Preparation method for synthesizing photo-catalytic material by using MOF as precursor

A catalytic material and synthetic light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of stable material structure, simple process operation, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

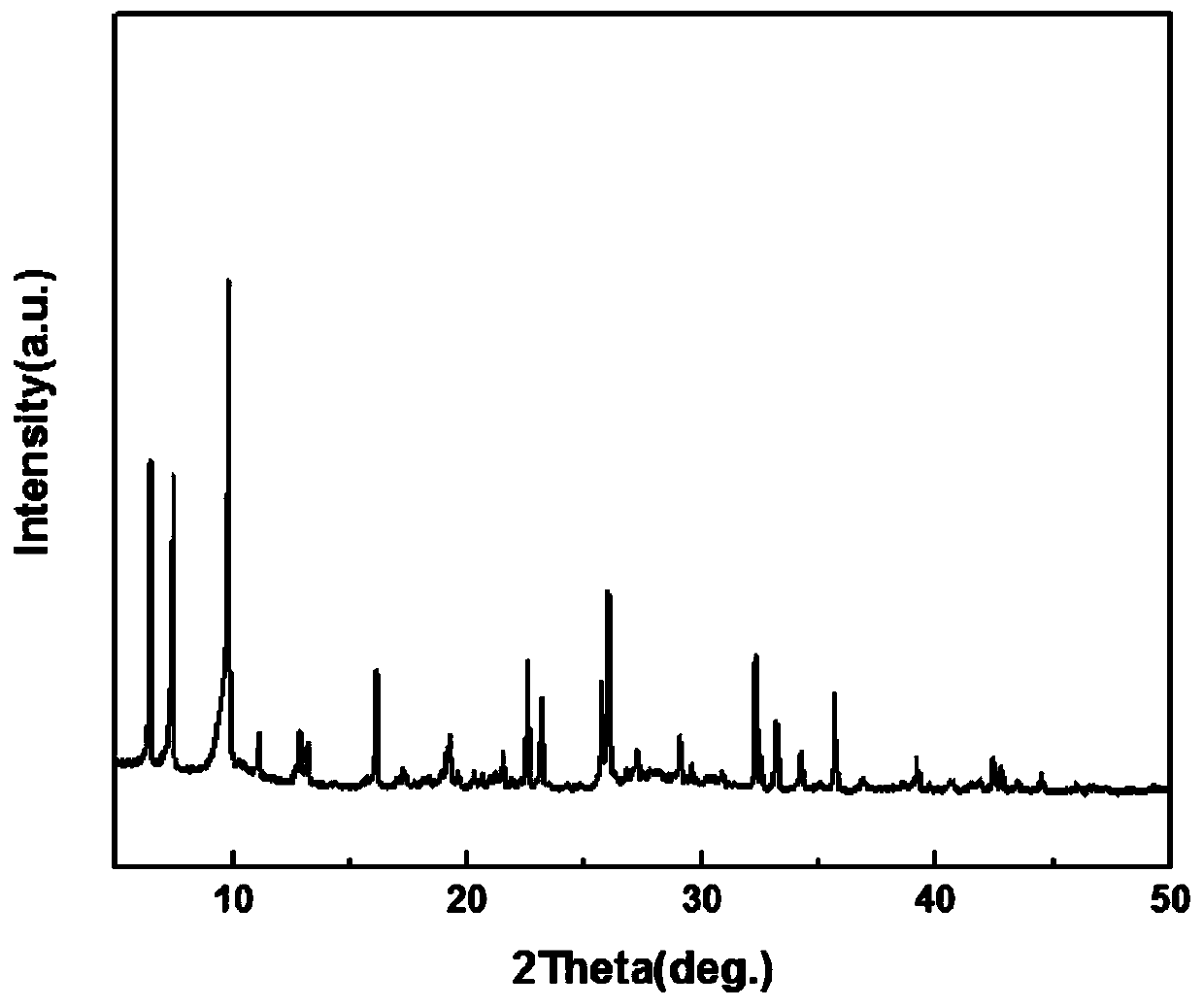

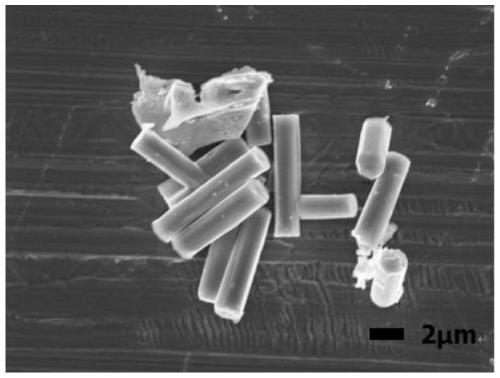

[0050] At 25°C, weigh 1.5g terephthalic acid (H 3 BTC), take a clean beaker, measure 60mL of anhydrous methanol, then add the weighed drug into it, put it into an ultrasonic machine to ultrasonically disperse the drug in the anhydrous methanol solution, mix and stir until completely dissolved, and wait for the solution After dissolving evenly, weigh bismuth nitrate pentahydrate (0.3g) into the beaker, stir evenly, after the solution is uniformly dissolved, pour the same amount into several reaction kettles, then put the reaction kettles into a water heating tank, and react at 120°C for 24h . After the reaction was completed, the product was centrifuged at 10000r / min for 5 minutes, and then dried in an oven at 60°C for 12 hours to finally obtain the BiMOF material, whose x-ray powder diffraction pattern ( figure 1 ) is shown as the characteristic diffraction peak of CAU-17, scanning electron micrograph ( figure 2 ) shows that the material exhibits a rod-like morphology. Wei...

