Integrated assembly type pipe gallery based on composite bottom plate and construction method thereof

A prefabricated, bottom plate technology, applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve problems such as section breakage, laminated plates and cushions are not tightly bonded, etc., to facilitate installation and positioning, reduce use and The amount of template usage and the effect of reducing the amount of template usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

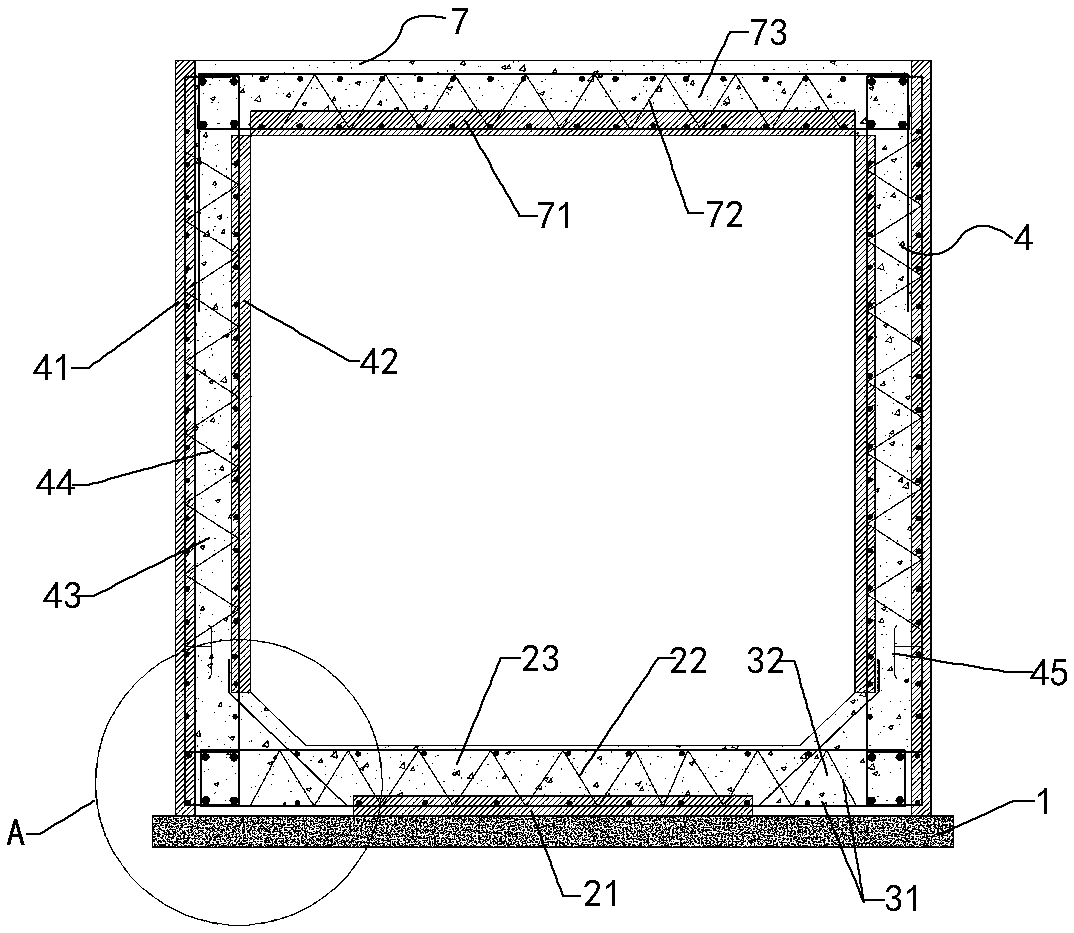

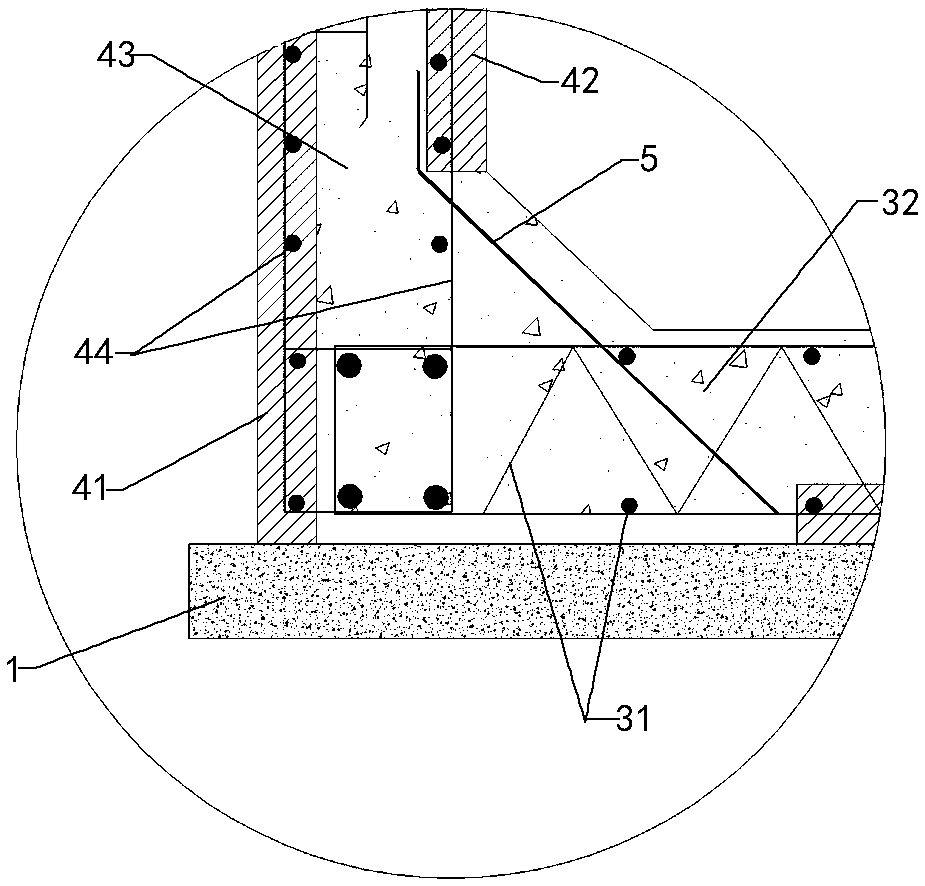

[0047] Such as figure 1 and figure 2 As shown, the integrated assembled pipe gallery based on the composite floor of the present invention is enclosed by a composite floor, double-layer laminated wall panels 4 and laminated roof panels 7 .

