Device and method for reducing and homogenizing residual stresses of complex component

A residual stress and component technology, applied in the field of residual stress reduction and homogenization devices for complex components, can solve problems such as high manufacturing cost and component surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

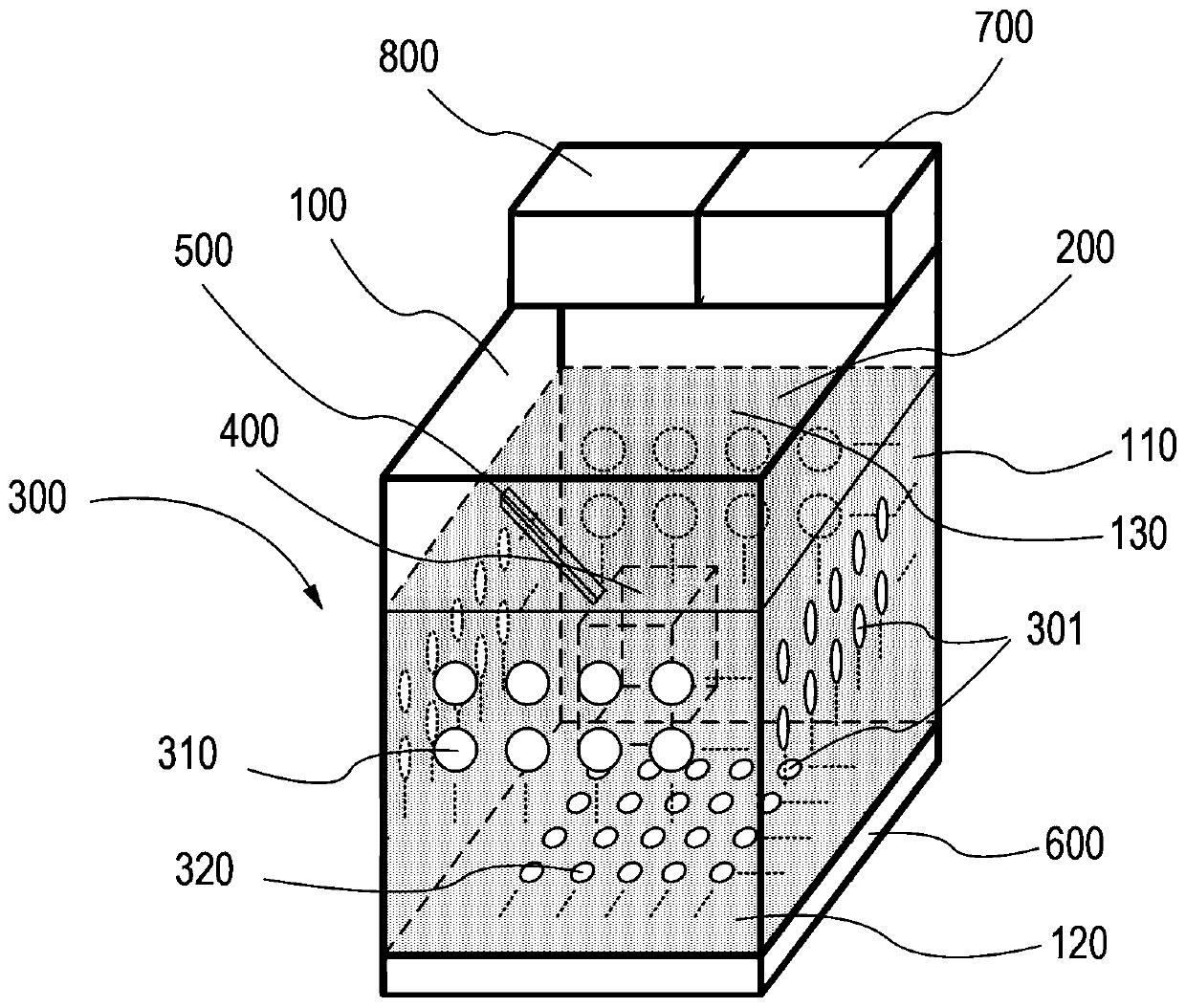

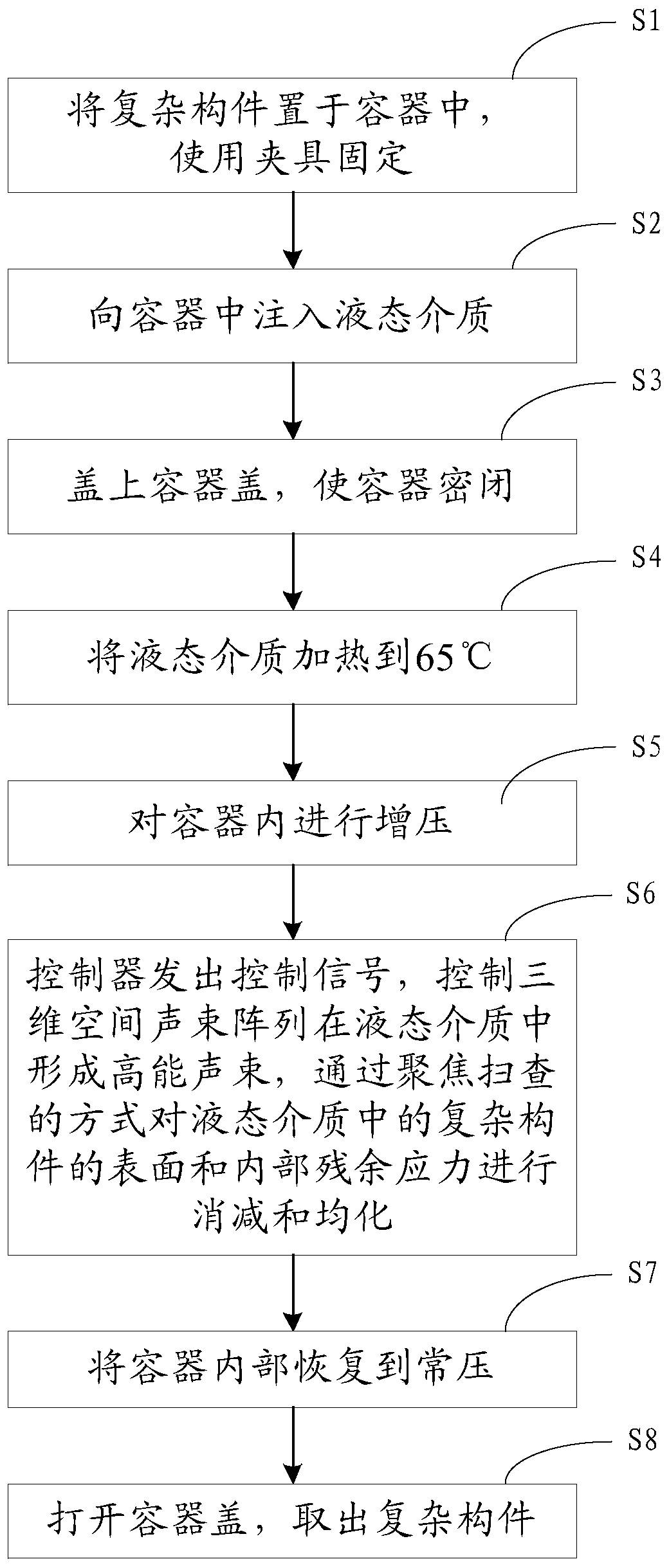

[0022] Such as figure 1 As shown, the embodiment of the present application provides a liquid space array high-energy acoustic beam focused scanning reduction and homogenization device for the residual stress of complex components. It includes a closed square tank pressure vessel 100 composed of a container wall 110, a container bottom 120, and a container cover 130; a liquid medium 200 is contained in the container 100; several high-energy ultrasonic transducers 301 installed on the container wall 110 and the container bottom 120, The transmitting end of the high-energy ultrasonic transducer 301 communicates with the interior of the container 100, and the high-energy ultrasonic transducer 301 is arrayed on the container wall 110 to form a first high-energy ultrasonic transducer array 310, and is aligned on the container bottom 120 to form a second high-energy ultrasonic transducer array. Transducer array 320, the first high-energy ultrasonic transducer array 310 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com