Novel vacuum foam-plastic hydraulic molding machine with double-rod oil cylinders

A molding machine and oil cylinder technology, which is applied in the field of new double-rod oil cylinder vacuum foam plastic hydraulic molding machine, can solve the problems of inconvenient mold installation, increased enterprise cost, and easy deformation of the oil cylinder, so as to achieve convenient mold height adjustment, improve production efficiency, Guaranteeing the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

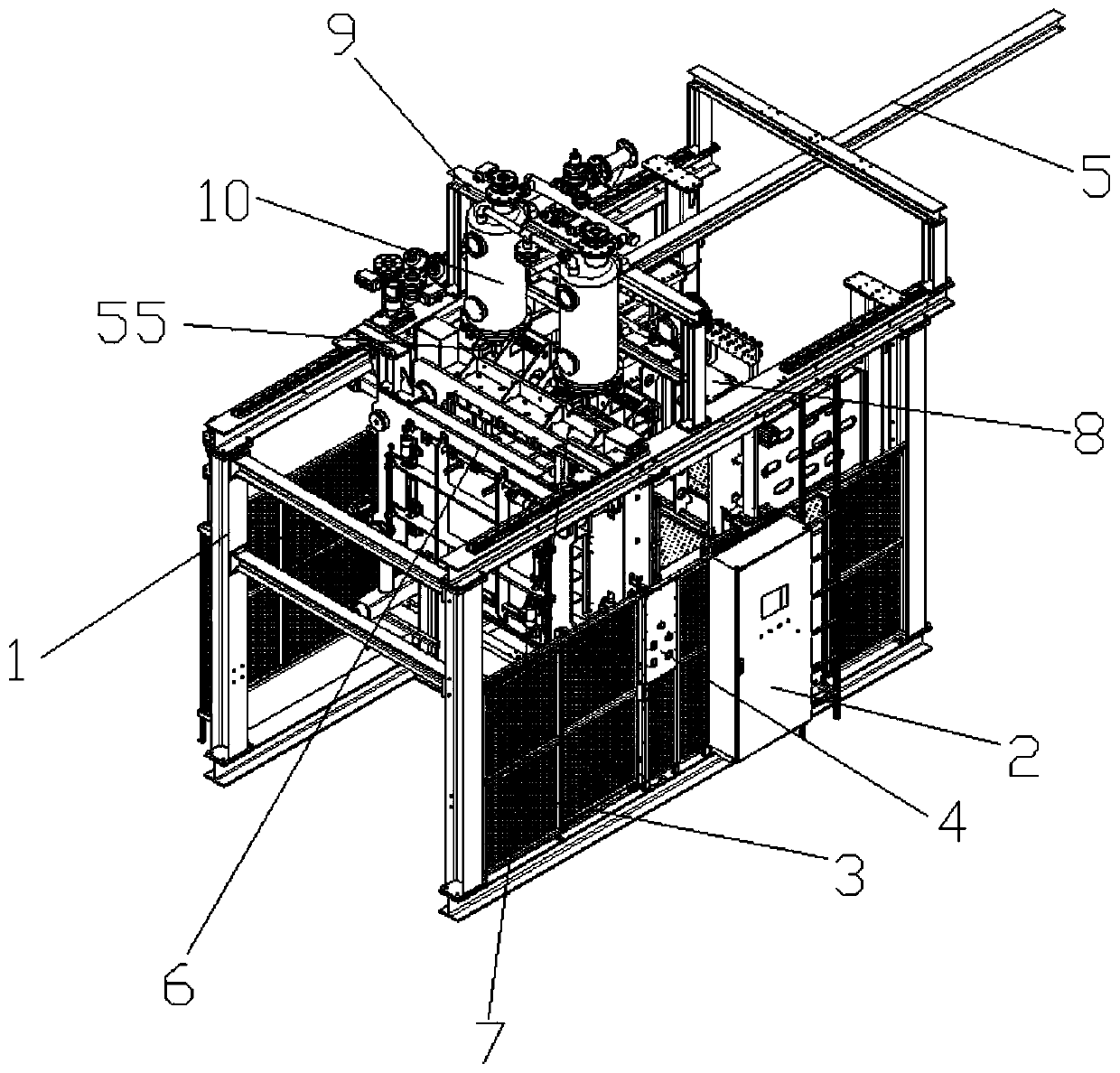

