A Large Pilot Ratio Hydraulic Control Check Valve

A hydraulically controlled one-way valve and pilot technology, applied in the direction of servo motor components, mechanical equipment, fluid pressure actuators, etc., can solve the problems of reducing the pressure of the control oil circuit, large impact force, high energy consumption, etc., to reduce hydraulic pressure, Effect of eliminating pressure difference and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

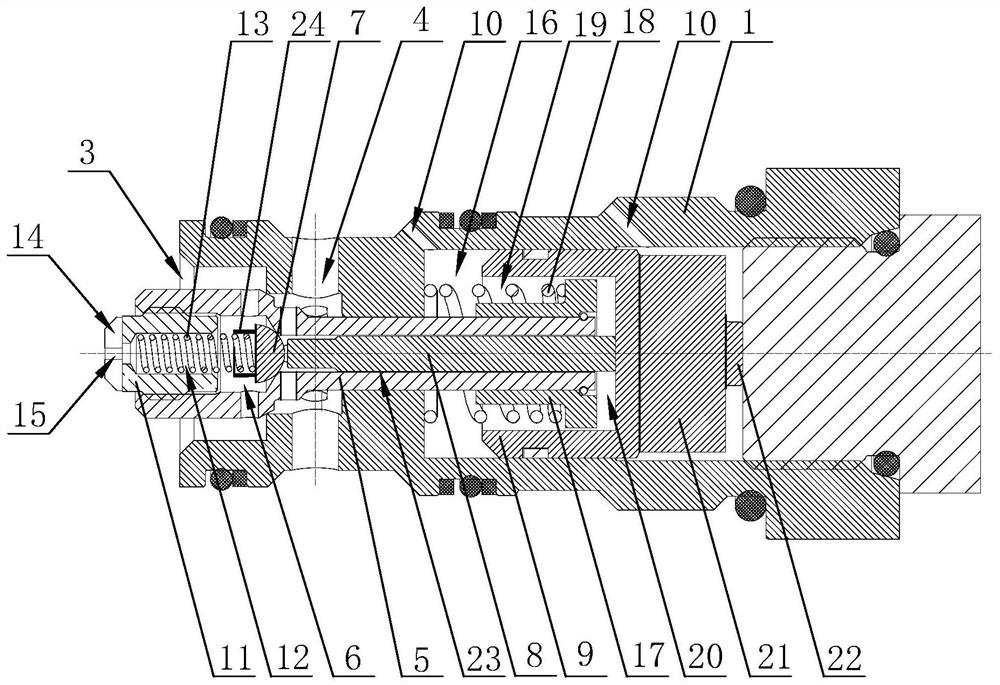

[0046] Such as figure 2 As shown, a large pilot ratio hydraulic control check valve differs from Embodiment 1 in that the spool 7 is in a hemispherical shape, and the arc surface of the spool 7 abuts against the opening of one end of the sliding groove 23, so that the sliding The opening of the shift groove 23 is closed, the flat surface of the spool 7 is connected to the clip spring 13, the side of the spool 7 near the clip spring 13 is integrally fixed with a limit ring 24, and one end of the clip spring 13 is plugged in the limit ring 24. Setting the valve core 7 in a hemispherical shape reduces the quality of the valve core 7 and improves the flexibility of the valve core 7 to control the on-off of the pressure relief passage 6 .

[0047] In summary:

[0048] When the present invention is used, the ejector rod 8 first pushes the valve core 7 to eliminate the pressure difference and reduce the thrust required to push the valve stem 5, thereby reducing the hydraulic pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com