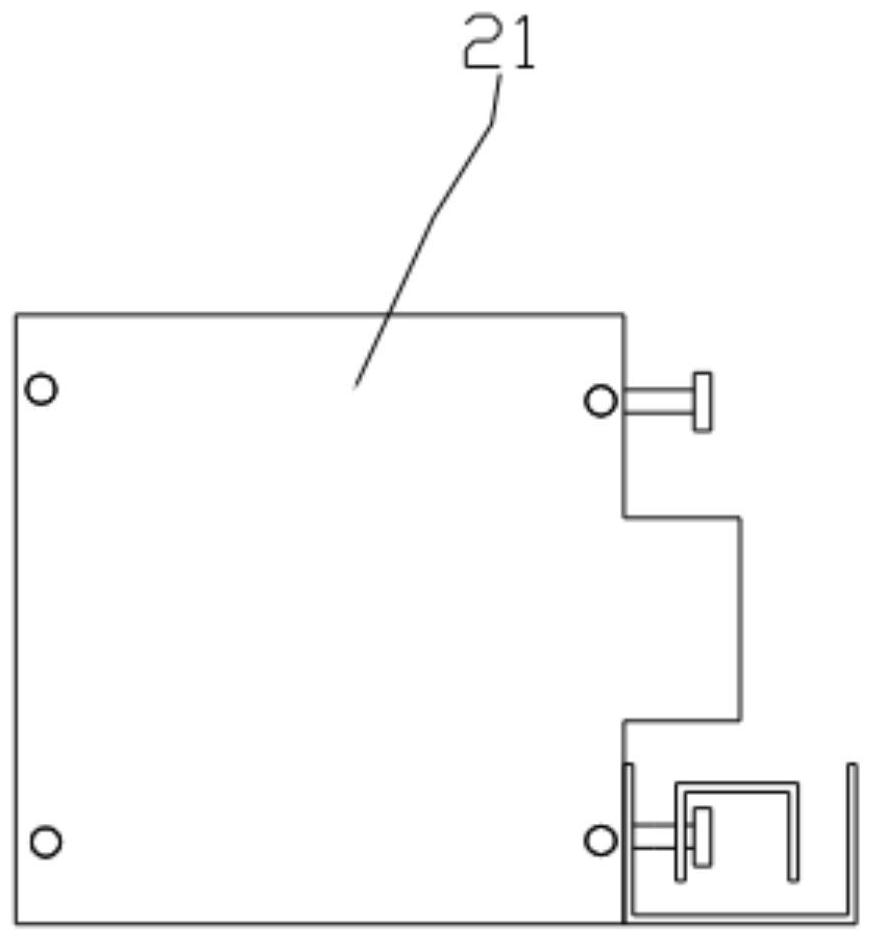

[0033] like figure 1 As shown in the figure, an assembled steel-concrete structure modular camp house building system of the present invention includes a house main body 1 and four support columns 2 arranged at the four corners of the house main body 1. The house main body 1 is hexahedral, and the support columns 2 are square. Column-shaped, located at the four corners of the main body 1 of the house. like Figures 2 to 5 As shown, right-angled grooves 3 are provided on the inner and outer sides of the support column 2. The right-angled grooves 3 extend along the length direction of the support column 2, and the upper and lower ends pass through, so that the outer middle of the support column 2 is formed with a protrusion. A first connecting portion extends outward from the bottom surface of one side of each right-angled groove 3 , and the first connecting portions are evenly spaced in the vertical direction. A U-shaped outer connector 4 is provided, and the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com