A kind of preparation method of wood-based flexible composite electrode material

A composite electrode and base flexible technology, which is applied in the field of wood-based energy storage materials, can solve the problems of complex preparation process and poor flexibility, and achieve the effects of high conductivity, improved electrochemical performance, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

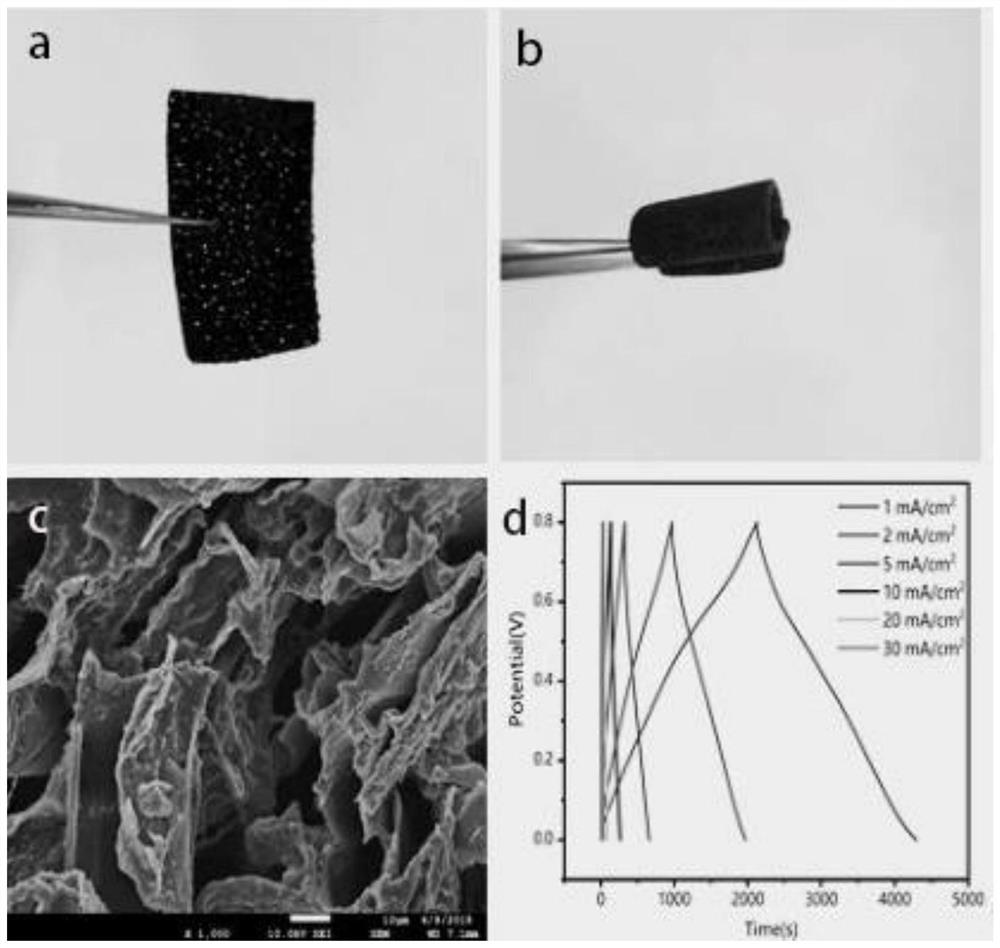

Image

Examples

Embodiment 1

[0043] (1) The balsa wood is sliced along the growth direction to obtain a wood substrate with a thickness of 0.5mm and a length and width of 4.5×2.5mm.

[0044] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0045] (3) Put the sample in step (2) into 2.5mol / L NaOH and 0.4mol / L NaOH 2 SO 3 In the mixed aqueous solution, heat in a water bath at 90°C for 90min.

[0046] (4) The delignified wood substrate in step (3) was washed sequentially with ethanol and deionized water, and the sample was first frozen in a refrigerator for 12 hours, and then transferred to a freeze dryer for freeze-drying at -45°C for 36 hours.

[0047] (5) Pretreat the carbon nanotube powder with concentrated sulfuric acid and nitric acid, add acetone solution, ultrasonically disperse for 1-2 hours, centrifuge with a high-speed centrifuge, and take the upper layer solution to obtain an...

Embodiment 2

[0054] (1) Slice the balsa wood along the growth direction to obtain a wood substrate with a thickness of 0.5 mm and a length and width of 4.5×2.5 mm.

[0055] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0056] (3) Dip the wood substrate in step (2) into NaClO 2 solution, with CH 3 Adjust the pH to 4.6 with COOH, heat and boil for 1h.

[0057] (4) The delignified wood substrate in step (3) was washed sequentially with ethanol and deionized water, and the sample was first frozen in a refrigerator for 12 hours, and then transferred to a freeze dryer for freeze-drying at -45°C for 36 hours.

[0058] (5) Pretreat the carbon nanotube powder with concentrated sulfuric acid and nitric acid, add acetone solution, ultrasonically disperse for 1-2 hours, centrifuge with a high-speed centrifuge, and take the upper layer solution to obtain an acetone dispersion of m...

Embodiment 3

[0065] (1) Slice poplar wood along the growth direction to obtain a wood substrate with a thickness of 0.5 mm and a length and width of 4.5×2.5 mm.

[0066] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0067] (3) Put the wood substrate in step (2) into 2.5mol / L NaOH and 0.4mol / L NaOH 2 SO 3 In the mixed aqueous solution, heat in a water bath at 90°C for 90min.

[0068] (4) The delignified wood substrate in step (3) was washed sequentially with ethanol and deionized water, and the sample was first frozen in a refrigerator for 12 hours, and then transferred to a freeze dryer for freeze-drying at -45°C for 36 hours.

[0069] (5) Pretreat the carbon nanotube powder with concentrated sulfuric acid and nitric acid, add acetone solution, ultrasonically disperse for 1-2 hours, centrifuge with a high-speed centrifuge, and take the upper layer solution to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com