Low-bubble and low-dielectric glass fiber composition and its production process

A technology of glass fiber and production process, which is applied in the field of low-bubble and low-dielectric glass fiber composition and its production process, which can solve problems affecting work efficiency and achieve the effects of improving operating efficiency, saving raw materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

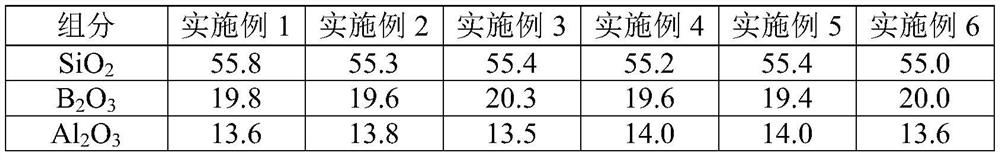

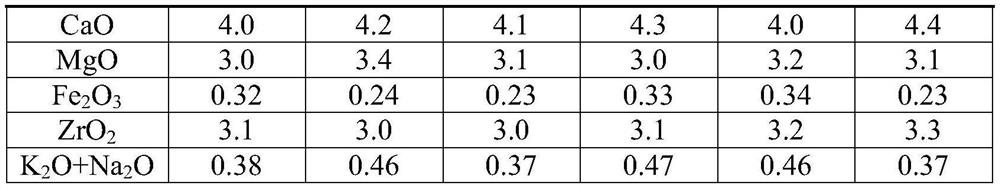

[0039] See Table 1 for the content data of each component of the low-bubble and low-dielectric glass fiber composition in Examples 1-6.

[0040] The low-bubble and low-dielectric glass fiber composition is made of the following raw materials: quartz powder, boric acid, limestone, magnesium oxide, kaolin, and zircon powder. See Table 2 and Table 3 for the particle size specific data of each raw material.

[0041] The production process of the described low-bubble and low-dielectric glass fiber composition comprises the following steps:

[0042] (1) Use mechanical mixing after weighing the raw materials according to the proportioning ratio, and mix the materials for 8 minutes to obtain a uniform batch;

[0043] (2) Using the electric boosting process to melt the batch materials;

[0044] (3) Wire drawing after melting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com