Automatic shutdown method of electric towing turbine unit in failure of controlling system and oil system

A turbine unit and oil system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as failure of the lubricating oil system, failure of the unit to automatically stop immediately, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

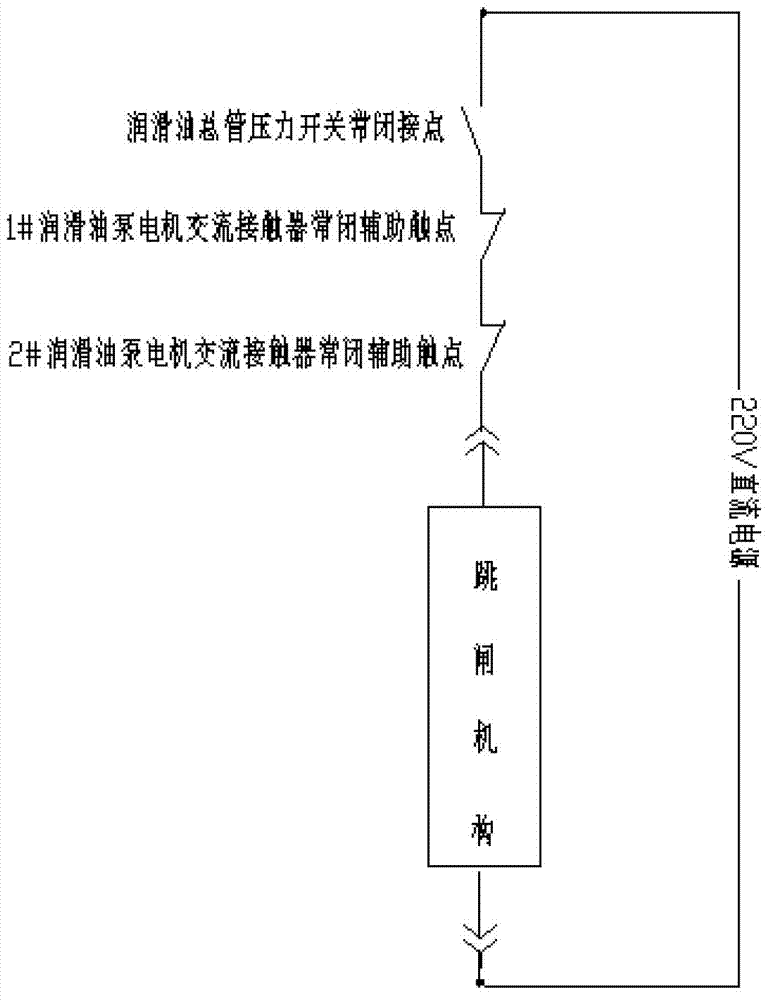

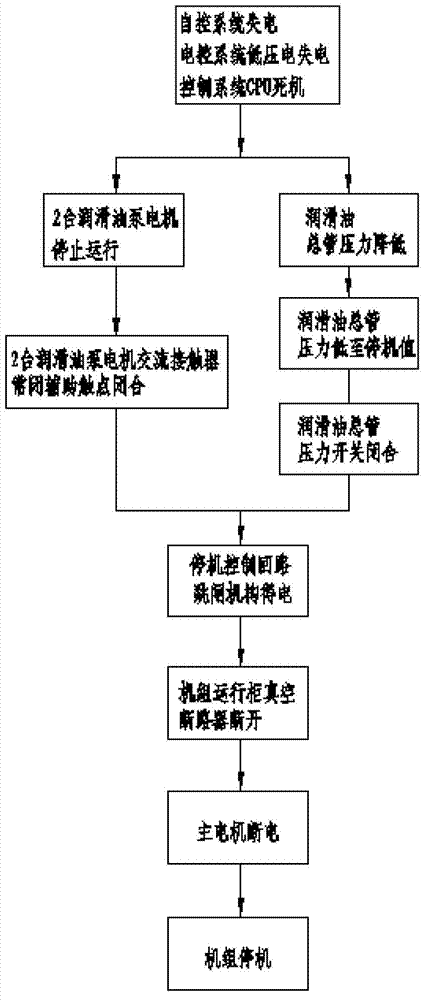

[0017] For a conventional motor-driven turbocompressor unit, the lubricating oil system is usually provided with two mutual main and backup lubricating oil pumps (1# lubricating oil pump, 2# lubricating oil pump). The method of the present invention is to include 1# lubricating oil pump , The motor of the 2# lubricating oil pump drives the turbine compressor unit as the object. refer to figure 1 , the automatic shutdown method of the motor-driven turbine unit of the present invention when the control system and the oil system fail, specifically includes the following steps:

[0018] The first step is to set a normally open pressure switch on the lubricating oil supply main pipe of the motor-driven turbine unit farthest from the unit, and set the lubricating oil shutdown pressure setting value according to the actual operating conditions of the unit (generally set is 80KPa), when the lubricating oil pressure is lower than the set value, the pressure switch contact is closed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com