In-service air cooler tube bundle detection method based on X-ray digital imaging technology

A digital imaging and detection method technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of insufficient detection effect, high detection condition requirements, and inability to effectively detect tube bundles, etc., so as to facilitate project quality management and avoid abnormal Planned downtime, the effect that is conducive to safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

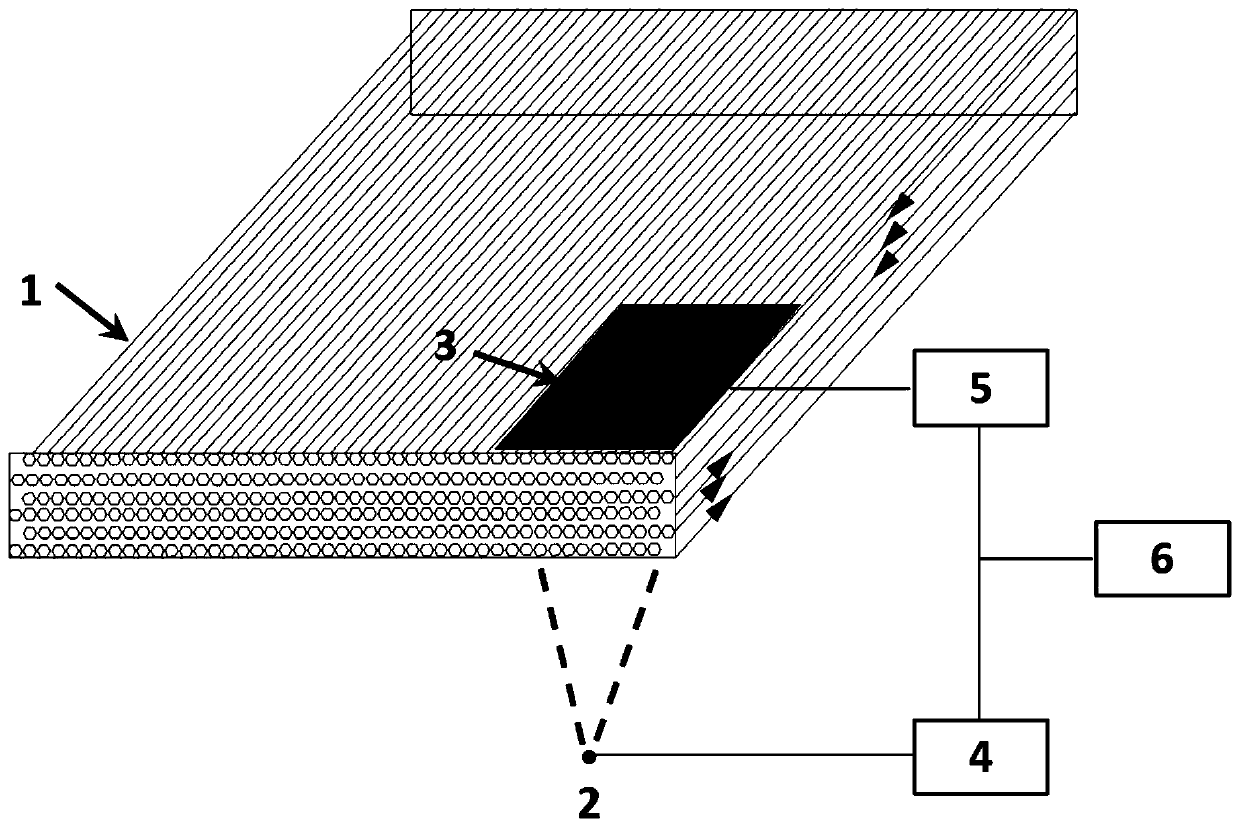

