One-step dyeing method of cool air layer bedding fabric

An air layer, dyeing technology, applied in the field of fabrics in the textile industry, can solve problems such as difficult to solve dyeing problems, and achieve the effects of dimensional stability, low thermal resistance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0039] The technological process of the present invention is as follows: greige cloth is degreased and washed with water → color paste configuration → three dipping and three rolling → drying → baking → finished product.

[0040] 1. Specifications of gray fabric

[0041] The fabric is a three-layer knitted jacquard air layer structure;

[0042] The noodles are 400D ultra-high molecular weight polyethylene filaments with a content of 15%;

[0043] The bottom yarn is 200D polyester filament, the content is 35%;

[0044] The middle is 150D polyester low elastic yarn, the content is 50%;

[0045] Gram weight is 240g / m 2 , a width of 240cm, and a thickness of 0.5mm. 2. Fabric pretreatment

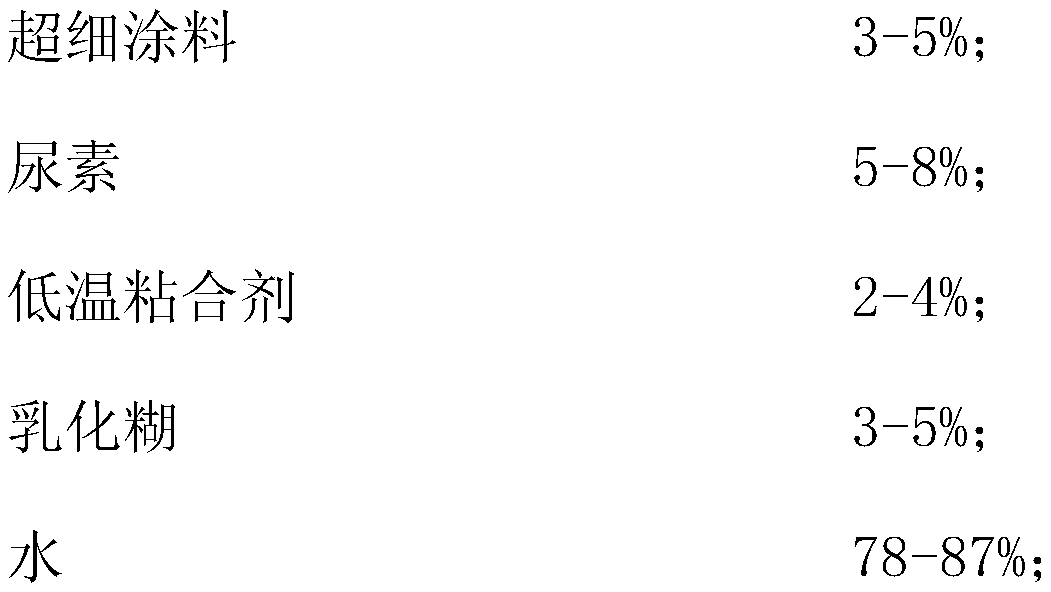

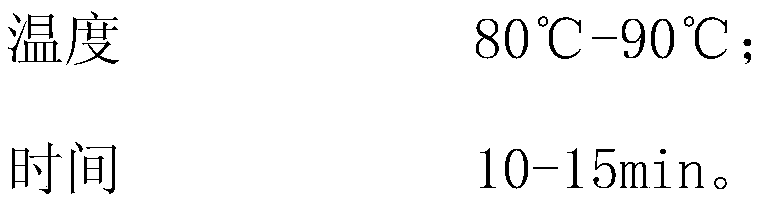

[0046] Process Prescription and Conditions:

[0047]

[0048] 3. Padding

[0049] 3.1 One dipping and one rolling

[0050] Process prescriptions and conditions are as follows:

[0051] Modified silicone hydrophilic softener: 10g / L;

[0052] Temperature: 20°C;

[0053] Surplus rate ...

specific Embodiment 2

[0066] The technological process of the present invention is as follows: greige cloth is degreased and washed with water → color paste configuration → three dipping and three rolling → drying → baking → finished product.

[0067] 1. Specifications of gray fabric

[0068] The fabric is a three-layer knitted jacquard air layer structure;

[0069] The noodles are 400D ultra-high molecular weight polyethylene filaments with a content of 15%;

[0070] The bottom yarn is 200D polyester filament, the content is 35%;

[0071] The middle is 150D polyester low elastic yarn, the content is 50%;

[0072] Gram weight is 250g / m 2 , a width of 245cm, and a thickness of 0.6mm.

[0073] 2. Fabric pretreatment

[0074] Process Prescription and Conditions:

[0075]

[0076] 3. Padding

[0077] 3.1 One dipping and one rolling

[0078]Process prescriptions and conditions are as follows:

[0079] Modified silicone hydrophilic softener: 20g / L;

[0080] Temperature: 25°C;

[0081] Surpl...

specific Embodiment 3

[0094] The technological process of the present invention is as follows: greige cloth is degreased and washed with water → color paste configuration → three dipping and three rolling → drying → baking → finished product.

[0095] 1. Specifications of gray fabric

[0096] The fabric is a three-layer knitted jacquard air layer structure;

[0097] The noodles are 400D ultra-high molecular weight polyethylene filaments with a content of 15%;

[0098] The bottom yarn is 200D polyester filament, the content is 35%;

[0099] The middle is 150D polyester low elastic yarn, the content is 50%;

[0100] Gram weight is 246g / m 2 , a width of 243cm, and a thickness of 0.58mm.

[0101] 2. Fabric pretreatment

[0102] Process Prescription and Conditions:

[0103]

[0104] 3. Padding

[0105] 3.1 One dipping and one rolling

[0106] Process prescriptions and conditions are as follows:

[0107] Modified silicone hydrophilic softener: 14g / L;

[0108] Temperature: 22°C;

[0109] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com