Flat wire material leveling and winding machine

A flat wire material and winding machine technology, which is applied in the direction of conveying filamentous materials, thin material processing, surface polishing machine tools, etc. Take it off and other problems to achieve the effect of good leveling quality, improved leveling quality, and firm shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

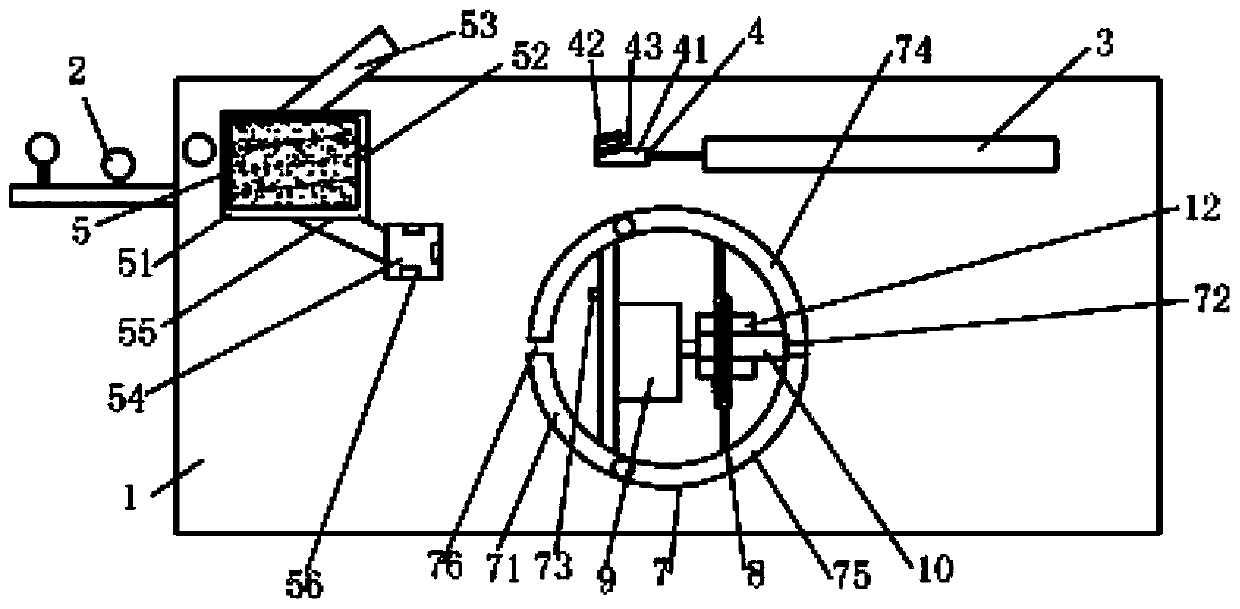

[0012] Combine below figure 1 Specific description embodiment:

[0013] The flat wire material flattening and winding machine includes a frame 1, and the frame 1 is provided with a leveling guide 2 and a straightening oil cylinder 3, and the output end of the straightening oil cylinder 3 is connected with a drawing hook 4. A leveling mechanism 5 is arranged on the frame 1 between the leveling guide 2 and the straightening oil cylinder 3. The leveling mechanism 5 includes an abrasive groove 51 filled with abrasive materials, and one side of the abrasive groove 51 is opened There is a port 52 for the flat wire material to pass through, and the port 52 and the straightening cylinder 3 are located at the same horizontal position. The head end of the flat wire material comes out from the port 52 and is connected to the drawing hook 4 and then passes through the straightening oil cylinder 3 Straightening; the top of the abrasive tank 51 is provided with a ramp 53, the place below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com