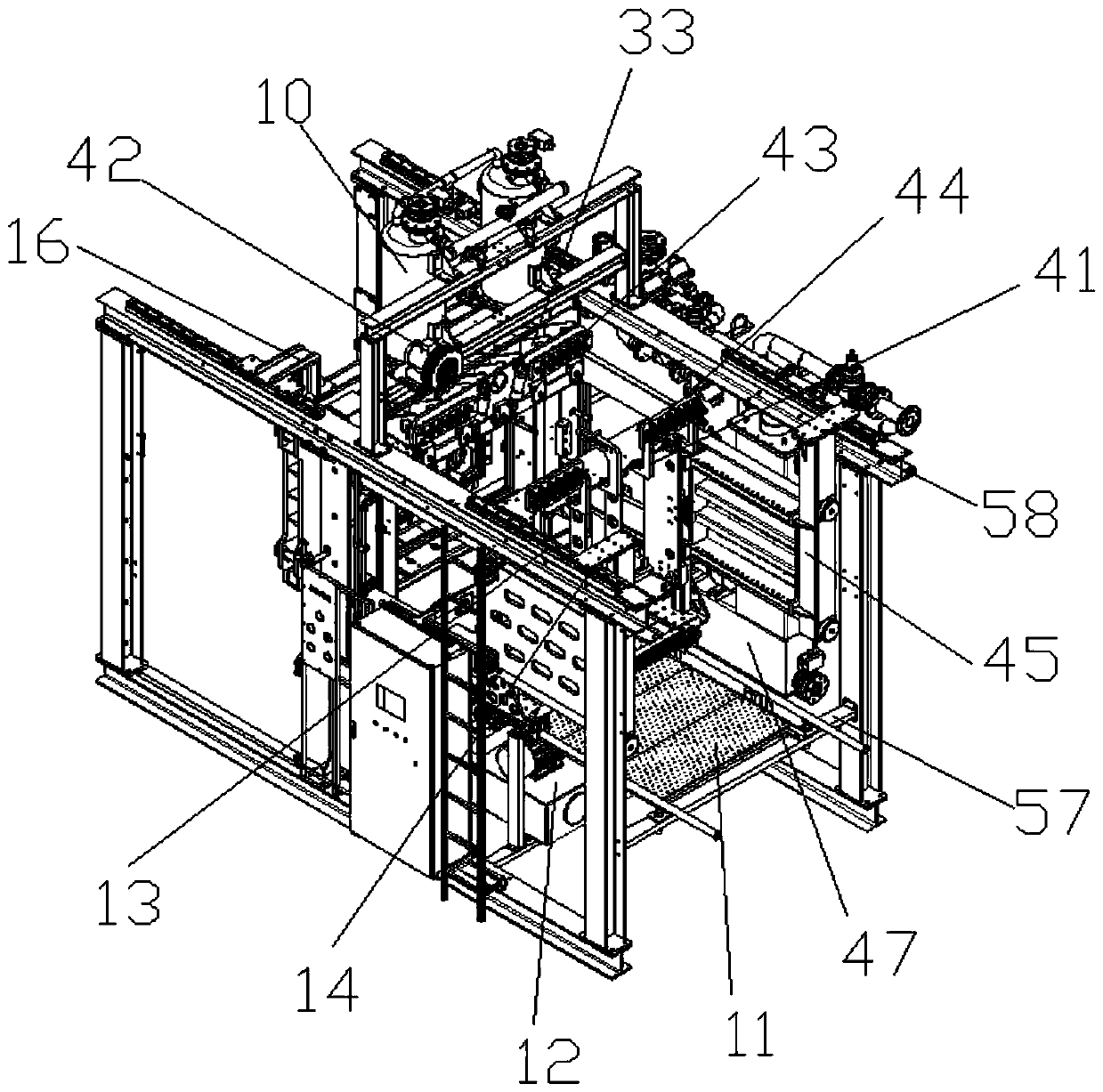

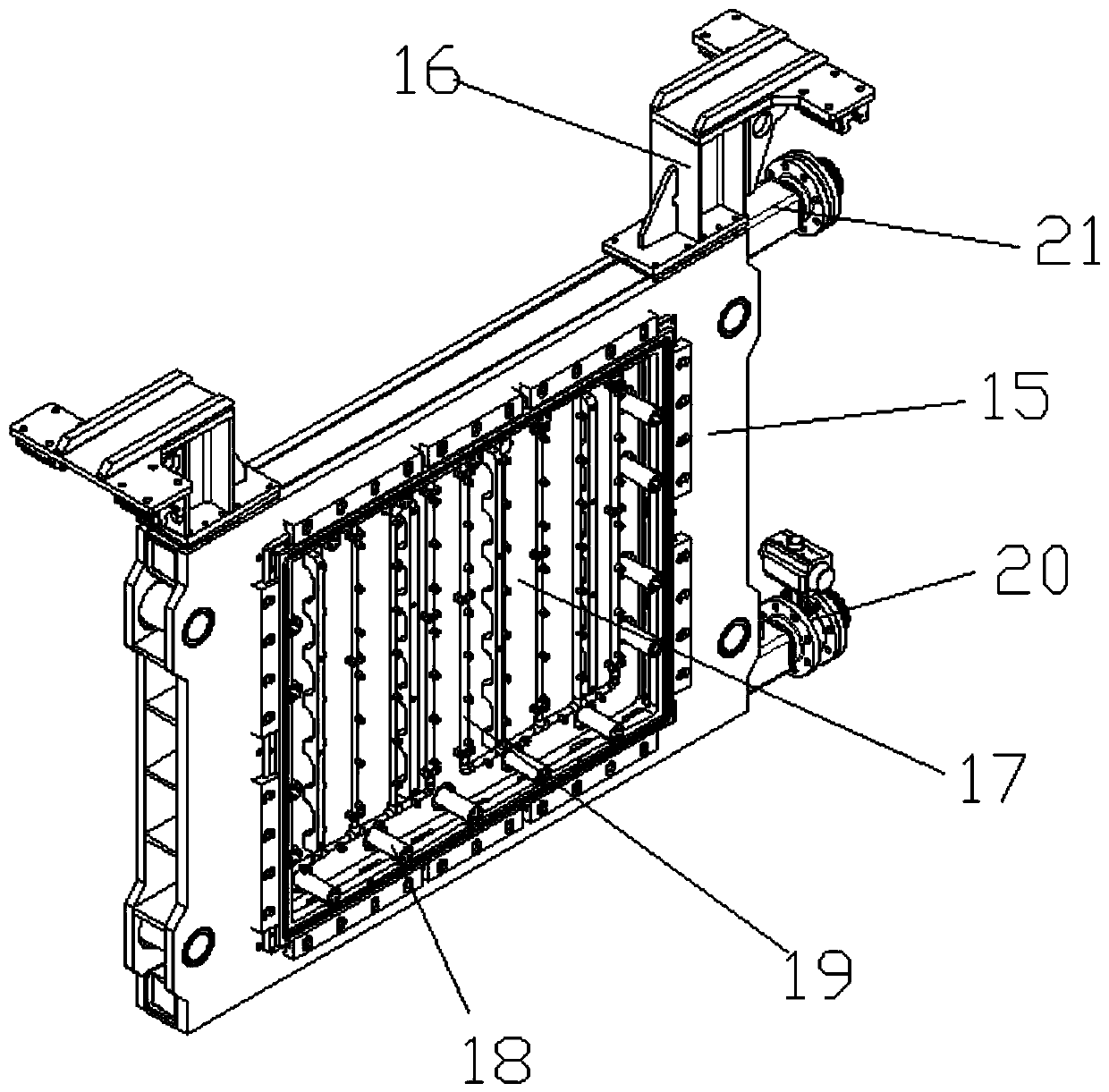

[0053] refer to Figure 1 to Figure 9 A new double-rod oil cylinder vacuum foam plastic hydraulic molding machine is shown, including a frame 1, an electric control cabinet 2, a protective net 3, an instrument panel 4, a stripping plate sliding part 5, a moving mold assembly 6, and a solid mold assembly 7 , mold frame 8, hydraulic oil tank 12, fast loading frame 45, condenser 47 and motor 54, motor 54 is installed on the hydraulic oil tank 12, and hydraulic oil tank 12 is arranged on the lower end of frame 1 inside, and the upper end of hydraulic oil tank 12 is provided with An anti-skid plate 11, the protective net 3 is arranged on both sides of the frame 1, the electric control cabinet 2 and the instrument panel 4 are installed on the frame 1, and the mold moving assembly 6 includes a mold moving frame 15, a mold moving slider The connecting plate 16 and the mold-moving heat insulation board 17, one side of the mold-moving mold frame 15 is provided with a mold-moving intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com