All-in-one shearing and packaging machine for plastic product

A technology of a plastic product and an all-in-one machine, applied in the direction of manufacturing tools, machine tools suitable for grinding the edges of workpieces, grinders, etc., can solve the problems of easy piercing of packaging bags, affecting the aesthetics of plastic products, etc., and achieve the effect of improving aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] see Figure 1-Figure 9 , the specific embodiments of the present invention are as follows:

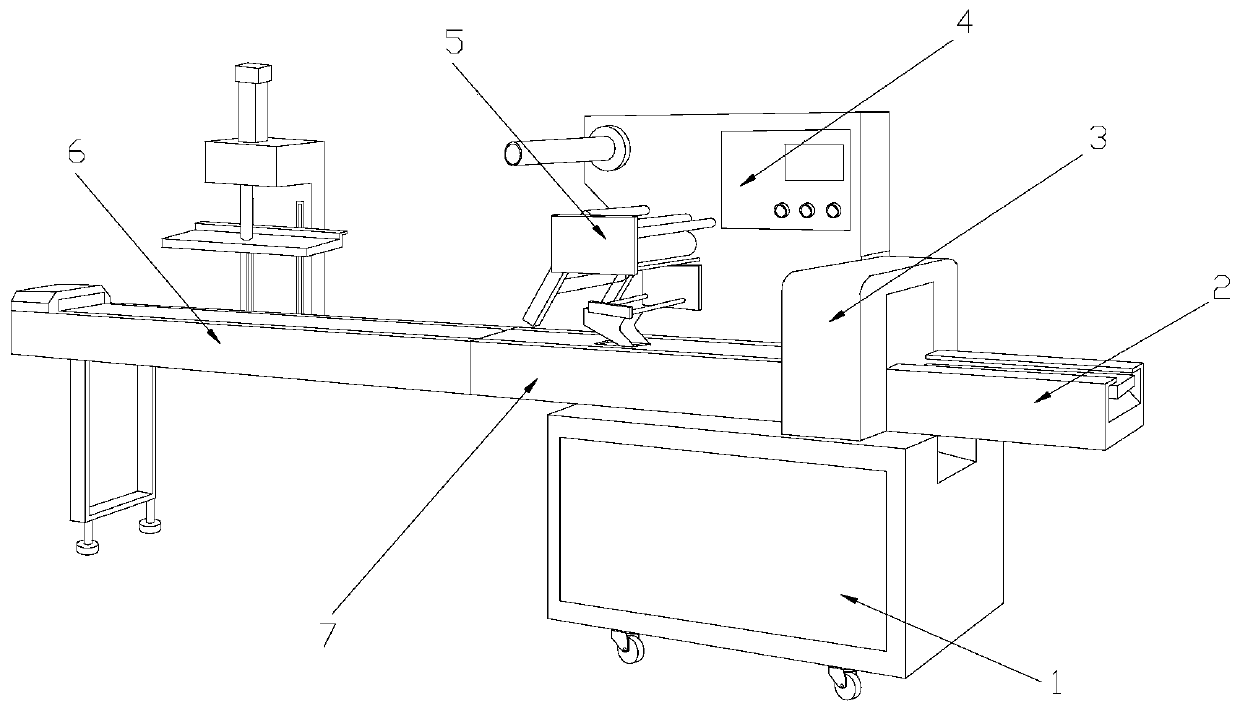

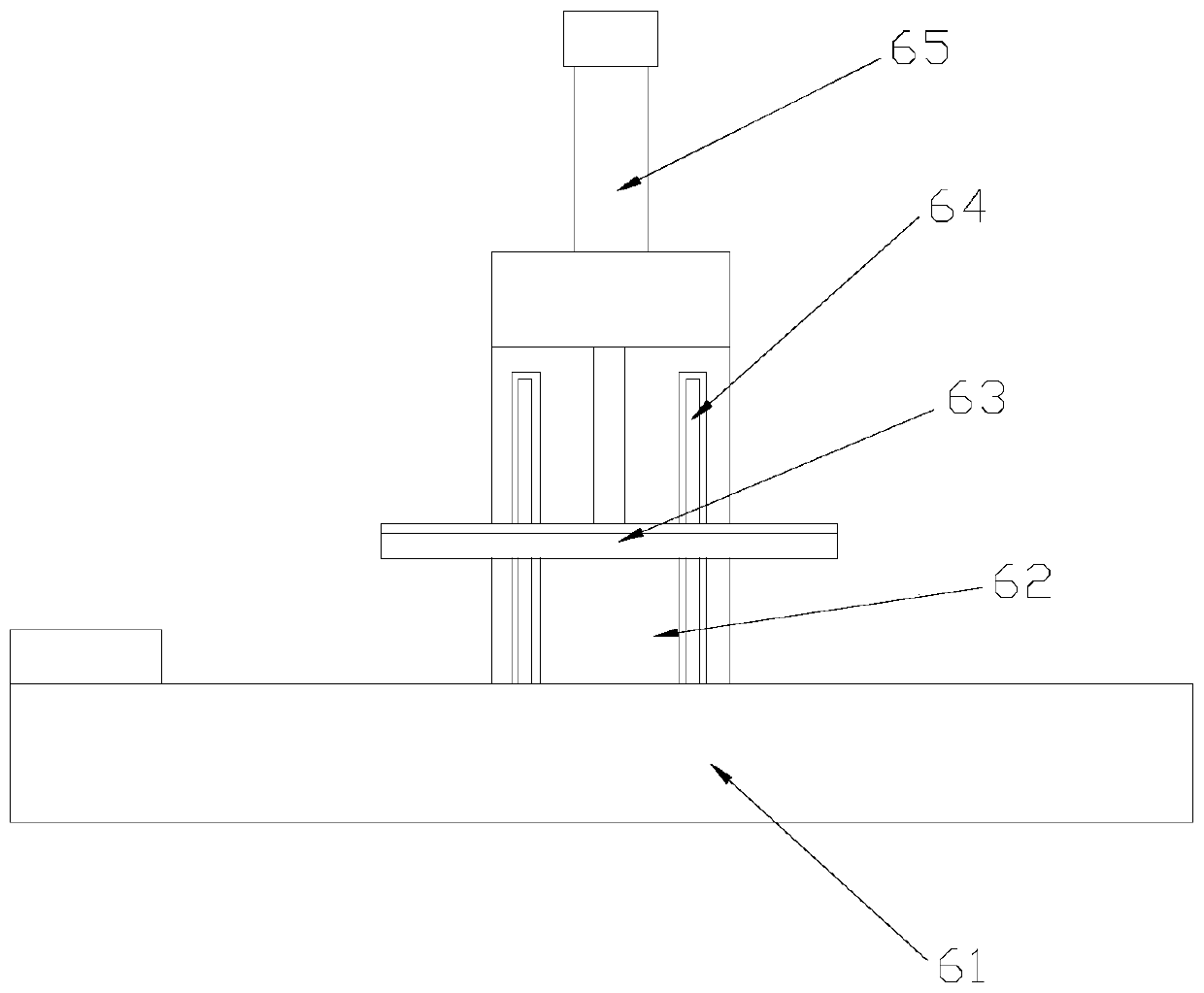

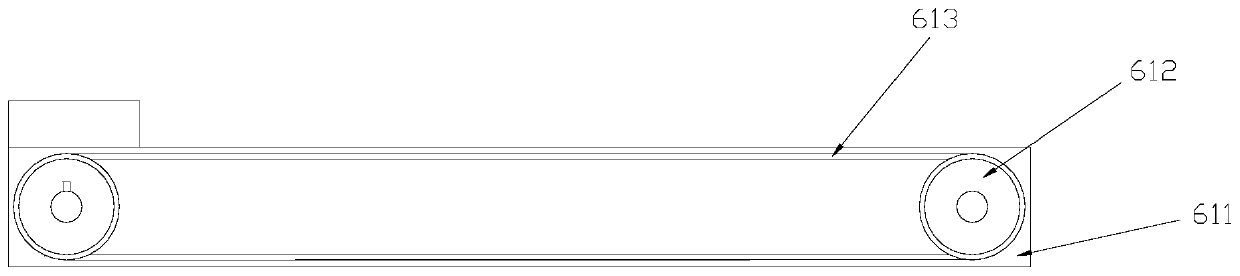

[0029] Its structure includes a box body 1, a discharge conveyor belt 2, a drying box 3, a control panel 4, a packaging machine 5, a shearing mechanism 6, and a conveyor belt 7. The box body 1 is horizontally installed at the lower end of the discharge conveyor belt 2, The drying box 3 is vertically installed on the upper end of the box body 1 and is arranged on the left side of the discharge conveyor belt 2, the lower end of the control panel 4 is connected with the upper end of the box body 1 by bolts, and the packaging machine 5 is arranged on the conveyor belt 7, the shear mechanism 6 is installed on the left side of the conveyor belt 7 and is located on the same level; Cylinder 65, the support beam 62 is vertically installed on the back of the sunken shearing conveying mechanism 61 and connected with bolts, the pressing mechanism 63 is horizontally installed on the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com