Embodiment 2

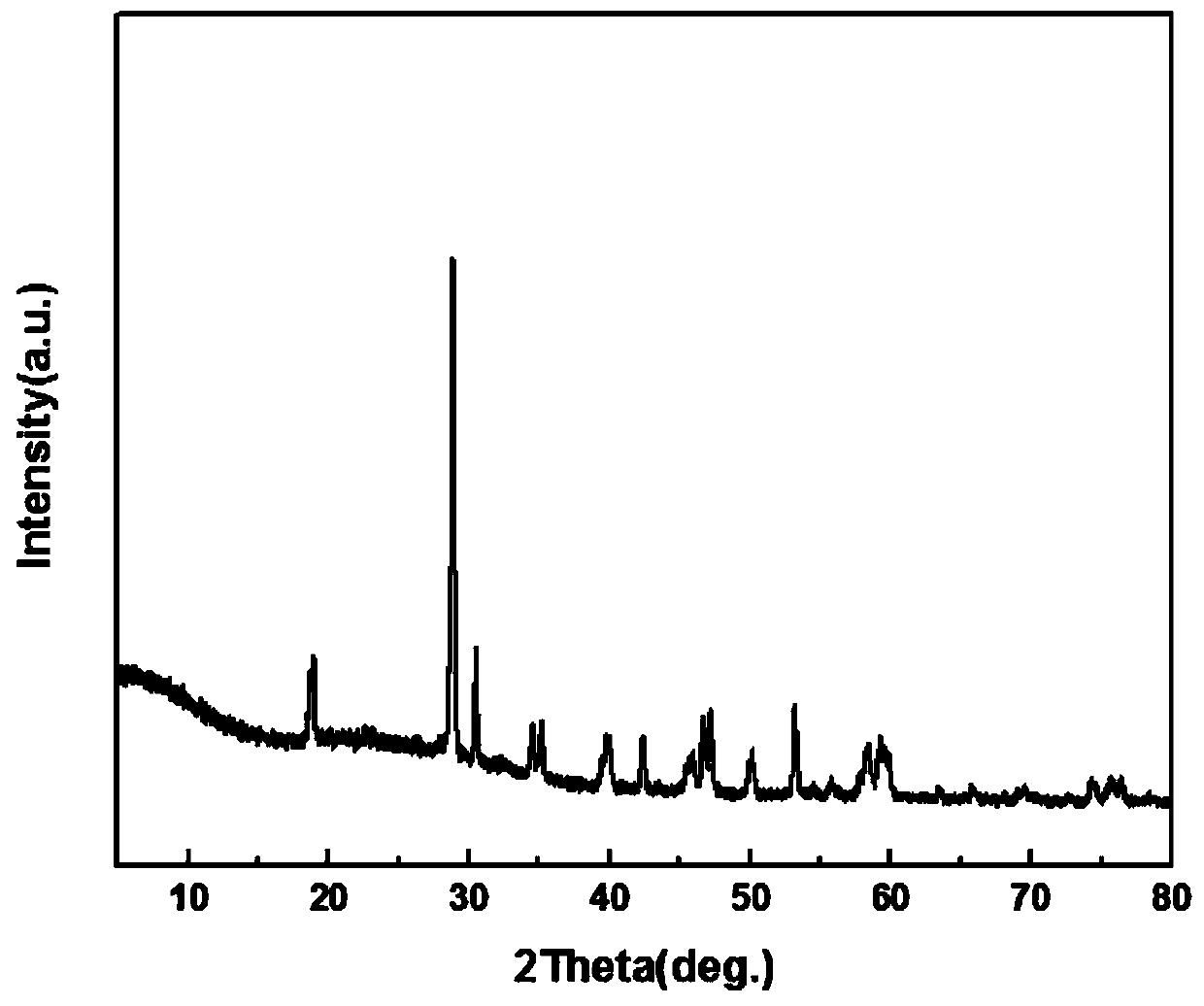

[0052] At 25°C, weigh 1.5g terephthalic acid (H 3 BTC), take a clean beaker, measure 60mL of anhydrous methanol, then add the weighed drug into it, put it into an ultrasonic machine to ultrasonically disperse the drug in the anhydrous methanol solution, mix and stir until completely dissolved, and wait for the solution After dissolving evenly, weigh bismuth nitrate pentahydrate (0.3g) into the beaker, stir evenly, after the solution is uniformly dissolved, pour the same amount into several reaction kettles, then put the reaction kettles into a water heating tank, and react at 120°C for 24h . After the reaction was completed, the product was centrifuged at 10,000 r / min for 5 minutes, and dried in an oven at 60°C for 12 hours to finally obtain the BiMOF material. Weigh 0.2216g ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 ·xH 2 0), take a clean beaker, measure 50mL of deionized water, add the weighed medicine into it, stir in a 60°C water bath until clarification, weigh...

Embodiment 3

[0054] At 25°C, weigh 1.5g terephthalic acid (H 3 BTC), take a clean beaker, measure 60mL of anhydrous methanol, then add the weighed drug into it, put it into an ultrasonic machine to ultrasonically disperse the drug in the anhydrous methanol solution, mix and stir until completely dissolved, and wait for the solution After dissolving evenly, weigh bismuth nitrate pentahydrate (0.3g) into the beaker, stir evenly, after the solution is uniformly dissolved, pour the same amount into several reaction kettles, then put the reaction kettles into a water heating tank, and react at 120°C for 24h . After the reaction was completed, the product was centrifuged at 10,000 r / min for 5 minutes, and dried in an oven at 60°C for 12 hours to finally obtain the BiMOF material. Weigh 0.5308g ammonium molybdate tetrahydrate (H 32 Mo 7 N 6 o 28 ), take a clean beaker, measure 50mL of deionized water, add the weighed drug into it, stir in a 60°C water bath until clear, weigh 0.5022g of the B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com