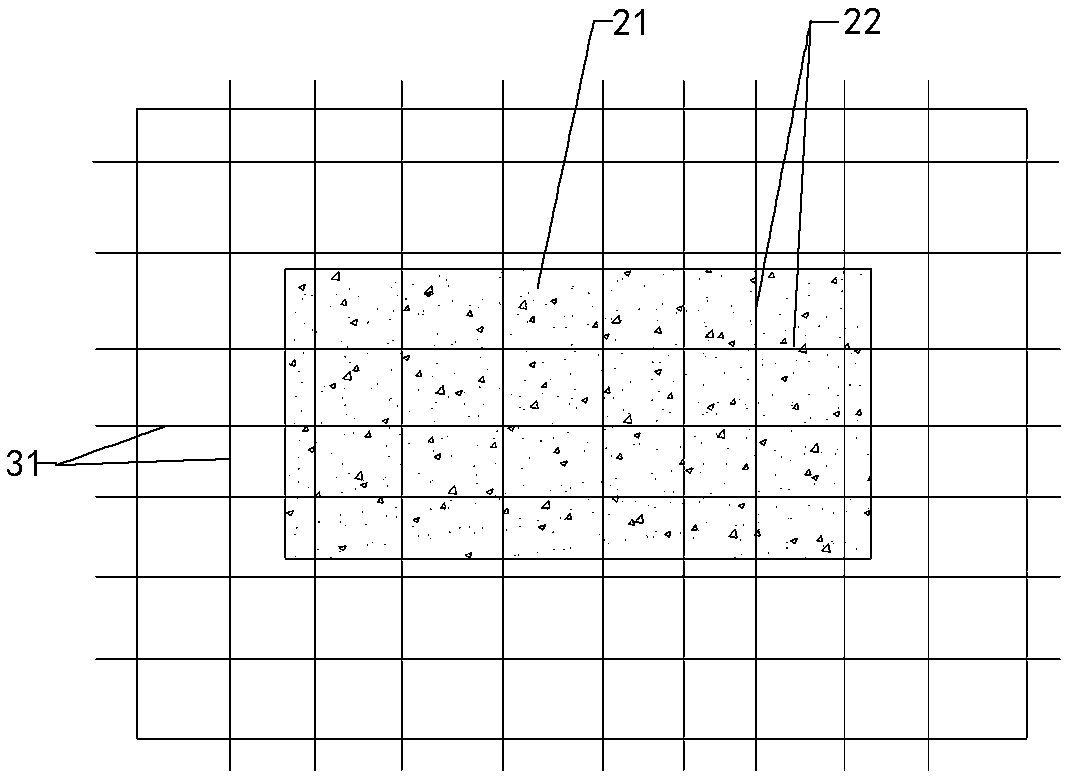

[0048] Such as image 3 As shown, the composite bottom plate is horizontally arranged on the foundation cushion 1, and is composed of multiple unit plates spliced along the length direction of the pipe gallery. Each unit plate includes a superimposed part and a cast-in-place part. The cast-in-place part is located around the superimposed part. The edges on both sides are respectively connected to the bottom of the double-layer laminated wall panels 4 on both sides of the pipe gallery. The floor area of the laminated part in each unit plate is not less than 30% of the floor area of the unit plate. The horizontal distance between the inner surfaces of the side double-layer laminated wall panels 4 is not less than 500mm; The embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com