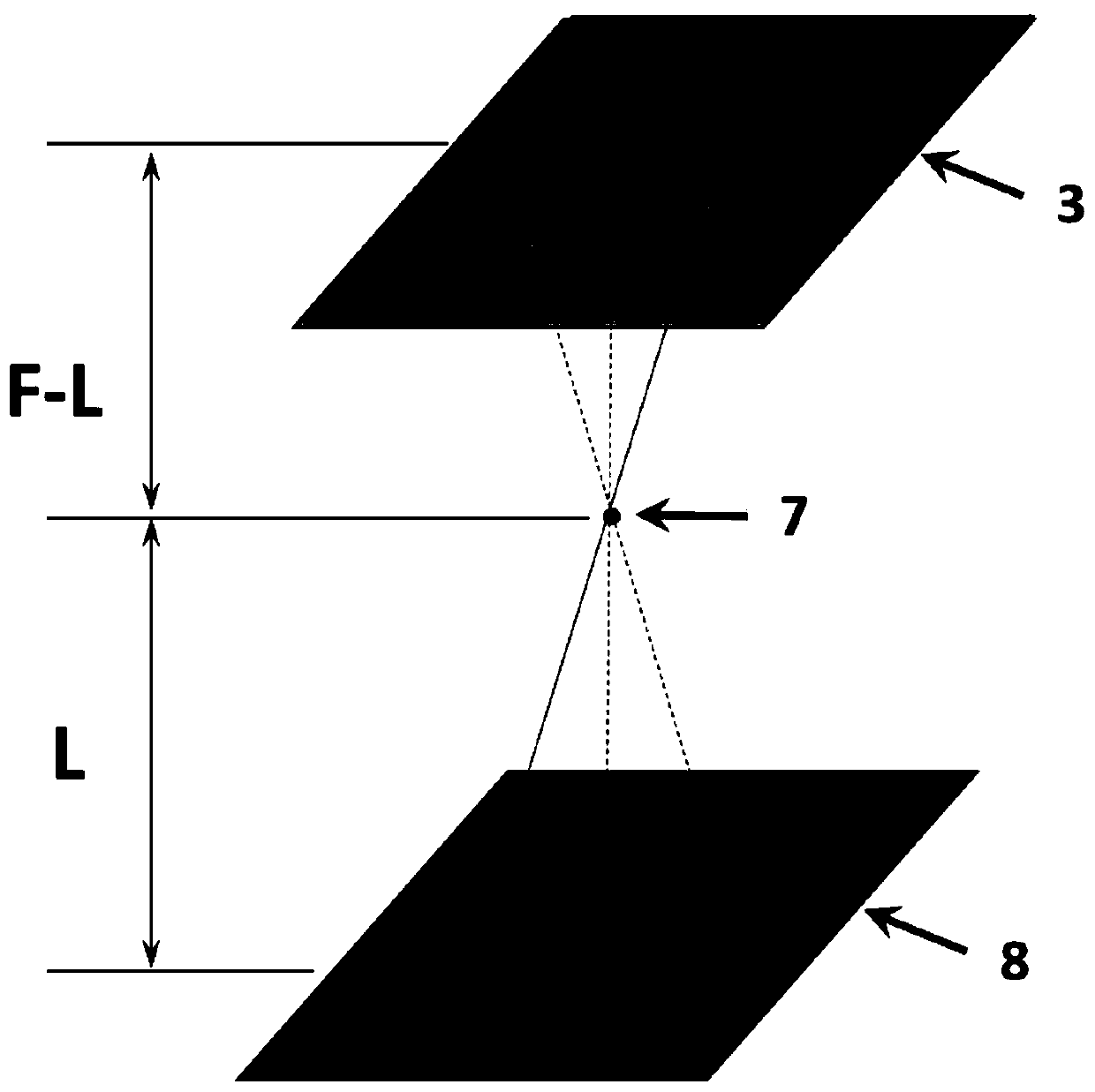

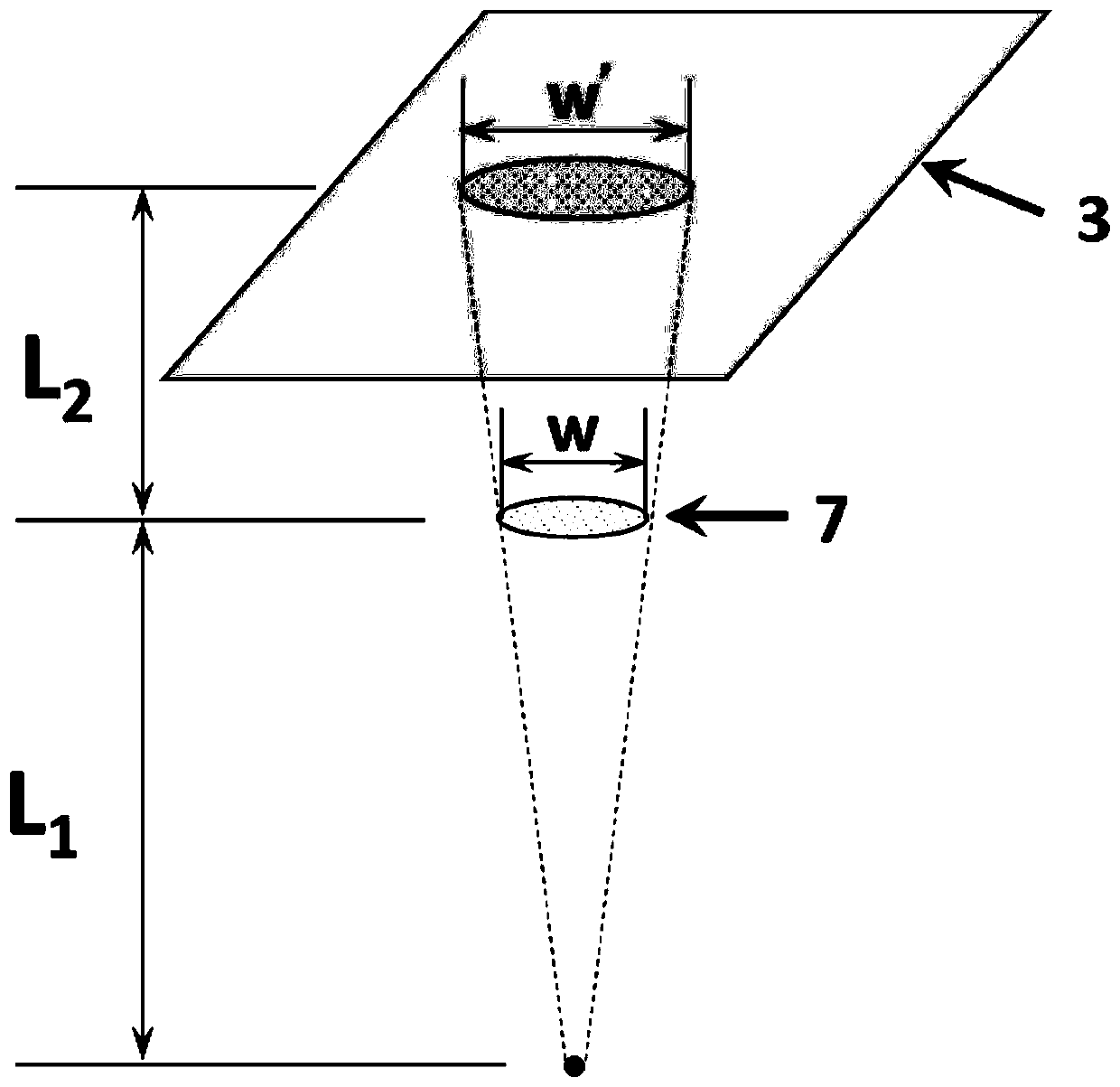

[0055] The method for detecting tube bundles of in-service air coolers based on the X-ray digital imaging technology of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0056] The detection method of the in-service air cooler tube bundle based on X-ray digital imaging technology of the present invention uses X-ray digital imaging technology to detect the tube bundle of the air cooler, and the detection equipment and supplies in the embodiment of the invention include an X-ray machine (MRXD-300 (directional) , high-frequency constant voltage, focus 2.2×2.6), flat-panel detector 14×17in, control box, wire controller, computer, tooling, safety protection products and other inspection supplies.

[0057] The detection method of the in-service air cooler tube bundle based on X-ray digital imaging technology of the present invention comprises the following steps:

[0058] 1) Determine the test object, prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com