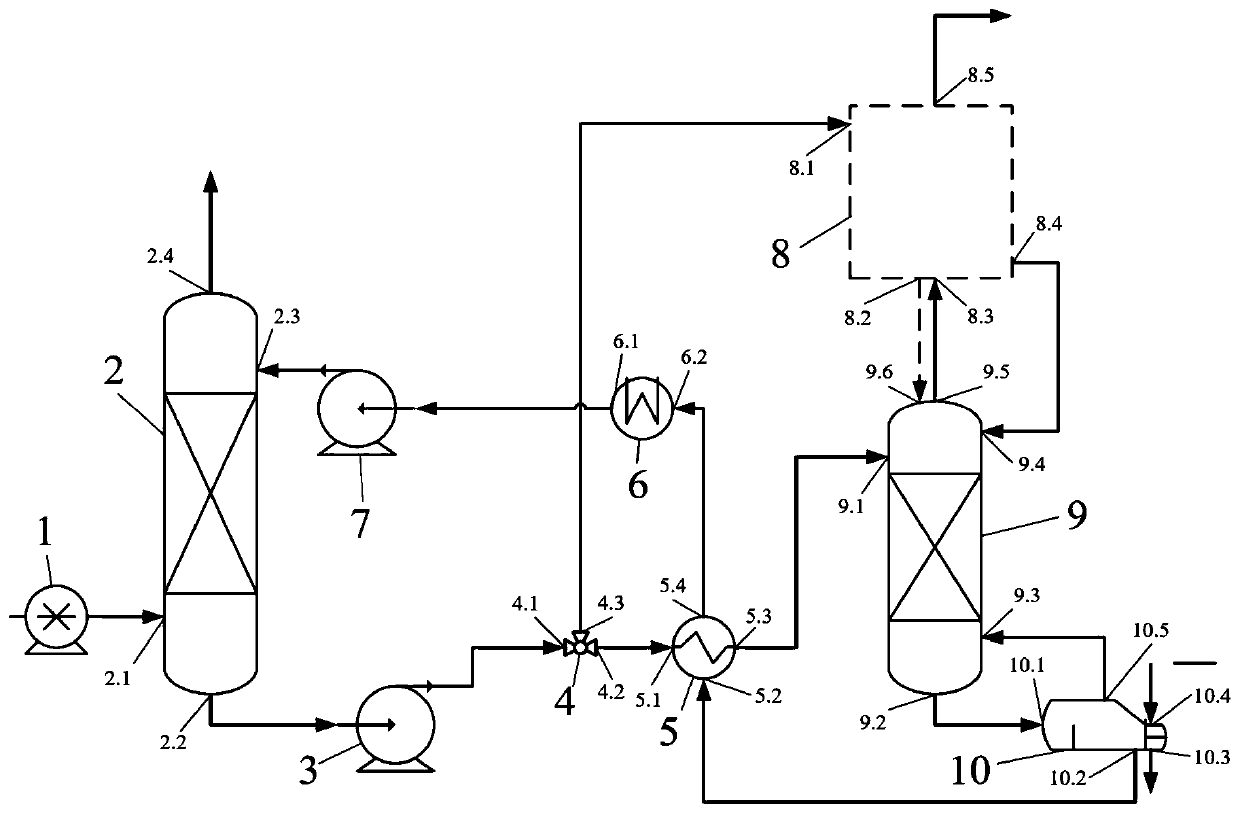

CO2 chemical absorption system and method for reinforcing waste heat recovery of hydrophilic and hydrophobic double-membrane heat exchangers

A waste heat recovery and chemical absorption technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as the limitation of heat transfer mode, and achieve the effect of strengthening waste heat recovery performance, convenient loading and unloading, and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

