Quick-solidification anti-collapse dental filling material

A dental filling material and rapid curing technology, applied in dentistry, dental preparations, dental prostheses, etc., can solve the problems of increasing the number of patient visits, increasing the risk of oral tissue, and easy dissociation of solid particles, so as to improve the efficacy of root canal treatment, Excellent apatite forming ability and the effect of improving the erosion ability of foreign liquid phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 4.5g of tricalcium silicate powder and 0.5g of disodium hydrogen phosphate, and mix them uniformly; weigh 0.1g of polycarboxylic acid and dissolve in 9.9g of deionized water to obtain a blend solution. Then fully blend the solid phase powder and liquid phase at a liquid-solid ratio of 0.5, inject the mold into the mold, and obtain the filling material and maintain it at 37°C.

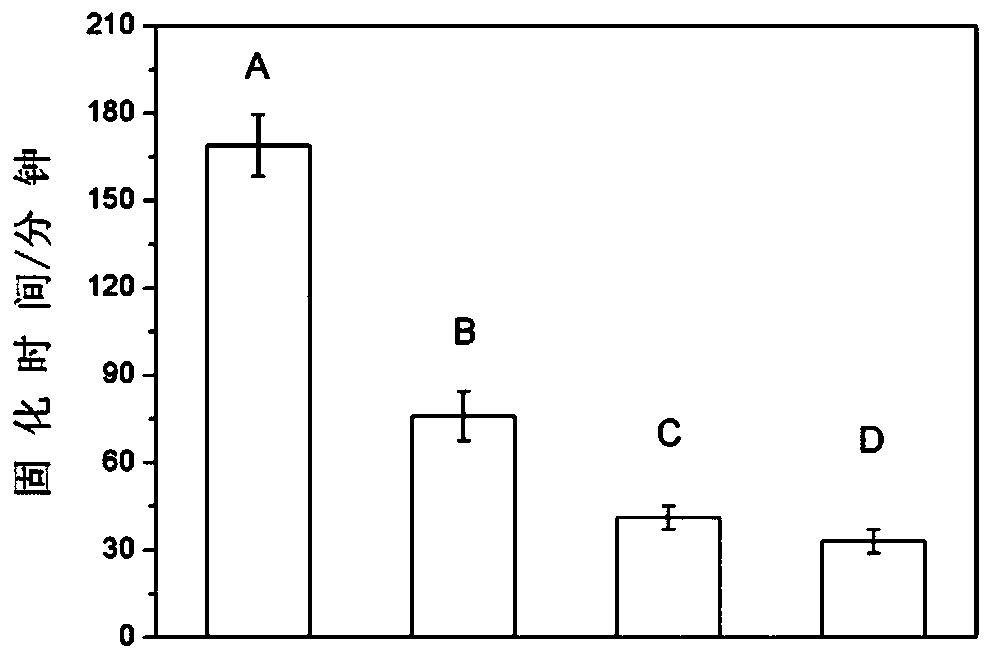

[0037] The solidification time of the composite slurry was measured by a penetrometer, and the results were as follows: figure 1 Shown in B, compared with comparative example 1, the curing time of composite slurry is reduced to 76 minutes by 169 minutes of comparative example, and this result shows that introducing disodium hydrogen phosphate can significantly reduce the curing time of this composite material.

Embodiment 2

[0039] Weigh 4g of tricalcium silicate powder and 1g of disodium hydrogen phosphate, and mix them uniformly; weigh 0.05g of polycarboxylic acid and dissolve in 4.95g of deionized water to obtain a blended solution. Then fully blend the solid phase powder and liquid phase at a liquid-solid ratio of 0.5, inject the mold into the mold, and obtain the filling material and maintain it at 37°C.

[0040] The solidification time of the composite slurry was measured by a penetrometer, and the results were as follows: figure 1 Shown in C, compared with comparative example 1, the solidification time of composite slurry is reduced to 41 minutes by 169 minutes of comparative example, and this result shows that introducing disodium hydrogen phosphate can significantly reduce the solidification time of this composite material.

[0041] Prepare the newly prepared composite paste slurry into a circular sample block, and then soak it in the liquid phase to observe whether the composite slurry c...

Embodiment 3

[0043] Weigh 3.5g of tricalcium silicate powder and 1.5g of disodium hydrogen phosphate, and mix them uniformly; weigh 0.04g of polycarboxylic acid and dissolve in 3.96g of deionized water to obtain a blend solution. Then fully blend the solid phase powder and liquid phase at a liquid-solid ratio of 0.5, inject the mold into the mold, and obtain the filling material and maintain it at 37°C.

[0044] The solidification time of the composite slurry was measured by a penetrometer, and the results were as follows: figure 1 As shown in D, compared with Comparative Example 1, the curing time of the composite slurry was reduced from 169 minutes to 33 minutes. This result shows that the introduction of disodium hydrogen phosphate can significantly reduce the curing time of the composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com