Controllable phase change material bag and preparation method and application thereof

A technology of phase change materials and seed crystals, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of difficult heat storage and release, and achieve a simple, controllable and easy-to-operate preparation method , short production cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

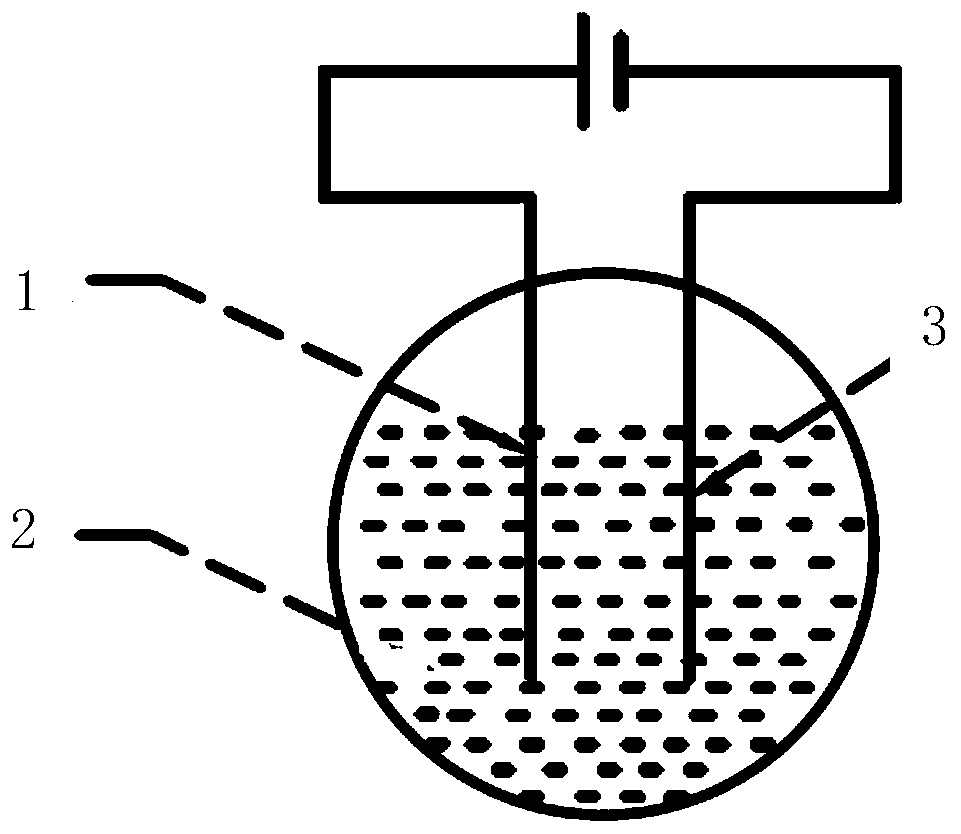

[0030] The preparation of the controllable phase change material package comprises the following steps:

[0031] (1) Take the sodium acetate trihydrate crystal and place it in a mortar and grind it into powder for use; take the silver wire electrode, polish the surface with 80-mesh sandpaper, and coat the ground powder on the surface; then polish the surface with 320-mesh sandpaper, The surface is coated with powder; the surface is polished again with 1200 mesh sandpaper, and then coated with a layer of sodium acetate trihydrate powder, and the electrode carrying the powder seed crystal is placed in a sodium acetate solution at 75°C for 2 hours in a water bath to obtain a controllable trigger metal electrode 1;

[0032] (2) In terms of mass fraction, weigh 82.2% of sodium acetate trihydrate crystals, 16.8% of water, and 1% of carboxymethylcellulose into a beaker, stir in a water bath at 75°C until completely dissolved, and obtain a supersaturated phase Change heat storage solu...

Embodiment 2

[0035] The preparation of the controllable phase change material package comprises the following steps:

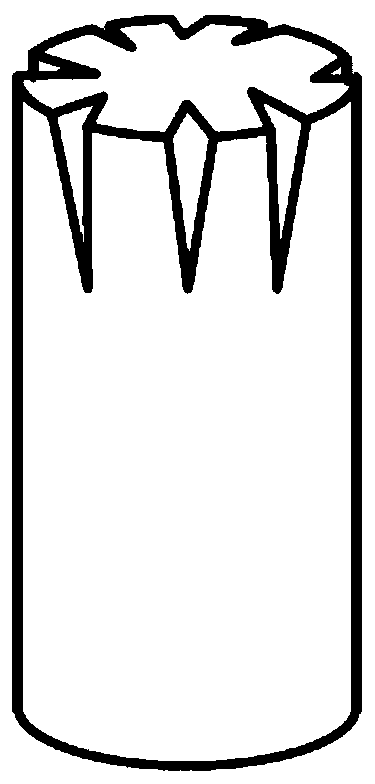

[0036] (1) Take the sodium acetate trihydrate crystal and place it in a mortar and grind it into powder for later use; take the copper wire electrode, draw a scratch on the end of the electrode with a knife, and apply the ground powder to the scratch on the end of the copper wire rod, Then place the metal electrode in a sodium acetate solution and keep it warm in a 70°C water bath for 1 hour to obtain a controllable trigger metal electrode, as shown in figure 2 shown;

[0037] (2) Weigh 91% of sodium acetate trihydrate, 8.5% of water, and 0.5% of carboxymethyl cellulose in terms of metering fractions, and stir in a water bath at 80°C until completely dissolved to obtain a supersaturated phase-change heat storage solution. Pour the prepared solution into a stainless steel ball while it is hot, then insert the above-mentioned pretreated electrode and graphite rod electrode...

Embodiment 3

[0040] The preparation of the controllable phase change material package comprises the following steps:

[0041] (1) Take the sodium acetate trihydrate crystal and place it in a mortar and grind it into powder for use; take the silver wire electrode, scratch the end of the electrode with a knife, and coat the ground powder on the end of the silver wire rod to scratch, Then place the silver wire electrode in a sodium acetate solution and keep it in a 75°C water bath for 2 hours to obtain a controllable trigger metal electrode;

[0042] (2) In terms of measured fractions, weigh 73.5% of sodium acetate trihydrate, 24.5% of water, and 2% of sodium polyacrylate, and stir in a water bath at 70°C until completely dissolved to obtain a supersaturated phase-change heat storage solution. Pour the prepared solution into a stainless steel ball while it is hot, then insert the above-mentioned pretreated electrode and graphite rod electrode into the supersaturated phase change heat storage so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com