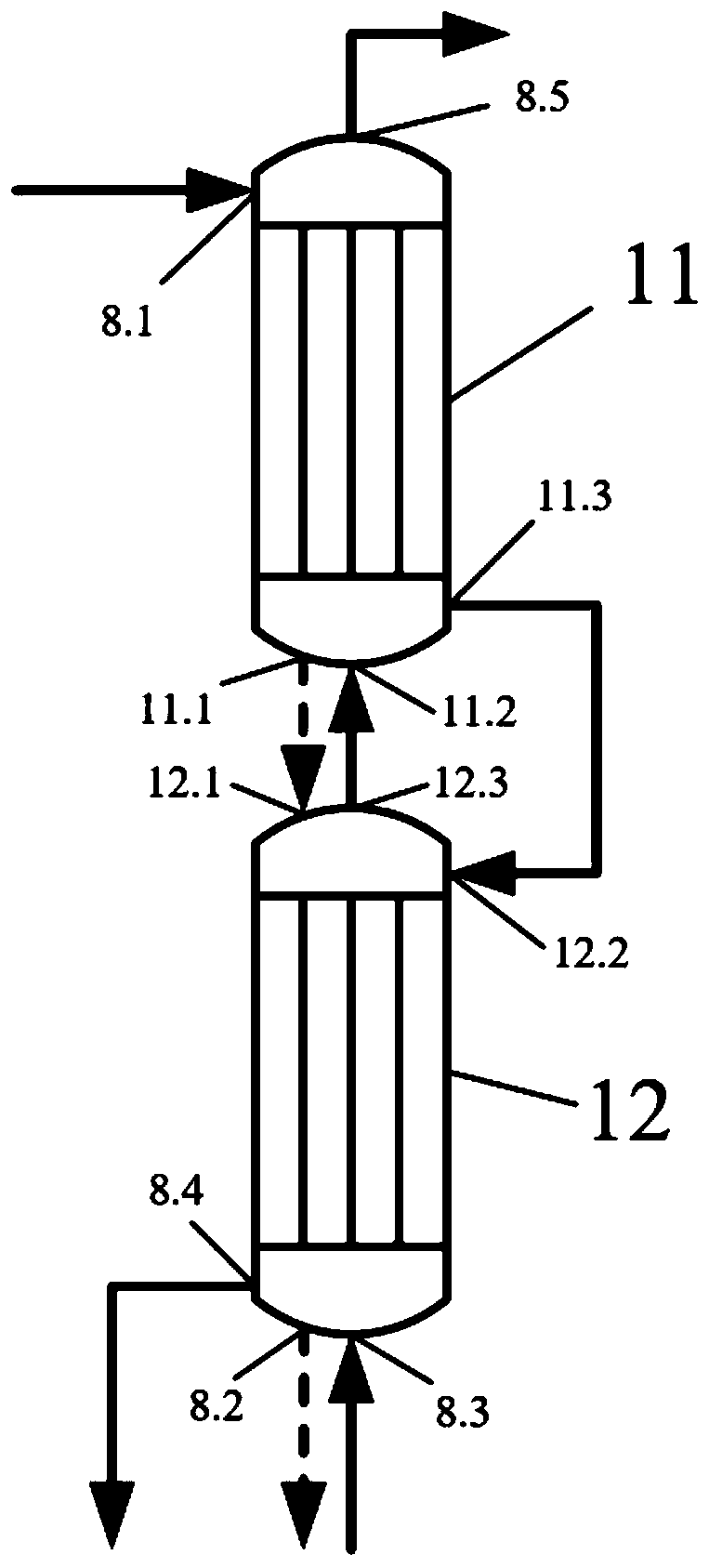

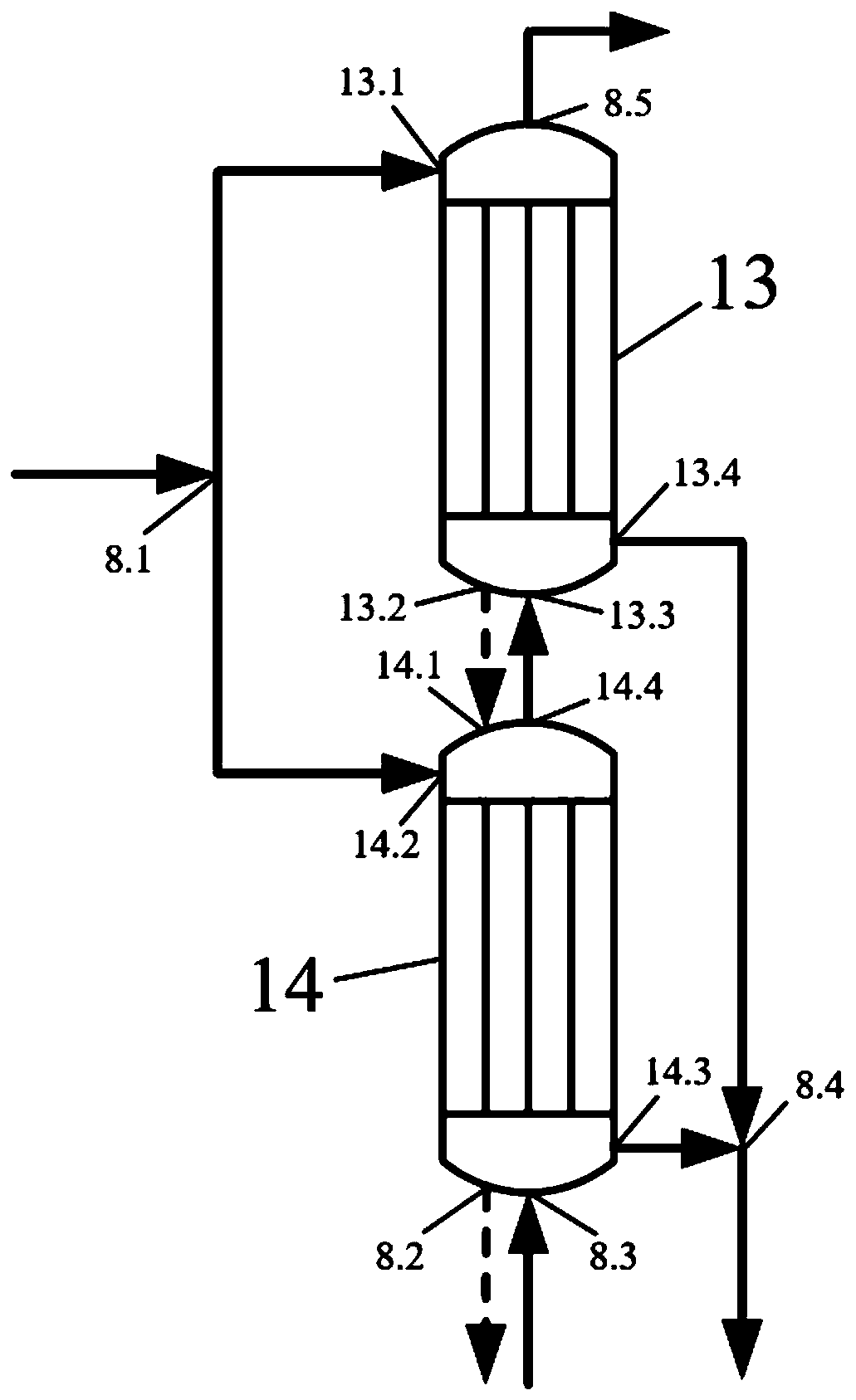

[0028] High-temperature-resistant hydrophobic porous membranes (such as polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF)) are often used for water vapor separation, which can block liquid water at the gas-film interface, and water vapor can pass through the pores by virtue of partial pressure. Membrane, whose separation mechanism will facilitate the recovery of water vapor. In addition, hydrophilic porous membranes (such as ceramic membranes, polyetheretherketone (PEEK)) affected by capillary condensation or multilayer diffusion will facilitate the joint transfer of liquid water and water vapor. Based on this, in order to enhance the performance of membrane waste heat recovery and adapt to large-scale industrial waste heat recovery applications, it is proposed to use hydrophobic membrane heat exchangers and hydrophilic membrane hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com