Modular cage type fresh air unit and fresh air processing method

A fresh air unit, modular technology, applied in the field of ventilation, can solve the problems of large overall volume, difficulty in transportation and installation, etc., and achieve the effects of small volume, convenient upgrade and replacement, and convenient structure conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

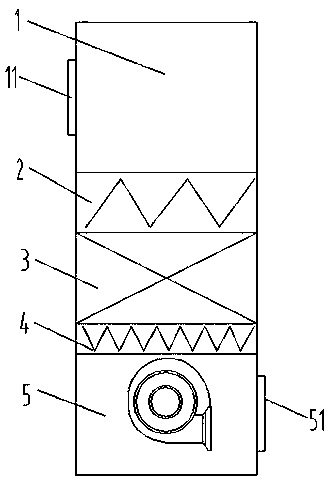

[0024] see figure 1 , figure 2 , a modular cage-type fresh air unit according to Embodiment 1, including independent air inlet box layers 1, first filter box layers 2, heat and humidity treatment box layers 3, and the Two filter box layers 4 and air supply box layers 5, the opposite faces of adjacent box layers are respectively provided with ventilation holes so as to communicate with each box layer one by one; the side walls of the air inlet box layer 1 are provided with The air inlet 11 is used to connect the air inlet pipe or directly introduce fresh air, and an air outlet 51 is opened on the side wall of the air supply box layer 5 to send out the treated fresh air.

[0025] In the fresh air unit of the present invention, two filter box layers are used to filter fresh air; the first filter box layer is used for preliminary filtration, and the existing primary filter filter can be selected or directly used in the box Used as the first filter box layer, the second filter b...

Embodiment 2

[0045] see image 3 The difference between a modular cage-type fresh air unit in Embodiment 2 and Embodiment 1 is that the orientation of stacking is upside down. Embodiment 2 is the air supply box layer 5 and the second filter box from bottom to top. Body layer 4, heat and humidity treatment box layer 3, first filter box layer 2, and air intake box layer 1; fresh air flows from top to bottom in the equipment, and is suitable for the form of down-supply or ground-supply air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com