Carbon-based asymmetric naphthalene-containing double-crown supramolecular hybrid material, and preparation method and application thereof

A hybrid material, asymmetric technology, applied in chemical instruments and methods, radioactive purification, other chemical processes, etc., can solve the problems of poor radiation resistance and chemical stability, decreased saturation capacity, large equipment scale, etc., to achieve radiation resistance. The effect of strong chemical stability, large capacity and distribution coefficient, and high distribution coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

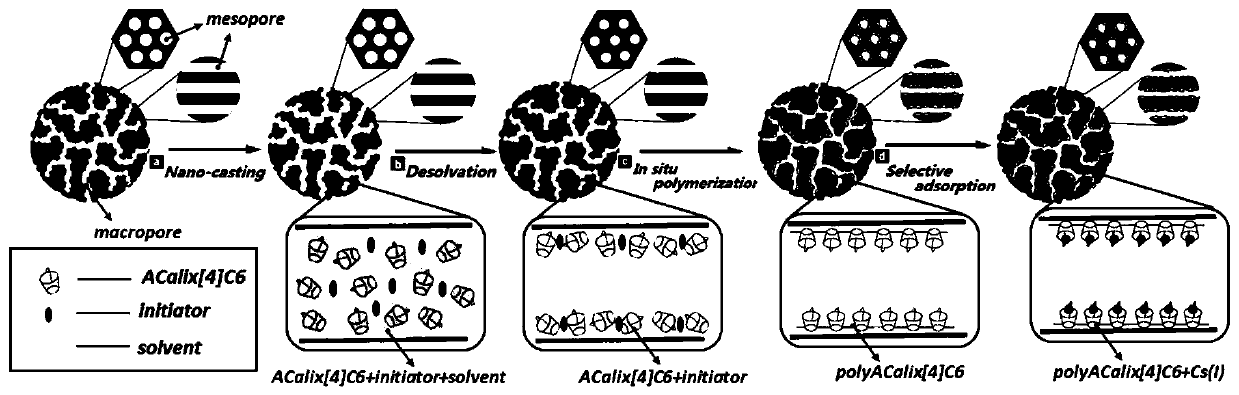

[0096] The embodiment of the present invention discloses a preparation method of a carbon-based asymmetric naphthobicrown-containing supramolecular hybrid material, which specifically includes the following steps:

[0097] (1) Synthesize tert-butyl calix[4]arene first, and then synthesize calix[4]arene from tert-butyl calix[4]arene

[0098] (a) Synthesis of tert-butylcalix[4]arene

[0099] Put 40-60g of tert-butylphenol, 35-45mL of 10-15mol / L formaldehyde aqueous solution and 1.0-1.5g of sodium hydroxide into a three-necked flask under the condition of 15-25°C, and add diphenyl ether solvent, Introduce argon, and dissolve the tert-butylphenol under the heating condition of 30-50°C, then raise the temperature to 90-100°C and heat to reflux for 0.5-2h, and continue to heat up to 105-115°C and heat to reflux for 2-3h;

[0100] Next, after the reaction was completed, the water in the reaction system was distilled off with nitrogen gas, then 600-1000 mL of ethyl acetate was added ...

Embodiment 1

[0128] Embodiment 1 of the present invention discloses a preparation method of a carbon-based asymmetric naphthobicrown-containing supramolecular hybrid material, which specifically includes the following steps:

[0129] (1) Synthesize tert-butyl calix[4]arene first, and then synthesize calix[4]arene from tert-butyl calix[4]arene

[0130] (a) Synthesis of tert-butylcalix[4]arene

[0131] Put 40g of tert-butylphenol, 35mL of 10mol / L aqueous formaldehyde solution and 1.0g of sodium hydroxide into a three-necked flask at 15°C, add diphenyl ether solvent, pass in argon, and heat at 30°C Dissolve tert-butylphenol under certain conditions, then heat up to 90°C and heat to reflux for 0.5h, then continue to heat up to 105°C and heat to reflux for 2h;

[0132] Then, after the reaction was completed, the water in the reaction system was distilled off with nitrogen, and then 600 mL of ethyl acetate was added and stirred for 0.5 h, and finally tert-butyl-calix[4]arene was obtained after ...

Embodiment 2

[0160] Embodiment 2 of the present invention discloses a preparation method of a carbon-based asymmetric naphthobicrown-containing supramolecular hybrid material, which specifically includes the following steps:

[0161] (1) Synthesize tert-butyl calix[4]arene first, and then synthesize calix[4]arene from tert-butyl calix[4]arene

[0162] (a) Synthesis of tert-butylcalix[4]arene

[0163] At 25°C, put 60g of tert-butylphenol, 45mL of 15mol / L aqueous formaldehyde and 1.5g of sodium hydroxide into a three-necked flask, add diphenyl ether solvent, pass in argon, and heat at 50°C Dissolve tert-butylphenol under certain conditions, then heat up to 100°C and heat to reflux for 2 hours, then continue to heat up to 115°C and heat to reflux for 3 hours;

[0164] Then, after the reaction was completed, the water in the reaction system was distilled off with nitrogen, and then 1000 mL of ethyl acetate was added and stirred for 1.0 h, and finally tert-butyl-calix[4]arene was obtained afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com